This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

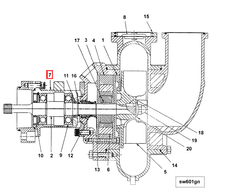

The Cummins 3393050 Bearing Housing is a component designed for heavy-duty trucks, playing a role in ensuring the smooth operation of various truck components. Its design and functionality are tailored to meet the demanding requirements of heavy-duty applications, contributing to the overall efficiency and reliability of the truck 1.

Basic Concepts of Bearing Housings

Bearing housings are integral components in machinery, providing a stable and secure environment for bearings. They contribute to the stability and efficiency of rotating components by protecting the bearings from external contaminants and ensuring proper alignment 2. Bearing housings also facilitate the distribution of loads and help in maintaining the integrity of the rotating parts.

Purpose of the 3393050 Bearing Housing

This part is specifically designed to support and align rotating parts within a truck’s drivetrain. It plays a role in maintaining the precise positioning of bearings, which is vital for the smooth operation of components such as shafts and gears. By ensuring proper alignment and support, the bearing housing contributes to the efficient transfer of power and reduces the likelihood of premature wear 3.

Key Features

This Cummins part boasts several key features that enhance its performance. It is constructed from durable materials that can withstand the rigors of heavy-duty use. The design includes precision-machined surfaces to ensure accurate bearing alignment. Additionally, it features integrated lubrication points to facilitate easy maintenance and prolong the lifespan of the bearings 4.

Benefits

The benefits of the 3393050 Bearing Housing include improved durability, reduced maintenance requirements, and enhanced operational efficiency. Its robust construction and precise design contribute to a longer service life, while the integrated lubrication points simplify maintenance routines. Furthermore, the housing’s role in maintaining bearing alignment leads to smoother operation and potentially improved fuel efficiency 5.

Installation Process

Proper installation of the 3393050 Bearing Housing involves several steps. Begin by ensuring the installation area is clean and free from debris. Use the appropriate tools to secure the housing in place, following the manufacturer’s guidelines for torque specifications. Align the housing with the rotating components to ensure optimal performance. Finally, check for proper lubrication and make any necessary adjustments 6.

Common Issues and Troubleshooting

Common issues with the 3393050 Bearing Housing may include wear and tear, misalignment, and lubrication problems. Regular inspections can help identify these issues early. Troubleshooting may involve realigning the housing, ensuring proper lubrication, or replacing worn components. Addressing these issues promptly can prevent more significant problems down the line 7.

Maintenance Tips

To ensure the longevity and optimal performance of the 3393050 Bearing Housing, regular maintenance is recommended. This includes periodic inspections to check for signs of wear or misalignment. Lubrication should be checked and replenished as needed, following the manufacturer’s guidelines. Keeping the housing clean and free from contaminants will also contribute to its longevity 8.

Role in Truck Performance

The 3393050 Bearing Housing contributes to overall truck performance by supporting the efficient operation of rotating components. Its role in maintaining bearing alignment and protecting the bearings from wear can lead to improved fuel efficiency and reliability. Additionally, by ensuring the smooth operation of the drivetrain, the housing can help in maintaining the truck’s load-carrying capacity 9.

Conclusion

In summary, the 3393050 Bearing Housing is a critical component in the operation of heavy-duty trucks, designed to support and align rotating parts within the drivetrain. Its robust construction, precise design, and integrated lubrication points contribute to improved durability, reduced maintenance requirements, and enhanced operational efficiency. Regular maintenance and prompt troubleshooting of common issues are essential to ensure the longevity and optimal performance of this part.

References

-

Sclar, D. (2008). Auto Repair for Dummies: 2nd Edition. For Dummies.

↩ -

Hilgers, M. (2023). Electrical Systems and Mechatronics, Second Edition. Springer Vieweg.

↩ -

ElGindy, M., & ElSayegh, Z. (2023). Road and Off-Road Vehicle Dynamics. Springer Nature.

↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for B6.2 CM2670 B156B, Bulletin Number 5579509.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for B6.2 CM2670 B156B, Bulletin Number 5579509.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for B6.2 CM2670 B156B, Bulletin Number 5579509.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for B6.2 CM2670 B156B, Bulletin Number 5579509.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for B6.2 CM2670 B156B, Bulletin Number 5579509.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.