This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

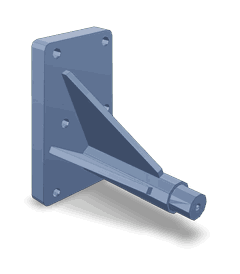

The Cummins 4001300 Alternator Bracket is a component designed to support the alternator in commercial trucks. Its purpose is to ensure the alternator is securely mounted and operates efficiently, contributing to the truck’s electrical system functionality. The significance of this bracket lies in its role in maintaining the alternator’s position and facilitating its operation within the truck’s engine compartment 1.

Basic Concepts of Alternator Brackets

An alternator bracket serves as a mounting structure for the alternator, which is a key component in a truck’s electrical system. The alternator generates electrical power to charge the battery and supply electricity to the truck’s electrical components while the engine is running. The bracket interfaces with the truck’s engine and frame, providing a stable platform for the alternator. This setup ensures that the alternator remains in the correct position and operates under the appropriate conditions for efficient power generation 2.

Purpose of the 4001300 Alternator Bracket

The 4001300 Alternator Bracket plays a role in the operation of a truck by supporting the alternator. It ensures that the alternator is held firmly in place, allowing it to spin at the correct speed and angle relative to the engine’s crankshaft. This support is vital for the alternator to generate electricity efficiently. Additionally, the bracket helps in dissipating heat generated by the alternator, contributing to its longevity and performance 3.

Key Features

The design and construction of the 4001300 Alternator Bracket incorporate several features that enhance its performance and durability. It is typically made from high-strength materials to withstand the vibrations and stresses encountered in a truck’s engine compartment. The bracket includes precise mounting points that align with the truck’s frame and the alternator, ensuring a secure fit. Unique attributes may include corrosion-resistant coatings or designs that facilitate easier installation and maintenance.

Benefits

The 4001300 Alternator Bracket offers several advantages. Its robust construction contributes to improved reliability, ensuring the alternator remains securely mounted under various operating conditions. The design of the bracket may also facilitate ease of installation, reducing the time and effort required for replacement or maintenance. Additionally, its compatibility with Cummins engines ensures that it meets the specific requirements and standards of these engines, enhancing overall system performance.

Installation Process

Installing the 4001300 Alternator Bracket involves several steps to ensure a secure fit. The process begins with preparing the engine compartment by removing the old bracket and any debris. The new bracket is then positioned according to the manufacturer’s guidelines, ensuring it aligns correctly with the mounting points on the truck’s frame. Tools required may include wrenches and possibly a torque wrench to secure the bracket in place. Following the manufacturer’s instructions for torque specifications is important to avoid over-tightening or under-tightening the fasteners.

Maintenance and Troubleshooting

Maintaining the 4001300 Alternator Bracket involves regular inspections to ensure it remains securely mounted and free from corrosion or damage. Common issues that may arise include loose fasteners or wear on the bracket itself. Troubleshooting steps may involve tightening fasteners to the manufacturer’s specifications or replacing the bracket if it shows signs of significant wear or damage. Regular maintenance helps in identifying potential issues before they lead to alternator failure or other electrical problems.

Manufacturer Overview - Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s product range includes engines, powertrains, and aftermarket parts designed to meet the demanding requirements of commercial vehicles. Cummins’ commitment to excellence and customer satisfaction has made it a preferred choice among truck manufacturers and operators worldwide.

Cummins Alternator Bracket 4001300 Compatibility with QSK Engines

The Cummins Alternator Bracket part number 4001300 is designed to be compatible with a range of Cummins QSK engines. Specifically, this bracket is engineered to fit seamlessly with the QSK45 CM500, QSK60 CM500, and QSK78 CM500 engines.

For the QSK45 CM500, QSK60 CM500, and QSK78 CM500 engines, the alternator bracket ensures a secure and reliable mounting of the alternator. This is crucial for maintaining the electrical system’s integrity and performance, as the alternator is responsible for charging the battery and powering the vehicle’s electrical components while the engine is running.

The bracket’s design accommodates the specific mounting points and alignment requirements of these engines, ensuring that the alternator operates efficiently and without undue stress on the mounting hardware. This compatibility is essential for maintaining the overall health and longevity of the engine’s electrical system.

Role of Part 4001300 Alternator Bracket in Engine Systems

The 4001300 Alternator Bracket is an integral component in the assembly and operation of various engine systems. It serves as a mounting point for the alternator, ensuring it is securely positioned and aligned with the engine’s drive system.

In engines equipped with a drive belt system, the Alternator Bracket allows the alternator to be properly tensioned against the belt. This ensures efficient power transfer from the engine to the alternator, which is essential for charging the battery and powering electrical components.

When considering engines with a fan assembly, the Alternator Bracket plays a role in maintaining the spatial arrangement of components. It ensures that the alternator does not interfere with the operation of the fan, which is responsible for cooling the engine. Proper placement and secure mounting provided by the bracket contribute to the overall efficiency and reliability of the engine’s cooling system.

Conclusion

The Cummins 4001300 Alternator Bracket is a critical component in the operation and maintenance of commercial truck electrical systems. Its robust design, compatibility with Cummins engines, and ease of installation make it a valuable part for ensuring the alternator’s efficient and reliable performance. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

-

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books, 2023.

↩ -

Kershaw, John F. SAE International’s Dictionary for Automotive Engineers. SAE International, 2023.

↩ -

Bennett, Sean, and Ian Andrew Norman. Heavy Duty Truck Systems Fifth Edition. Delmar Cengage Learning, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.