This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

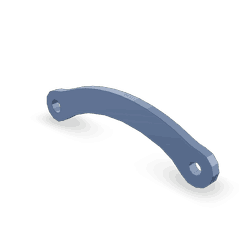

The 5448483 Alternator Brace is a component designed by Cummins to enhance the operation of heavy-duty trucks. This brace serves a specific function within the truck’s electrical system, contributing to the overall efficiency and reliability of the vehicle. Cummins, a well-established manufacturer in the industry, produces this part with a focus on quality and performance 1.

Basic Concepts of Alternator Braces

An alternator brace is a structural component that supports the alternator within a truck’s engine compartment. Its primary function is to provide additional stability to the alternator, which is important for maintaining consistent electrical output. The alternator brace interacts with the alternator and other components of the electrical system to ensure smooth operation and reduce vibrations that could affect performance 2.

Purpose of the 5448483 Alternator Brace

The 5448483 Alternator Brace plays a role in the operation of a truck by enhancing the stability and efficiency of the alternator. By securing the alternator more firmly in place, this brace helps to minimize movement and vibrations. This stability contributes to more consistent electrical output, which is vital for the reliable operation of the truck’s electrical systems 3.

Key Features

The 5448483 Alternator Brace is constructed from durable materials, ensuring it can withstand the rigors of heavy-duty truck operation. Its design includes specific elements that enhance its performance, such as precise mounting points that align perfectly with the alternator and engine components. Additionally, the brace may feature unique attributes like vibration dampening materials or a streamlined shape to reduce aerodynamic drag 4.

Benefits of Using the 5448483 Alternator Brace

Incorporating the 5448483 Alternator Brace into a truck’s electrical system offers several advantages. It contributes to improved alternator longevity by reducing wear and tear caused by vibrations. Enhanced electrical system reliability is another benefit, as the brace helps maintain consistent alternator output. Furthermore, the overall performance of the truck may see improvements due to the more stable electrical supply 5.

Installation Considerations

When installing the 5448483 Alternator Brace, it is important to follow guidelines and best practices to ensure proper integration with the truck’s electrical system. Preparatory steps may include inspecting the alternator and surrounding components for any signs of damage or wear. Tools required for installation might include standard wrenches and possibly a torque wrench to ensure bolts are tightened to the manufacturer’s specifications. Common pitfalls to avoid during installation include over-tightening bolts, which could damage threads, and ensuring all connections are secure to prevent future issues 6.

Troubleshooting and Maintenance

Identifying and resolving common issues related to the 5448483 Alternator Brace involves regular inspections for signs of wear or damage. Routine maintenance practices include checking the tightness of mounting bolts and ensuring that the brace remains securely attached to the alternator and engine components. Addressing any issues promptly can help maintain optimal performance and prevent more significant problems down the line 7.

Cummins: Manufacturer Overview

Cummins is a reputable manufacturer with a long-standing history in the industry. Known for its commitment to quality and innovation, Cummins produces a wide range of components for heavy-duty trucks. The company’s reputation is built on delivering reliable and high-performance parts that meet the demanding requirements of commercial vehicle operations 8.

Cummins Alternator Brace Part 5448483 Compatibility

The Cummins Alternator Brace part number 5448483 is designed to fit a variety of Cummins engines, ensuring a secure and stable mounting for the alternator. This part is important for maintaining the alternator’s position and preventing any unwanted movement that could lead to mechanical issues.

Compatible Engines

-

6B5.9 Series

- 6B5.9

-

B4.5 Series

- B4.5 CM2350 B129B

-

B5.6 Series

- B5.6 CM2670 B152B

-

B6.7 Series

- B6.7 CM2350 B135B

- B6.7 CM2670 B153B

- B6.7 G CMOH6.0 B125

-

F3.8 Series

- F3.8 CM2350 F120B

- F3.8 CM2620 F137B

-

F4.5 Series

- F4.5 CM2620 F139B

-

ISB/ISD Series

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

-

ISB Series

- ISB4.5 CM2350 B104

- ISB5.9 CM2880 B110

- ISB5.9 CM2880 B140

- ISB5.9 CM2880 B149

- ISB5.9G CM2180

- ISB6.7 CM2350 B101

- ISB6.7 G CM2180 B118

-

ISBE Series

- ISBE CM2150

- ISBE4 CM850

-

ISF Series

- ISF4.5 CM2220 F123

-

QSF Series

- QSF3.8 CM2350 F107

This alternator brace is engineered to provide a reliable fit across these diverse engine models, ensuring that the alternator remains securely in place, regardless of the engine type 9.

