This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3008022 Thrust Ball Bearing, manufactured by Cummins, is a specialized component designed for use in commercial trucks. Cummins, a well-established name in the automotive industry, is known for its high-quality engine and component manufacturing. This thrust ball bearing is integral to the efficient operation of trucks, particularly in managing axial loads within the engine system.

Basic Concepts of Thrust Ball Bearings

Thrust ball bearings are mechanical components designed to handle axial loads, which are forces that act parallel to the shaft axis. They consist of a set of ball bearings positioned between two races, one stationary and one rotating. When a load is applied, the balls roll between the races, minimizing friction and allowing smooth axial movement. These bearings are commonly used in various mechanical systems where axial load management is crucial, such as in automotive engines, turbines, and industrial machinery 1.

Purpose of the 3008022 Thrust Ball Bearing in Truck Operation

In the operation of a truck, the 3008022 Thrust Ball Bearing plays a significant role by managing axial loads within the engine system. This bearing is typically found in the crankshaft or other rotating assemblies where it helps to maintain proper alignment and reduce friction. By efficiently handling axial forces, it contributes to the smooth operation of the engine, enhancing overall performance and reliability 2.

Key Features

The 3008022 Thrust Ball Bearing boasts several key features that enhance its performance. It is constructed from high-quality materials, ensuring durability and resistance to wear. The design includes precision-machined races and high-grade steel balls, which contribute to its smooth operation and load-carrying capacity. Additionally, the bearing is engineered to operate under high-stress conditions, making it suitable for the demanding environment of commercial truck engines 3.

Benefits

The 3008022 Thrust Ball Bearing offers several benefits that contribute to its effectiveness in truck applications. Its design allows for improved efficiency by reducing friction, which in turn enhances the engine’s performance. The bearing’s durability ensures long-term reliability, reducing the need for frequent replacements. Furthermore, its ability to handle high axial loads makes it a valuable component in maintaining the integrity of the engine system.

Installation Considerations

When installing the 3008022 Thrust Ball Bearing, it is important to follow Cummins’ guidelines to ensure proper functionality. The installation process should begin with a thorough inspection of the bearing and the surrounding components to ensure they are free from damage or contamination. The bearing should be installed with precise alignment to prevent undue stress and ensure optimal performance. Lubrication is also a critical aspect of installation, as it helps to reduce friction and wear during operation.

Troubleshooting Common Issues

Common issues with thrust ball bearings can include noise, vibration, and premature wear. These problems often arise from improper installation, lack of lubrication, or excessive loads. To troubleshoot these issues, it is important to first inspect the bearing and its surroundings for any signs of damage or misalignment. Ensuring proper lubrication and alignment can often resolve these problems. If the bearing shows signs of significant wear, replacement may be necessary.

Maintenance Tips

Regular maintenance of the 3008022 Thrust Ball Bearing is crucial for ensuring its longevity and optimal performance. This includes periodic inspection for signs of wear or damage, as well as ensuring that the bearing is properly lubricated. Lubrication should be performed according to Cummins’ recommendations to prevent friction and heat buildup. Additionally, maintaining clean operating conditions can help to extend the life of the bearing by reducing the risk of contamination.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the rigorous demands of commercial applications. Cummins’ commitment to excellence is reflected in its high-quality components, such as the 3008022 Thrust Ball Bearing, which are engineered to deliver reliable performance in demanding environments.

Cummins Thrust Ball Bearing 3008022 in Engine Applications

The Cummins Thrust Ball Bearing part number 3008022 is a critical component in various engine configurations, ensuring smooth operation and longevity of the engine. This bearing is designed to handle axial loads, providing stability and reducing friction in the engine’s rotating assemblies.

K19 Engine Series

In the K19 engine series, the Thrust Ball Bearing 3008022 plays a pivotal role in maintaining the integrity of the crankshaft. This engine series is known for its robust design and high performance, often used in heavy-duty applications. The bearing’s precision engineering ensures that the crankshaft can rotate smoothly, minimizing wear and extending the engine’s operational life.

The integration of the Thrust Ball Bearing 3008022 in the K19 engine series is a testament to Cummins’ commitment to quality and reliability. This bearing is strategically placed to support the crankshaft’s axial movement, providing a stable platform for the engine’s operation. Its design allows for efficient load distribution, reducing the risk of mechanical failure and enhancing the engine’s overall performance.

By incorporating the Thrust Ball Bearing 3008022, Cummins ensures that the K19 engine series can handle the demanding conditions of heavy-duty applications, maintaining its efficiency and reliability over extended periods.

Role of Part 3008022 Thrust Ball Bearing in Engine Systems

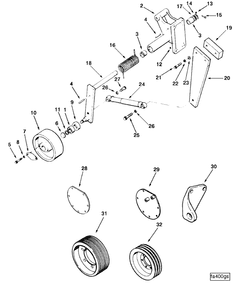

The part 3008022 Thrust Ball Bearing is instrumental in facilitating smooth operation and efficient performance within various engine components.

In the drive system, this bearing allows for minimal friction between moving parts, ensuring that power transmission from the engine to other components is seamless and efficient. It supports the axial loads that occur during operation, maintaining alignment and reducing wear on the drive components.

Within the fan system, the Thrust Ball Bearing plays a significant role in supporting the fan’s rotational axis. It accommodates the thrust loads generated as the fan operates, which is essential for maintaining consistent airflow and cooling efficiency. This bearing ensures that the fan can spin freely without excessive resistance, which is vital for optimal engine performance.

In the fan assembly idler, the bearing is used to manage the load and motion between the idler pulley and the fan belt. It allows for smooth belt movement and reduces the stress on the idler, prolonging the lifespan of the assembly and ensuring reliable operation.

For the fan drive arrangement, the Thrust Ball Bearing is key in handling the axial forces that arise from the fan’s operation. It ensures that the drive components remain properly aligned and function efficiently, which is important for the overall stability and performance of the engine system.

Conclusion

The 3008022 Thrust Ball Bearing by Cummins is a critical component in the efficient operation of commercial truck engines. Its design and features contribute to the smooth handling of axial loads, enhancing engine performance and reliability. Proper installation, maintenance, and troubleshooting are essential to ensure the longevity and optimal performance of this Cummins part.

-

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning.

↩ -

Rajamani, R. (2005). Vehicle Dynamics and Control. Springer.

↩ -

Reif, K. (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.