This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

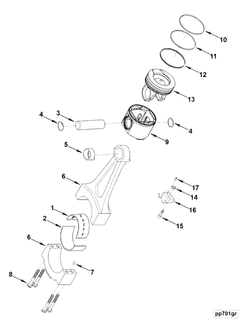

The Cummins 3424077 Connecting Rod Bearing is a specialized component designed for use in commercial truck engines. Its purpose is to facilitate the smooth operation of the engine by supporting the connecting rod and enabling efficient piston movement. This bearing is integral to maintaining the engine’s performance and reliability in demanding commercial applications.

Basic Concepts of Connecting Rod Bearings

Connecting rod bearings are components found in internal combustion engines. They function by providing a low-friction interface between the connecting rod and the crankshaft journal. This allows the connecting rod to pivot smoothly as the piston moves up and down. The bearing’s primary role is to reduce friction and wear, ensuring the engine operates efficiently and with minimal mechanical loss 1.

Role of the 3424077 Connecting Rod Bearing in Truck Operation

The Cummins 3424077 Connecting Rod Bearing plays a specific role in the engine’s operation by supporting the connecting rod as it reciprocates with the piston. This bearing ensures that the connecting rod can move smoothly and consistently, which is vital for the engine’s overall performance. By maintaining a precise fit and low-friction surface, the bearing contributes to the engine’s efficiency and durability.

Key Features of the 3424077 Connecting Rod Bearing

The Cummins 3424077 Connecting Rod Bearing is characterized by several key features that enhance its performance and durability. These include a robust material composition designed to withstand high loads and temperatures, precision engineering for optimal fit, and a low-friction surface to minimize wear. Additionally, the bearing may incorporate advanced design characteristics such as oil grooves to ensure proper lubrication, further enhancing its reliability in commercial truck applications 2.

Benefits of Using the 3424077 Connecting Rod Bearing

Utilizing the Cummins 3424077 Connecting Rod Bearing offers several advantages. These include improved engine efficiency due to reduced friction, enhanced durability under high-stress conditions, and contribution to overall engine reliability. The bearing’s design and material properties help to extend engine life and maintain performance, making it a valuable component in commercial truck engines.

Installation and Maintenance Guidelines

Proper installation of the Cummins 3424077 Connecting Rod Bearing involves several steps to ensure optimal performance. It is important to clean the crankshaft journal and connecting rod surfaces thoroughly before installation. The bearing should be placed carefully to avoid damage, and proper torque specifications should be followed during assembly. Regular maintenance practices, such as monitoring oil quality and ensuring adequate lubrication, are recommended to prolong the bearing’s service life and maintain engine efficiency 3.

Troubleshooting Common Issues

Common problems associated with connecting rod bearings include wear, noise, or failure. These issues can often be identified through symptoms such as unusual engine sounds, decreased performance, or visible damage. Troubleshooting steps may involve inspecting the bearing surfaces for wear, checking lubrication systems for proper function, and assessing the crankshaft journal for any irregularities. Addressing these issues promptly can help prevent more severe engine damage and ensure continued reliable operation.

Cummins: A Brief Overview

Cummins Inc. is a well-established manufacturer with a strong reputation in the automotive and heavy-duty truck industry. The company is known for its commitment to producing high-quality components, including the 3424077 Connecting Rod Bearing. Cummins’ history of innovation and dedication to excellence ensures that their products meet the rigorous demands of commercial applications, providing reliable performance and durability for their customers.

Role of Part 3424077 Connecting Rod Bearing in Engine Systems

In the context of an engine assembly, the 3424077 Connecting Rod Bearing facilitates smooth and efficient operation by reducing friction between the connecting rod and the crankshaft journal. This bearing is integral to the piston’s reciprocating motion, which is converted into rotational motion by the crankshaft.

When the piston moves up and down within the cylinder, the connecting rod transfers this linear motion to the crankshaft. The Connecting Rod Bearing ensures that this transfer occurs with minimal resistance, thereby enhancing the engine’s overall efficiency and durability.

In engines equipped with prechamber bits, such as the QSV and D67 models, the Connecting Rod Bearing plays a similarly significant role. These engines rely on precise timing and smooth operation of all moving parts to achieve optimal combustion and power output. The bearing’s low-friction surface allows the connecting rod to pivot effortlessly around the crankshaft journal, contributing to the engine’s reliability and performance.

Additionally, in rod bearing (stud) sets, the 3424077 Connecting Rod Bearing is often used to maintain the alignment and integrity of the connecting rod. This is particularly important in high-performance or high-stress engine applications where the forces acting on the rod are substantial. The bearing helps distribute these forces evenly, preventing premature wear and potential failure of the connecting rod or crankshaft journal.

Conclusion

The Cummins 3424077 Connecting Rod Bearing is a critical component in commercial truck engines, designed to enhance engine performance, efficiency, and reliability. Its robust design, precision engineering, and low-friction properties make it an essential part for maintaining the smooth operation of the engine. Proper installation, regular maintenance, and prompt troubleshooting of common issues are key to maximizing the service life and performance of this Cummins part.

-

Lakshminarayanan, P. A., & Aghav, Y. V. (2010). Modelling Diesel Combustion. Springer Science.

↩ -

Ferrari, A., & Pizzo, P. (2022). Injection Technologies: Mixture Formation Strategies. SAE International.

↩ -

Zhan, Q., Eben, S., & Deng, L. K. (2018). Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.