Understanding the Role of Part 5448483 Alternator Brace in Engine Systems

Part 5448483, the Alternator Brace, is an important component in the integration and stabilization of the alternator within various engine systems. This brace significantly enhances the structural integrity and operational efficiency of the alternator by providing additional support and mounting stability 10.

Integration with Alternator Mounting and Support Systems

The Alternator Brace works in conjunction with the alternator mounting and support systems to ensure that the alternator remains securely fastened to the engine. By reinforcing the connection points between the alternator and the engine block, the brace minimizes vibrations and potential movement that could otherwise lead to electrical inefficiencies or mechanical wear 11.

Enhancing Alternator Stability

In addition to its mounting role, the Alternator Brace contributes to the overall stability of the alternator. This is particularly important in high-performance or high-stress engine environments where the alternator is subjected to significant vibrations and thermal expansion. The brace helps maintain consistent electrical output by preventing the alternator from shifting or becoming misaligned 12.

Support for Alternator Functionality

The brace also plays a supportive role in maintaining the alternator’s functionality. By providing a rigid framework, it ensures that the alternator can operate within its optimal parameters. This is vital for consistent power generation, which is essential for the reliable operation of the vehicle’s electrical systems 13.

Contribution to Engine Longevity

By stabilizing the alternator and reducing unnecessary movement, the Alternator Brace indirectly contributes to the longevity of the engine. A well-supported alternator is less likely to suffer from premature wear or failure, which can lead to more extensive and costly repairs down the line 14.

Summary of Component Interaction

In summary, Part 5448483 Alternator Brace is a key component that interacts with the alternator mounting, alternator support, and the alternator itself to create a robust and reliable system. Its role in enhancing stability, reducing vibrations, and supporting consistent alternator functionality makes it an invaluable part of modern engine systems 15.

Conclusion

The 5448483 Alternator Brace is a critical component for enhancing the stability and efficiency of the alternator in heavy-duty trucks. By providing additional support and reducing vibrations, this Cummins part contributes to the reliable operation of the truck’s electrical systems. Proper installation and maintenance of the Alternator Brace are essential to ensure optimal performance and longevity of the alternator and engine.

-

Randall, Martynn. Haynes Manual on Diesel Engines. Haynes Publishing, 2015.

↩ -

Ribbens, William B. Understanding Automotive Electronics. Elsevier Science, 2003.

↩ -

Huzij, Robert, Spano, Angelo, Bennett, Sean. Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning, 2019.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4367450, QSK60 CM2350 K117.

↩ -

Randall, Martynn. Haynes Manual on Diesel Engines. Haynes Publishing, 2015.

↩ -

Ribbens, William B. Understanding Automotive Electronics. Elsevier Science, 2003.

↩ -

Huzij, Robert, Spano, Angelo, Bennett, Sean. Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning, 2019.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4367450, QSK60 CM2350 K117.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4367450, QSK60 CM2350 K117.

↩ -

Randall, Martynn. Haynes Manual on Diesel Engines. Haynes Publishing, 2015.

↩ -

Ribbens, William B. Understanding Automotive Electronics. Elsevier Science, 2003.

↩ -

Huzij, Robert, Spano, Angelo, Bennett, Sean. Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning, 2019.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4367450, QSK60 CM2350 K117.

↩ -

Randall, Martynn. Haynes Manual on Diesel Engines. Haynes Publishing, 2015.

↩ -

Ribbens, William B. Understanding Automotive Electronics. Elsevier Science, 2003.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.