This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins Alternator Pulley 3255301 is a component designed for use in commercial trucks. It serves a specific function within the truck’s engine system, contributing to the operation of the alternator and, by extension, the truck’s electrical system. Understanding its role and significance can provide insights into the overall efficiency and reliability of the vehicle.

Basic Concepts of Alternator Pulleys

An alternator pulley is a mechanical component that facilitates the operation of the alternator within an engine system. It is connected to the alternator and interacts with the serpentine belt, which drives the alternator. The pulley’s rotation allows the alternator to generate electrical power, which is used to charge the battery and power the truck’s electrical systems 1.

Purpose and Role in Truck Operation

This Cummins part plays a role in the operation of a truck by ensuring the efficient functioning of the alternator. It is responsible for transferring rotational force from the engine to the alternator, enabling it to produce electrical energy. This energy is vital for maintaining the truck’s battery charge and powering electrical components, which are essential for the truck’s operation 2.

Key Features

The Alternator Pulley is characterized by its robust design and the materials used in its construction. It is engineered to withstand the demanding conditions of commercial truck operation. Features such as precision machining and high-quality materials contribute to its performance and durability, ensuring reliable operation under various driving conditions 3.

Benefits

Using this part can lead to improved efficiency and reliability in the truck’s electrical system. Its design and construction may result in enhanced performance, potentially leading to cost savings for fleet operators through reduced maintenance and repair needs.

Installation and Compatibility

Proper installation of the Alternator Pulley is important for ensuring optimal performance. It is designed to fit specific models of commercial trucks, and adherence to manufacturer guidelines during installation can help maintain the pulley’s efficiency and longevity.

Maintenance and Troubleshooting

Routine maintenance practices can help ensure the longevity and efficiency of the 3255301. Regular inspections for wear and proper tensioning of the serpentine belt are recommended. Troubleshooting common issues, such as unusual noises or a loose belt, can help identify and address potential problems early.

Performance and Efficiency

The 3255301 contributes to the overall performance and efficiency of the truck’s electrical system. Its role in the alternator’s operation can have measurable impacts on the electrical output and, indirectly, on fuel efficiency by ensuring the alternator operates within its designed parameters.

Cummins: A Brief Overview

Cummins Inc. is a company with a long history of expertise in diesel engines and components. It has established a reputation in the commercial truck industry for producing reliable and high-performance parts. The company’s commitment to quality and innovation is reflected in its wide range of products, including the 3255301 Alternator Pulley.

Compatibility of Cummins Alternator Pulley (Part 3255301)

The Cummins Alternator Pulley, identified by part number 3255301, is engineered to ensure efficient power transmission from the engine to the alternator, facilitating the charging of the vehicle’s battery and the operation of electrical systems.

M11 CELECT PLUS Engines

The M11 CELECT PLUS engines are part of Cummins’ renowned lineup, known for their robust performance and reliability. The Alternator Pulley 3255301 is specifically designed to fit these engines, ensuring optimal performance and longevity. This compatibility is crucial for maintaining the engine’s efficiency and preventing potential failures in the alternator system.

Grouping of Compatible Engines

While the primary focus here is on the M11 CELECT PLUS engines, it is important to note that the Cummins Alternator Pulley 3255301 is also compatible with a broader range of Cummins engines. This part is engineered to meet the stringent requirements of Cummins’ engine designs, ensuring a perfect fit and reliable operation across various models.

By choosing the Cummins Alternator Pulley 3255301, users can be confident in its compatibility and performance, knowing it is designed to work flawlessly with their specific engine needs.

Role of Part 3255301 Alternator Pulley in Engine Systems

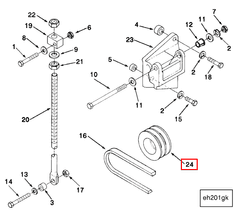

The alternator pulley, identified by part number 3255301, is integral to the efficient operation of the alternator within an engine system. This pulley is responsible for transmitting rotational force from the engine’s crankshaft to the alternator.

When the engine operates, the crankshaft’s rotation is transferred to the alternator pulley via a belt. This pulley ensures that the alternator rotates at the necessary speed to generate electrical power. The alternator, in turn, supplies this power to the vehicle’s electrical systems and recharges the battery.

Proper mounting of the alternator is essential for the pulley to function effectively. The alternator must be securely fastened to its designated location on the engine. This ensures that the pulley maintains the correct alignment with the crankshaft and other pulleys in the system. Misalignment can lead to inefficient power transmission, increased wear, and potential failure of the alternator or other components.

The alternator pulley’s design and material are optimized to handle the stresses and temperatures within the engine compartment. It must withstand continuous rotation and the tension of the drive belt, all while operating in a high-temperature environment.

Conclusion

In summary, the alternator pulley (part 3255301) plays a significant role in the engine system by ensuring the alternator receives the necessary rotational force to generate electricity. Its proper function is dependent on the correct mounting and alignment of the alternator, highlighting the interconnectedness of these components in maintaining the vehicle’s electrical system.

-

Miedema, S. A., & Lu, Z. (2010). The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema.

↩ -

Caines, A. J., Haycock, R. F., & Hillier, J. E. (2004). Automotive Lubricants Reference Book. SAE International.

↩ -

Hilgers, M. (2023). Electrical Systems and Mechatronics, Second Edition. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.