This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

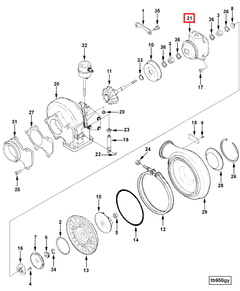

The H2 Turbo Bearing Housing, identified by part number 3528207, is a component manufactured by Cummins, a well-established name in the automotive industry, particularly in the realm of heavy-duty truck engines. This bearing housing is integral to the turbocharger system, which plays a role in enhancing the performance and efficiency of diesel engines.

Basic Concepts

To understand the H2 Turbo Bearing Housing, it is important to grasp the fundamental concepts of turbo bearing housings and their role within turbocharger systems. Turbochargers operate on the principle of compressing the air entering the engine, which allows for more fuel to be burned and thus increases power output. The turbo bearing housing encases and supports the turbocharger’s rotating components, ensuring smooth operation and efficiency 1.

Purpose and Function

The H2 Turbo Bearing Housing serves a pivotal role in the operation of a heavy-duty truck. It supports the turbocharger’s rotating components, which include the turbine and compressor wheels. By providing a stable and secure environment for these components, the bearing housing helps maintain the turbocharger’s efficiency and, by extension, the engine’s performance. It ensures that the turbocharger operates within its designed parameters, contributing to the overall effectiveness of the engine 2.

Key Features

The H2 Turbo Bearing Housing is characterized by several key features that enhance its functionality and reliability. Its construction is durable, designed to withstand the high temperatures and pressures associated with turbocharger operation. Precision engineering ensures that the housing fits snugly and functions correctly within the turbocharger assembly. Additionally, it is specifically engineered to be compatible with Cummins engines, ensuring optimal performance and integration.

Benefits

Utilizing the H2 Turbo Bearing Housing offers several advantages. It contributes to improved engine efficiency by supporting the turbocharger’s operation, which in turn enhances the engine’s power output. The durable construction and precision engineering of the housing contribute to the turbocharger’s longevity, reducing the likelihood of premature failure. Furthermore, its reliable performance under demanding conditions makes it a valuable component for heavy-duty applications 3.

Installation and Compatibility

Proper installation of the H2 Turbo Bearing Housing is crucial for ensuring its effectiveness and the overall performance of the turbocharger. While specific installation procedures may vary, it is generally recommended to follow the manufacturer’s guidelines to ensure correct fitting and operation. The housing is designed to be compatible with specific Cummins engine models, ensuring seamless integration and optimal performance.

Maintenance and Troubleshooting

Routine maintenance of the H2 Turbo Bearing Housing is important for ensuring its longevity and performance. This includes regular inspection for signs of wear or damage, ensuring that all connections are secure, and adhering to lubrication requirements as specified by the manufacturer. Common troubleshooting techniques may involve checking for unusual noises, vibrations, or performance issues, which could indicate problems with the bearing housing or other turbocharger components.

Performance Enhancements

The use of the H2 Turbo Bearing Housing can lead to performance enhancements in the turbocharger and, by extension, the engine. These may include increased turbocharger responsiveness, leading to quicker acceleration, and improved engine power output. The precise engineering and durable construction of the housing contribute to these performance gains by ensuring efficient and reliable turbocharger operation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a rich history dating back to 1919, Cummins has established a strong reputation in the automotive industry for quality, innovation, and reliability. The H2 Turbo Bearing Housing is part of Cummins’ extensive portfolio of components designed to enhance the performance and efficiency of heavy-duty truck engines.

Compatibility with Cummins Engines

The H2 Turbo Bearing Housing, identified by the part number 3528207, is designed to fit seamlessly with several Cummins engine models. This part is integral to the turbocharging system, ensuring efficient and reliable operation of the engine. Below is a detailed description of its compatibility with specific Cummins engines:

4B3.9 and 6B5.9 Engines

The 3528207 turbo bearing housing is specifically engineered to fit the 4B3.9 and 6B5.9 engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The turbo bearing housing plays a pivotal role in supporting the turbocharger, ensuring that it operates smoothly and efficiently. Its design allows for precise alignment and minimal friction, which is crucial for maintaining the longevity and performance of the turbocharger.

