This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

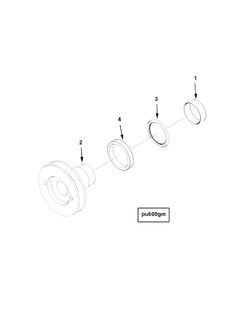

The Cummins 3246831 Alternator Pulley is a critical component designed for use in commercial trucks. Its primary function is to facilitate the operation of the alternator, which generates electrical power for the vehicle’s electrical systems. This part ensures that the alternator functions correctly within the engine system, contributing to the overall efficiency and reliability of the truck.

Basic Concepts of Alternator Pulleys

An alternator pulley is a component of the engine system that connects the alternator to the engine’s drive belt. Its function is to transfer rotational force from the engine to the alternator, enabling the alternator to generate electricity. This electrical power is essential for operating the truck’s electrical components, including lights, ignition systems, and various electronic devices 1.

Purpose and Function of the 3246831 Alternator Pulley

The 3246831 Alternator Pulley is specifically designed to interact with the alternator and the engine’s drive belt in commercial trucks. It ensures that the alternator rotates at the correct speed to generate sufficient electrical power. This pulley works in conjunction with other components to maintain the alternator’s optimal performance, thereby supporting the truck’s electrical system 2.

Key Features

The 3246831 Alternator Pulley is constructed with materials and dimensions tailored for durability and efficiency. It is made from high-quality materials to withstand the rigors of commercial truck operation. The pulley’s design includes precise dimensions to ensure proper fit and function within the engine system. Unique attributes such as reinforced construction and smooth surface finish enhance its performance and longevity 3.

Benefits of Using the 3246831 Alternator Pulley

Incorporating the 3246831 Alternator Pulley into truck engine systems offers several advantages. These include improved efficiency in power generation, enhanced reliability of the electrical system, and increased longevity of the alternator and related components. The pulley’s robust design contributes to the overall performance and durability of the truck’s engine system 4.

Installation Process

Proper installation of the 3246831 Alternator Pulley involves several steps. First, ensure the engine is turned off and cooled down. Use the appropriate tools to remove the old pulley and install the new one, making sure it is aligned correctly with the alternator and drive belt. Follow manufacturer guidelines for torque specifications and belt tension to ensure optimal performance.

Maintenance and Troubleshooting

Maintaining the 3246831 Alternator Pulley involves regular inspection for signs of wear or damage. Common issues include belt misalignment, pulley wear, and electrical system failures. Troubleshooting steps may involve checking belt tension, inspecting pulley alignment, and ensuring the alternator is functioning correctly. Regular maintenance helps ensure the pulley and alternator operate efficiently.

Compatibility and Applications

The 3246831 Alternator Pulley is designed for specific types of trucks and engine models. Ensuring proper fit and function is critical for the pulley’s performance. Compatibility information is available to help determine the correct application for this pulley, ensuring it integrates seamlessly with the truck’s engine system.

Cummins Corporation Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of engine and component products. With a history of innovation and quality, Cummins has established a strong reputation for producing reliable and high-performance parts. The company’s product range includes engines, filtration systems, and aftermarket parts, all designed to meet the demanding needs of commercial trucking.

Cummins Alternator Pulley 3246831 Compatibility

The Cummins Alternator Pulley part number 3246831 is designed to fit seamlessly with a range of Cummins engines, ensuring optimal performance and reliability. This alternator pulley is engineered to work with the K38 and K50 engine series, providing a crucial component in the engine’s electrical system.

K38 Engine Series

For the K38 engine series, the 3246831 alternator pulley is specifically tailored to meet the unique requirements of these engines. The design ensures a precise fit, allowing for efficient power transfer and minimal wear. This compatibility is crucial for maintaining the engine’s performance and longevity.

K50 Engine Series

Similarly, the K50 engine series benefits from the use of the 3246831 alternator pulley. This part is engineered to integrate smoothly with the K50 engines, ensuring that the alternator operates at peak efficiency. The precise fitment of the pulley is essential for the smooth operation of the engine’s electrical system, contributing to overall engine reliability and performance.

By ensuring that the 3246831 alternator pulley is compatible with both the K38 and K50 engine series, Cummins maintains a high standard of quality and performance across its engine lineup. This compatibility is a testament to Cummins’ commitment to providing reliable and efficient engine components.

Role of Part 3246831 Alternator Pulley in Engine Systems

The Part 3246831 Alternator Pulley is an integral component in the efficient operation of engine systems, specifically within the accessory drive system. This pulley is designed to work in conjunction with the alternator, ensuring that it operates at the optimal speed to generate the necessary electrical power for the vehicle’s electrical systems.

Integration with Accessory Drive System

In the accessory drive system, the alternator pulley is connected to the engine’s crankshaft via a belt. This setup allows the pulley to transfer rotational energy from the engine to the alternator. As the engine runs, the crankshaft’s rotation is transmitted through the belt to the alternator pulley, which in turn drives the alternator. This mechanical linkage ensures that the alternator spins at a consistent speed, enabling it to produce a stable electrical output.

Interaction with Other Components

The alternator pulley also interacts with other components within the accessory drive system. For instance, it is often part of a multi-pulley setup that includes components like the water pump pulley, power steering pulley, and air conditioning compressor pulley. Each of these pulleys is connected by a common belt or multiple belts, depending on the engine’s design. The alternator pulley must be precisely aligned and tensioned to ensure smooth operation and prevent belt slippage, which could lead to inefficient power transmission and potential damage to the alternator or other accessories.

Efficiency and Performance

The design of the alternator pulley is optimized to maintain efficiency and performance. It is engineered to minimize friction and wear, ensuring that the energy transfer from the engine to the alternator is as efficient as possible. This efficiency is vital for the overall performance of the engine system, as it directly impacts the electrical power available for the vehicle’s systems, including lighting, ignition, and various electronic controls.

Maintenance and Reliability

Regular maintenance of the alternator pulley is essential for the reliability of the engine system. Inspecting the pulley for signs of wear, ensuring proper belt tension, and aligning it correctly with other pulleys are key practices that help maintain the efficiency and longevity of the accessory drive system.

Conclusion

The 3246831 Alternator Pulley plays a significant role in the accessory drive system by ensuring the alternator operates at the correct speed, thereby maintaining the electrical supply needed for the vehicle’s operation. Its integration with other pulleys and components within the system highlights its importance in the overall functionality and performance of the engine.

-

Department of Energy Fundamentals Handbook, Department of Energy, 2015

↩ -

Automotive Systems Principles and Practice, G.K. Awari, V.S. Kumbhar, and R.B. Tirpude, CRC Press, 2011

↩ -

Pistons and Engine Testing, Wolf-Henning Schneider, Springer Nature, 2016

↩ -

Handbook of Diesel Engines, Klaus Mollenhauer and Helmut Tschoeke, Springer, 2010

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.