This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

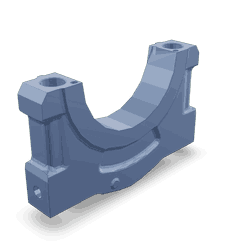

The Cummins 3428110 Main Bearing Cap is a critical component in heavy-duty truck engines, designed to support the crankshaft and enhance engine stability and efficiency. This part ensures smooth and reliable engine performance under demanding conditions.

Function and Operation

The Main Bearing Cap secures the main bearings in place, providing essential support for the crankshaft. This support is crucial for maintaining engine stability and ensuring the crankshaft operates within precise tolerances. The cap, in conjunction with the main bearings, reduces friction and wear, contributing to the engine’s longevity and performance. By providing a stable foundation for the crankshaft, the cap helps maintain alignment and minimize vibrations, enhancing overall engine efficiency 1.

Key Features

The Cummins 3428110 Main Bearing Cap is characterized by its precision machining and durable material construction. These features ensure a perfect fit and long-lasting performance. The cap is manufactured to strict specifications, guaranteeing compatibility with Cummins engines and contributing to the engine’s reliability. Its design incorporates advanced materials that offer resistance to wear and corrosion, further enhancing its durability and performance 2.

Benefits

The advantages provided by the Cummins 3428110 Main Bearing Cap include enhanced engine performance, longevity, and reliability. By effectively supporting the crankshaft, it contributes to smoother engine operation and reduces the likelihood of premature wear. This part ensures that the crankshaft and main bearings function optimally, leading to improved fuel economy and reduced maintenance requirements 3.

Installation Process

Proper installation of the Cummins 3428110 Main Bearing Cap is essential for ensuring optimal performance. The process involves careful alignment of the cap with the engine block and crankshaft, followed by securing it with the appropriate torque specifications. It is important to follow best practices during installation to avoid issues such as misalignment or improper fit, which could lead to engine performance problems.

Common Issues and Troubleshooting

Typical problems associated with main bearing caps include misalignment, wear, and oil starvation. Misalignment can lead to increased friction and wear on the crankshaft and bearings, while wear may result from insufficient lubrication or high operating temperatures. Oil starvation, often caused by clogged oil passages or insufficient oil pressure, can also contribute to premature wear. Diagnostic procedures may involve inspecting the cap and bearings for signs of wear, checking oil passages for blockages, and ensuring proper alignment and fit. Corrective actions may include cleaning or replacing oil passages, adjusting alignment, or replacing worn components.

Maintenance Tips

Regular inspection and maintenance of the Cummins 3428110 Main Bearing Cap are recommended to ensure continued engine performance and longevity. This includes monitoring lubrication levels and quality, checking for signs of wear or damage, and adhering to recommended replacement intervals. Proper lubrication practices are vital for reducing friction and wear, while regular inspections can help identify potential issues before they lead to significant engine problems.

Cummins Overview

Cummins Inc. is a well-established company with a strong reputation in the automotive and heavy-duty truck industry. Founded in 1919, Cummins has a history of innovation and quality in engine component manufacturing. The company is known for its commitment to producing reliable and efficient engine parts, including the Cummins 3428110 Main Bearing Cap, which reflects Cummins’ dedication to excellence and customer satisfaction.

Compatibility

The Cummins Main Bearing Cap part number 3428110 is designed to fit a variety of Cummins engines, ensuring a secure and reliable connection between the crankshaft and engine block. This part is crucial for maintaining the structural integrity of the engine by supporting the main bearings and reducing friction.

Compatible Engines

- QSV81G

- QSV91-G4 CM558/CM700 V102

- QSV91G

- QSW/QSV82

- QSW73

These engines, while differing in specific configurations and applications, share a common design that allows the use of the same main bearing cap. This compatibility ensures that the part can be used across multiple engine models, simplifying maintenance and repair processes.

Installation and Usage

When installing the Main Bearing Cap 3428110, it is essential to follow proper procedures to ensure a secure fit and optimal performance. This includes:

- Cleaning: Ensure the mating surfaces are clean and free of debris to prevent any interference with the bearing cap’s function.

- Alignment: Properly align the bearing cap with the engine block and crankshaft to avoid misalignment issues.

- Torque Specifications: Adhere to the manufacturer’s torque specifications to ensure the bearing cap is tightened correctly, preventing any potential failure.

Importance of Proper Fitment

Using the correct main bearing cap is vital for the longevity and efficiency of the engine. An improperly fitted bearing cap can lead to increased friction, wear, and potential engine damage. The compatibility of the 3428110 part number across the listed engines highlights its versatility and importance in maintaining engine performance.

Integration of Part 3428110 Main Bearing Cap in Engine Systems

The Main Bearing Cap (part 3428110) is a critical component in the assembly and operation of various engine systems. Its primary function is to secure the main bearings in place, ensuring the crankshaft rotates smoothly within the engine block.

Interaction with Engine Block and Cylinder Components

The Main Bearing Cap is bolted to the Cylinder Block, which houses the engine’s cylinders. This cap provides structural support and maintains the alignment of the crankshaft journal. In a Cylinder Assembly Block or a Cylinder Block Kit, the cap ensures that the main bearings are correctly positioned, reducing friction and wear on the crankshaft.

Role in Camshaft and Gear Systems

In engines equipped with a Camshaft, the Main Bearing Cap indirectly influences the timing and operation of the valve train. By ensuring the crankshaft’s stable rotation, the cap helps maintain consistent camshaft drive, which is often facilitated by Idler Gears in overhead camshaft (OHC) engines. Proper alignment and support from the cap are vital for the camshaft’s precise movement, affecting valve timing and engine performance.

Contribution to Prechamber and QSV Systems

In engines utilizing Prechamber Bits for combustion enhancement, the stability provided by the Main Bearing Cap is important. It ensures that the crankshaft’s movement is uniform, which is essential for the consistent operation of the prechamber system. Similarly, in engines with a QSV (Quiet Start Valve) system, the cap’s role in maintaining crankshaft stability contributes to the smooth start-up and operation of the engine.

Application in D67 Engines

For D67 engines, the Main Bearing Cap is particularly significant due to the high-performance nature of these engines. It ensures that the main bearings can withstand the increased loads and stresses, providing a stable environment for the crankshaft to operate efficiently. This is especially important in high-revving or high-torque applications where precision and durability are paramount.

Conclusion

The Cummins 3428110 Main Bearing Cap plays a supportive yet significant role in various engine systems, ensuring the crankshaft’s smooth operation and contributing to the overall efficiency and reliability of the engine. Proper installation, maintenance, and understanding of its function are essential for optimal engine performance.

-

Alma Hillier, Fundamentals of Motor Vehicle Technology Book 1 6th Edition, Oxford University Press, 2014.

↩ -

Arthur J Caines, Roger F Haycock, and John E Hillier, Automotive Lubricants Reference Book, SAE International, 2004.

↩ -

Arthur J Caines, Roger F Haycock, and John E Hillier, Automotive Lubricants Reference Book, SAE International, 2004.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.