6C8.3 Engine

Similar to the 4B3.9 and 6B5.9 engines, the 6C8.3 engine also benefits from the 3528207 turbo bearing housing. This engine is another member of the Cummins lineup that demands high reliability and performance, typically used in various industrial and commercial applications. The turbo bearing housing in this context ensures that the turbocharger is securely mounted and operates without undue stress, contributing to the overall efficiency and durability of the engine.

ISB CM550 Engine

The ISB CM550 engine is another significant model that is compatible with the 3528207 turbo bearing housing. This engine is renowned for its power and efficiency, often utilized in on-highway and vocational applications. The turbo bearing housing for the ISB CM550 is designed to handle the specific demands of this engine, providing a stable platform for the turbocharger and ensuring optimal performance under various operating conditions.

Grouping of Engines

The engines listed—4B3.9, 6B5.9, 6C8.3, and ISB CM550—share common design principles and performance characteristics, making the 3528207 turbo bearing housing a versatile component across these models. This compatibility underscores the importance of using the correct turbo bearing housing to maintain the integrity and performance of these engines.

Role of Part 3528207 H2 Turbo Bearing Housing in Engine Systems

The H2 Turbo Bearing Housing, identified by part number 3528207, is an integral component in the assembly and operation of various turbocharger systems. This component is specifically designed to house and support the bearings within the turbocharger, ensuring smooth and efficient rotation of the turbine and compressor wheels.

Integration with Turbocharger Core Assemblies

When integrating with core assemblies such as the H1E, H1C, WH1C, WH1E, and WHIE, the H2 Turbo Bearing Housing plays a significant role in maintaining the structural integrity and operational efficiency of the turbocharger. It securely holds the bearings in place, allowing for precise alignment and reduced friction as the turbocharger spins at high speeds. This is essential for the reliable performance of the core assembly, as any misalignment or excessive friction can lead to decreased efficiency and potential failure of the turbocharger.

Function within Aftermarket Turbochargers

In aftermarket turbochargers, the H2 Turbo Bearing Housing is often a key upgrade component. It provides enhanced support for the bearings, which is particularly important in high-performance applications where the turbocharger operates under extreme conditions. The housing ensures that the bearings remain cool and lubricated, which is vital for the longevity and performance of the turbocharger.

Contribution to Turbocharger Kits

Within turbocharger kits, the H2 Turbo Bearing Housing is a fundamental piece that contributes to the overall effectiveness of the kit. These kits often include various components designed to upgrade or replace existing turbocharger parts. The bearing housing, by ensuring proper bearing function, helps in achieving the desired performance gains and reliability improvements that the kit promises.

Importance in Turbocharger Location

The location of the turbocharger in an engine system also influences the role of the H2 Turbo Bearing Housing. Whether the turbocharger is positioned on the exhaust side (turbo-after) or integrated within the engine bay, the bearing housing must withstand the specific thermal and mechanical stresses associated with that location. Its design considerations include thermal expansion management and vibration damping, which are critical for maintaining optimal turbocharger performance.

Overall Impact on Turbocharger Performance

Ultimately, the H2 Turbo Bearing Housing is a component that significantly impacts the performance and durability of turbochargers across various engine systems. By providing a stable and secure environment for the bearings, it enables the turbocharger to operate efficiently, contributing to improved engine performance, increased power output, and enhanced fuel efficiency.

Conclusion

The H2 Turbo Bearing Housing, part number 3528207, is a critical component in the turbocharger systems of Cummins engines. Its role in supporting the turbocharger’s rotating components ensures efficient and reliable engine operation. The durable construction, precision engineering, and compatibility with specific Cummins engine models make it a valuable asset for enhancing engine performance and longevity.

-

Garrett, T.K., Newton, K., & Steeds, W. (2001). The Motor Vehicle. Reed Educational and Professional Publishing Ltd.

↩ -

Awari, G.K., Kumbhar, V.S., & Tirpude, R.B. (2011). Automotive Systems Principles and Practice. CRC Press.

↩ -

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.