This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

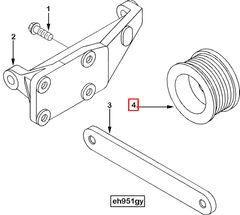

The Cummins 3919390 Alternator Pulley is a component designed for use in commercial trucks. Its purpose is to facilitate the operation of the alternator, which is responsible for generating electrical power to charge the battery and power the vehicle’s electrical systems. The significance of this part lies in its role in ensuring the alternator operates efficiently, thereby contributing to the overall performance and reliability of the truck.

Basic Concepts of Alternator Pulleys

An alternator pulley is a wheel attached to the alternator that interacts with the serpentine belt to drive the alternator. This interaction allows the alternator to spin and generate electricity. The alternator pulley must be precisely aligned and properly sized to ensure efficient power transfer and minimize wear on both the pulley and the belt. It works in conjunction with other engine components to maintain the electrical system’s functionality 1.

Purpose and Role of the 3919390 Alternator Pulley

This Cummins part is specifically designed to enhance the operation of the alternator in Cummins engines. It plays a role in the alternator’s function by ensuring smooth and consistent rotation, which is vital for the alternator to generate a stable electrical output. This, in turn, supports the engine’s performance by providing a reliable source of electrical power for various systems and components within the truck.

Key Features of the 3919390 Alternator Pulley

The 3919390 Alternator Pulley is constructed with high-quality materials to ensure durability and performance. Its design includes features such as a robust bearing system to reduce friction and wear, and a precision-machined surface to maintain the serpentine belt’s alignment and grip. These characteristics contribute to the pulley’s ability to withstand the demanding conditions of commercial truck operations 2.

Benefits of Using the 3919390 Alternator Pulley

Utilizing this part offers several advantages. It provides improved efficiency in power transmission from the engine to the alternator, which can lead to better overall electrical system performance. The pulley’s reliable construction ensures longevity, reducing the need for frequent replacements. Additionally, its compatibility with Cummins engines makes it a suitable choice for maintaining the integrity of the engine’s electrical system.

Installation and Compatibility

Proper installation of the 3919390 Alternator Pulley is important to ensure it functions correctly within the engine system. It is designed to meet specific requirements for alignment and tension to work effectively with the serpentine belt. The pulley is compatible with a range of Cummins engine models, making it a versatile component for various commercial truck applications.

Maintenance and Troubleshooting

Regular maintenance of the 3919390 Alternator Pulley is important to ensure its longevity and optimal performance. This includes checking for proper belt tension, inspecting for signs of wear or damage, and ensuring the pulley’s alignment is correct. Common issues may include belt slippage or pulley misalignment, which can often be addressed by adjusting tension or realigning the pulley.

Performance and Efficiency

The 3919390 Alternator Pulley contributes to the performance and efficiency of the truck’s engine system by ensuring the alternator operates within its designed parameters. This can lead to more consistent electrical output, which is important for the operation of the truck’s electrical systems and can contribute to overall engine efficiency.

Cummins: A Brief Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its wide range of diesel engines and components. The company has a reputation for producing high-quality, reliable parts that are trusted by professionals in the industry. Cummins components, including the 3919390 Alternator Pulley, are designed with precision and durability in mind, reflecting the brand’s commitment to excellence in the commercial vehicle sector 3.

Cummins Alternator Pulley 3919390 Compatibility

The Cummins Alternator Pulley part number 3919390 is designed to fit seamlessly with several engine models, ensuring optimal performance and reliability. This pulley is engineered to work with the following engines:

- 6C8.3

The 3919390 alternator pulley is specifically crafted to interface with the alternator system of the 6C8.3 engine. Its precision-engineered design ensures that it can handle the specific demands of this engine model, providing consistent power generation and efficient operation.

When installed, the 3919390 alternator pulley works in conjunction with the engine’s alternator to convert mechanical energy into electrical energy. This process is crucial for maintaining the battery charge and powering the vehicle’s electrical systems while the engine is running.

The compatibility of the 3919390 alternator pulley with the 6C8.3 engine is a testament to Cummins’ commitment to quality and precision engineering. This ensures that users can rely on this part for long-lasting performance and minimal maintenance needs.

Understanding the Integration of Part 3919390 Alternator Pulley in Engine Systems

The alternator pulley, specifically part 3919390, is an integral component in the efficient operation of an engine’s electrical system. Its primary role is to facilitate the mechanical connection between the engine’s crankshaft and the alternator. This connection is essential for the alternator to generate electrical power, which is then used to charge the battery and power the vehicle’s electrical systems.

Role in the Drive Belt System

The alternator pulley is part of the drive belt system, which includes the crankshaft pulley, water pump pulley, and other accessory pulleys. The drive belt wraps around these pulleys, transferring rotational force from the crankshaft to the alternator. This transfer of force is what spins the alternator’s rotor, enabling it to generate electricity.

Interaction with the Alternator

Once the alternator pulley is engaged by the drive belt, it spins the alternator’s rotor inside the stator. The rotor’s spinning creates a magnetic field that induces an electrical current in the stator windings. This current is then rectified and regulated to provide a stable DC voltage to charge the battery and power the vehicle’s electrical components.

Coordination with Engine Speed

The alternator pulley’s design allows it to maintain a consistent speed ratio between the engine and the alternator. This is important because the alternator needs to spin at a specific speed to generate the correct voltage. If the pulley were to allow the alternator to spin too fast or too slow, it could lead to overcharging or undercharging the battery, respectively.

Impact on Engine Performance

The efficient operation of the alternator pulley also has a direct impact on engine performance. A well-functioning alternator pulley ensures that the alternator does not place undue stress on the engine. This is because the pulley is designed to provide the optimal amount of resistance, allowing the alternator to draw just enough power from the engine to meet the electrical demands without causing excessive strain.

Maintenance and Efficiency

Regular maintenance of the alternator pulley, including checking for wear and proper alignment, is important for the longevity and efficiency of the engine’s electrical system. A misaligned or worn pulley can lead to increased friction, which not only reduces efficiency but can also lead to premature wear of the drive belt and other components.

Conclusion

In summary, the alternator pulley, part 3919390, plays a significant role in the seamless operation of the engine’s electrical system by ensuring the alternator receives the necessary mechanical force to generate electricity efficiently. Its integration into the drive belt system, interaction with the alternator, and coordination with engine speed are all critical factors that contribute to the overall performance and reliability of the vehicle’s electrical system.

-

Happian-Smith, Julian. An Introduction to Modern Vehicle Design. Butterworth-Heinemann, 2002.

↩ -

Wang, Yushu. Introduction to Engine Valvetrains. SAE International, 2007.

↩ -

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.