This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

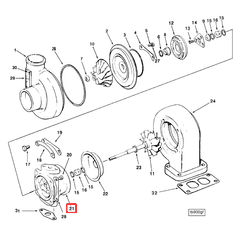

The H2 Turbo Bearing Housing (Part #3520702) by Cummins is a vital component in the turbocharger system of heavy-duty trucks. Manufactured by Cummins, a renowned leader in the automotive industry, this bearing housing is designed to enhance the performance and reliability of turbochargers used in various engine applications.

Basic Concepts

To understand the H2 Turbo Bearing Housing, it is important to first grasp the fundamentals of turbochargers and bearing housings. A turbocharger is a device that increases an engine’s efficiency and power output by forcing extra air into the combustion chamber. This process, known as forced induction, allows more fuel to be burned, resulting in greater power production without a corresponding increase in engine size 1.

A bearing housing is a component that encloses and supports the bearings within a turbocharger. Bearings are essential for allowing the turbocharger’s rotor to spin at high speeds with minimal friction. The H2 Turbo Bearing Housing specifically plays a role in supporting the turbocharger’s rotating components, ensuring smooth operation and efficient airflow 2.

Purpose and Function

The H2 Turbo Bearing Housing serves a pivotal role in the operation of a truck’s engine. It supports the turbocharger’s rotating components, which include the turbine and compressor wheels. By providing a stable and secure environment for these components, the bearing housing helps maintain the turbocharger’s efficiency and performance. This, in turn, contributes to improved airflow within the engine, enhancing overall engine performance 3.

Key Features

The H2 Turbo Bearing Housing is characterized by several key features that contribute to its effectiveness and durability. These include:

- Durable Construction: The bearing housing is made from high-quality materials that can withstand the high temperatures and pressures encountered in a turbocharger environment.

- Precision Engineering: The housing is engineered to exacting standards to ensure optimal fit and function within the turbocharger system.

- Compatibility: Designed specifically for use with Cummins engines, the H2 Turbo Bearing Housing ensures seamless integration and performance.

Benefits

The incorporation of the H2 Turbo Bearing Housing into a truck’s engine system offers several benefits:

- Improved Engine Performance: By supporting the turbocharger’s rotating components, the bearing housing helps maintain efficient airflow, which can lead to enhanced engine performance.

- Enhanced Fuel Efficiency: Efficient airflow and turbocharger operation can contribute to better fuel economy, making the vehicle more cost-effective to operate.

- Increased Reliability: The durable construction and precision engineering of the bearing housing contribute to the overall reliability of the turbocharger system.

Installation and Compatibility

Proper installation of the H2 Turbo Bearing Housing is crucial for ensuring optimal performance and longevity. While specific installation procedures may vary depending on the engine model, it is generally recommended to follow the manufacturer’s guidelines for best results. The bearing housing is compatible with various Cummins engine models, ensuring a wide range of applications 4.

Maintenance and Troubleshooting

Routine maintenance of the H2 Turbo Bearing Housing is important for preserving its performance and longevity. This may include regular inspections for signs of wear or damage, as well as cleaning to remove any buildup that could affect operation. Common signs of wear or failure may include unusual noises from the turbocharger, decreased engine performance, or visible damage to the bearing housing. Troubleshooting tips may involve checking for proper installation, ensuring compatibility with the engine, and addressing any issues promptly to prevent further damage 5.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive industry. The company’s product offerings cater to various applications, from on-highway and off-highway vehicles to industrial and power generation equipment.

Role of Part 3520702 H2 Turbo Bearing Housing in Engine Systems

The H2 Turbo Bearing Housing, identified by part number 3520702, is an integral component in the assembly and operation of various turbocharger systems. Its primary function is to house and support the turbocharger’s bearings, ensuring smooth and efficient rotation of the turbine and compressor wheels.

Integration with Aftermarket Turbocharger

When installing an aftermarket turbocharger, the H2 Turbo Bearing Housing is essential for maintaining the structural integrity and performance of the turbocharger. It interfaces directly with the turbocharger’s core assembly, providing a stable foundation for the high-speed rotating components. This housing ensures that the turbocharger operates within specified tolerances, enhancing overall engine performance and reliability.

Core and Housing Kit

In a core and housing kit, the H2 Turbo Bearing Housing plays a pivotal role by securing the turbocharger’s core components. This kit often includes the compressor wheel, turbine wheel, and center housing. The bearing housing ensures these elements are aligned correctly, reducing friction and wear, which is vital for the longevity and efficiency of the turbocharger.

Turbocharger Kit H1E Auto and H1E Indicator

For specialized applications such as the Turbocharger Kit H1E Auto and H1E Indicator, the H2 Turbo Bearing Housing is crucial for precise operation. These kits are designed for specific engine configurations and performance requirements. The bearing housing must be meticulously fitted to ensure that the turbocharger’s electronic indicators and automatic functions operate correctly, providing real-time data and adjustments for optimal performance.

Engine Oil Cooler

The H2 Turbo Bearing Housing also interacts with the engine oil cooler system. Proper lubrication is essential for the bearings within the housing, and the oil cooler ensures that the oil remains at an optimal temperature. This integration helps in maintaining the viscosity of the lubricant, which is necessary for reducing friction and preventing overheating of the turbocharger’s moving parts.

General Turbocharger Systems

Across various turbocharger systems, the H2 Turbo Bearing Housing is a fundamental component. It supports the turbocharger’s internal bearings, which are subject to high rotational speeds and loads. The housing must be robust yet precisely machined to accommodate these demands, ensuring that the turbocharger can handle the increased airflow and pressure without compromising performance or durability.

Conclusion

In summary, the H2 Turbo Bearing Housing (part 3520702) is a key element in the efficient and reliable operation of turbocharger systems. Its role in supporting and aligning critical components, ensuring proper lubrication, and integrating with other engine systems underscores its importance in enhancing engine performance and durability.

-

Sheng, G. (2012). Vehicle Noise, Vibration and Sound Quality. SAE International.

↩ -

Reif, K. Ed. (2014). Brakes Brake Control and Driver Assistance Systems Function Regulation and Components. Springer.

↩ -

Khajepour, A. (2023). Synthesis Lectures on Advances in Automotive Technology. Springer.

↩ -

Peters, G., & Peters, B. J. (2002). Automobile Vehicle Safety. CRC Press.

↩ -

General Information, Bulletin Number 4021619, Operation and Maintenance Manual.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.