This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

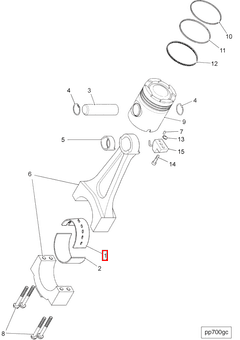

The Cummins 3424086 Connecting Rod Bearing is engineered for commercial truck engines, aiming to facilitate smooth operation between the connecting rod and the crankshaft. This part is crucial for efficient power transmission and engine performance, reducing friction and wear to enhance the engine’s durability and efficiency 2.

Basic Concepts of Connecting Rod Bearings

Connecting rod bearings are essential components within an engine, positioned between the connecting rod and the crankshaft. Their primary function is to minimize friction as the connecting rod oscillates during engine operation, maintaining engine performance and extending its operational life. These bearings are typically made from materials that can withstand high loads and temperatures, ensuring effective performance under demanding conditions 1.

Purpose of the Cummins 3424086 Connecting Rod Bearing

This Cummins part reduces friction and wear between the connecting rod and the crankshaft, allowing for smoother engine operation, enhancing efficiency and reliability. Its design is tailored to handle the specific stresses and loads encountered in commercial truck applications, contributing positively to the engine’s performance and longevity 2.

Key Features

The Cummins 3424086 Connecting Rod Bearing is characterized by several key features that enhance its performance and durability. These include a material composition designed to resist wear and corrosion, precision engineering for optimal fit and function, and a design that ensures efficient lubrication. These attributes collectively contribute to the bearing’s ability to operate under the high-stress conditions typical of commercial truck engines 2.

Benefits

Utilizing this part offers several benefits, including improved engine efficiency due to reduced friction, lower maintenance requirements thanks to its durable construction, and enhanced reliability, ensuring consistent performance over the engine’s lifespan. These advantages make it a valuable component for maintaining the operational integrity of commercial truck engines 2.

Installation and Maintenance

Proper installation of this Cummins part is crucial for ensuring its effective operation. Recommended procedures include careful handling to avoid contamination, precise alignment during installation, and ensuring proper lubrication. Maintenance tips include regular inspection for signs of wear or damage, maintaining clean oil to prevent contamination, and following manufacturer guidelines for replacement intervals to ensure the bearing operates efficiently throughout its lifespan 2.

Troubleshooting Common Issues

Common problems associated with connecting rod bearings, such as excessive wear or failure, can often be traced back to issues like inadequate lubrication, contamination, or misalignment during installation. Troubleshooting steps include inspecting the bearing and surrounding components for signs of damage, checking lubrication levels and quality, and ensuring the engine operates within specified parameters to prevent overheating or excessive stress on the bearing 2.

Compatibility with Cummins Engines

The 3424086 Connecting Rod Bearing is compatible with various Cummins engines, including the QSW/QSV82, QSW27, QSW36, and QSW73 engines. Its precision engineering ensures minimal wear and optimal performance, making it an essential component for maintaining the integrity of the engine’s internal mechanisms across different engine models 2.

Conclusion

The Cummins 3424086 Connecting Rod Bearing plays a significant role in the operation of commercial truck engines by reducing friction and wear between the connecting rod and the crankshaft. Its design and features contribute to the engine’s efficiency, reliability, and longevity. Proper installation, maintenance, and troubleshooting are essential for maximizing the benefits of this part, ensuring the engine operates at peak performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.