This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

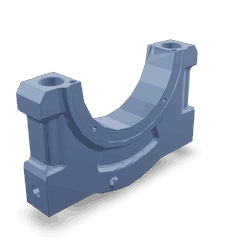

The Cummins 3429113 Main Bearing Cap is a component designed for use in heavy-duty truck engines. It plays a role in the engine’s operation by supporting the crankshaft and ensuring proper alignment and lubrication of the main bearings. This part contributes to the overall efficiency and reliability of the vehicle 1.

Basic Concepts of Main Bearing Caps

A main bearing cap is a component in an engine’s crankshaft support system. Its primary function is to secure the main bearings in place, which are responsible for supporting the crankshaft’s rotation. By maintaining proper alignment and ensuring consistent lubrication, the main bearing cap contributes to the engine’s smooth operation, durability, and performance 2.

Purpose of the Cummins 3429113 Main Bearing Cap

The Cummins 3429113 Main Bearing Cap provides structural support to the crankshaft. It ensures that the main bearings remain properly aligned and lubricated, which is essential for the crankshaft’s rotation and the engine’s overall performance. This cap is designed to withstand the high pressures and temperatures within the engine, contributing to the engine’s durability and efficiency 3.

Key Features

The Cummins 3429113 Main Bearing Cap is characterized by several key features that enhance its performance and reliability. It is constructed from high-quality materials that offer superior strength and resistance to wear. The design includes precise machining for optimal fit and alignment, ensuring that the main bearings operate within specified tolerances. Additionally, the cap may feature unique characteristics such as oil passages or relief grooves to improve lubrication and cooling, further enhancing its performance 4.

Benefits of Using Cummins 3429113 Main Bearing Cap

Utilizing the Cummins 3429113 Main Bearing Cap offers several advantages. Its robust construction and precise design contribute to improved engine efficiency by ensuring optimal crankshaft support and alignment. The cap’s durability and reliability help to extend the engine’s lifespan, reducing the need for frequent replacements or repairs. Furthermore, the enhanced lubrication provided by the cap’s design helps to minimize friction and wear, contributing to the engine’s overall performance and longevity 1.

Installation and Maintenance

Proper installation of the Cummins 3429113 Main Bearing Cap is crucial for ensuring optimal engine performance. It should be installed according to the manufacturer’s torque specifications and alignment procedures to guarantee a secure fit and proper function. Regular maintenance, including inspection for wear or damage and ensuring adequate lubrication, is essential for prolonging the cap’s lifespan and maintaining engine efficiency. Following these guidelines helps to ensure the longevity and optimal performance of the engine 2.

Troubleshooting Common Issues

Common issues associated with main bearing caps include wear, misalignment, and lubrication problems. These issues can lead to increased friction, reduced engine efficiency, and potential damage to the crankshaft and bearings. To address these problems, it is important to conduct regular inspections and maintenance. If wear or damage is detected, the cap should be replaced to prevent further engine damage. Ensuring proper lubrication and alignment during installation can help to prevent these issues from occurring 3.

Cummins: A Brief Overview

Cummins Inc. is a global leader in the design, manufacture, and distribution of diesel and alternative fuel engines, as well as related technologies. With a history spanning over a century, Cummins has established a reputation for producing high-quality, reliable engines and components for a wide range of applications, including heavy-duty trucks. The company’s commitment to innovation, quality, and customer satisfaction has made it a trusted name in the automotive industry 4.

Cummins Main Bearing Cap 3429113 Compatibility

The Cummins Main Bearing Cap 3429113 is designed to fit seamlessly with a range of Cummins engines, ensuring optimal performance and reliability. This part is integral to the engine’s operation, providing a secure interface between the crankshaft and the engine block.

Compatible Engines

- QSV81G, QSV91G, QSW/QSV82, and QSW73

These engines share a similar design and architecture, making the Main Bearing Cap 3429113 a versatile component across these models. The cap’s precision engineering ensures it fits snugly, reducing friction and wear, which is crucial for maintaining engine efficiency and longevity.

- QSV91-G4 CM558/CM700 V102

This engine, while part of a different series, also benefits from the Main Bearing Cap 3429113. The cap’s design is tailored to accommodate the unique specifications of this engine, ensuring a perfect fit and reliable operation.

Key Considerations

When installing the Main Bearing Cap 3429113, it is essential to follow the manufacturer’s guidelines to ensure proper alignment and fit. This component is critical for the engine’s structural integrity, and any deviation from recommended installation procedures could lead to performance issues or engine damage.

Installation Tips

- Cleanliness: Ensure all mating surfaces are clean and free of debris before installation.

- Torque Specifications: Adhere to the specified torque values to avoid over-tightening or under-tightening.

- Alignment: Proper alignment of the bearing cap is crucial to prevent misalignment and potential engine damage.

By following these guidelines, the Cummins Main Bearing Cap 3429113 will provide reliable support and performance across the compatible engine models.

Role of Part 3429113 Main Bearing Cap in Engine Systems

The part 3429113 Main Bearing Cap is an integral component in the assembly and operation of various engine systems. It works in conjunction with several key components to ensure the smooth and efficient functioning of the engine.

Integration with the Block and Cylinder Assembly

The Main Bearing Cap is bolted to the Block and Cylinder Assembly Block, providing a secure foundation for the crankshaft’s main bearings. This arrangement is essential for maintaining the structural integrity of the Cylinder Block and Cylinder Block Kit. The cap helps in distributing the loads exerted by the crankshaft, thereby reducing stress on the block and ensuring consistent engine performance.

Interaction with the Gear and Camshaft System

In engines equipped with a Camshaft and Idler Gear system, the Main Bearing Cap plays a supportive role. It ensures that the crankshaft, which drives the camshaft via the idler gear, remains stable and aligned. This stability is vital for the precise timing and operation of the valvetrain, directly influencing the engine’s efficiency and power output.

Contribution to Prechamber Bits and QSV Systems

For engines utilizing Prechamber Bits and QSV (Quadrant Spark Valve) technology, the Main Bearing Cap contributes to the overall engine balance. By securing the crankshaft in place, it allows for the consistent ignition timing required by these advanced combustion systems. This results in improved fuel efficiency and reduced emissions.

Compatibility with D67 Engines

In D67 engine systems, the Main Bearing Cap is particularly important due to the high-performance nature of these engines. It ensures that the crankshaft can withstand the increased loads and stresses, maintaining engine reliability under demanding conditions. The cap’s design and material are tailored to handle the specific requirements of the D67 engine, enhancing its durability and performance.

Conclusion

The Cummins 3429113 Main Bearing Cap is a critical component in heavy-duty truck engines, ensuring the proper alignment and lubrication of the main bearings. Its robust construction, precise design, and compatibility with various Cummins engines contribute to the engine’s efficiency, durability, and performance. Proper installation and maintenance are essential for maximizing the benefits of this part and ensuring the longevity of the engine.

-

Bari, S. (2013). Diesel Engine Combustion, Emissions and Condition Monitoring. InTech.

↩ ↩ -

Bennett, S. (2012). Modern Diesel Technology: Light Duty Diesels. Cengage Learning.

↩ ↩ -

Garrett, T.K., Newton, K., & Steeds, W. (2001). The Motor Vehicle. Reed Educational and Professional Publishing Ltd.

↩ ↩ -

Fijalkowski, B.T. (2011). Automotive Mechatronics Operational and Practical Issues Volume 1. Springer.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.