This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

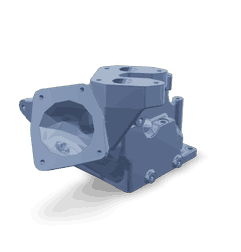

The Cummins 5298352 Air Intake Connection is a component designed for use in commercial trucks. It plays a role in the operation of these vehicles by facilitating the intake of air into the engine. This part is integral to the air induction system, ensuring that the engine receives the necessary airflow for optimal performance.

Basic Concepts of Air Intake Connection

Air intake connections in diesel engines are designed to channel air from the outside environment into the engine’s combustion chambers. This process is fundamental to the engine’s operation, as air is one of the primary components required for combustion. The efficiency and design of the air intake connection can influence engine performance, fuel efficiency, and emissions. By ensuring a steady and clean supply of air, these connections contribute to the overall effectiveness of the engine 1.

Purpose of the 5298352 Air Intake Connection

The 5298352 Air Intake Connection is specifically engineered to connect various components within the air induction system of a truck. Its role involves directing air flow from the air filter to the turbocharger or directly into the engine, depending on the truck’s configuration. This connection ensures that the engine receives a consistent supply of air, which is crucial for combustion and, consequently, for the truck’s performance.

Key Features

The 5298352 Air Intake Connection is characterized by its robust design and the materials used in its construction. It is typically made from durable materials that can withstand the high temperatures and pressures within the engine compartment. The connection is designed to be resistant to wear and corrosion, ensuring longevity and reliability. Additionally, it may feature specific fittings or adapters that allow for easy integration with other components of the air induction system.

Benefits

The use of the 5298352 Air Intake Connection offers several advantages. It contributes to improved engine performance by ensuring a steady and unrestricted flow of air into the engine. This can lead to better fuel efficiency and reduced emissions. The connection’s durable construction also enhances the reliability of the air induction system, reducing the likelihood of leaks or failures that could affect engine performance 2.

Installation Process

Installing the 5298352 Air Intake Connection requires careful attention to ensure a secure and proper fit. The process involves disconnecting the old connection, if present, and attaching the new one in its place. Tools such as wrenches and possibly a torque wrench may be required to ensure that all connections are tightened to the manufacturer’s specifications. It is important to follow the manufacturer’s instructions closely to avoid damaging the connection or other components.

Maintenance Tips

To ensure the optimal performance and longevity of the 5298352 Air Intake Connection, regular maintenance is recommended. This includes periodic inspections for signs of wear, corrosion, or damage. Cleaning the connection and its surrounding components can also help prevent the accumulation of dirt or debris that could obstruct airflow. Following the manufacturer’s maintenance schedule will help maintain the efficiency and reliability of the air induction system 3.

Troubleshooting Common Issues

Common issues with the 5298352 Air Intake Connection may include leaks or blockages that can affect engine performance. If a leak is suspected, inspecting the connection for signs of damage or loose fittings can help identify the source of the problem. Blockages may require cleaning or, in some cases, replacement of the connection. Addressing these issues promptly can help maintain engine efficiency and prevent more serious problems.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines, known for its high-quality products and innovative solutions in the commercial truck industry. With a history spanning over a century, Cummins has established a reputation for reliability, performance, and technological advancement. The company offers a wide range of products, including engines, filtration systems, and aftermarket parts, designed to meet the demanding requirements of commercial transportation.

Cummins Air Intake Connection Part 5298352

The Cummins Air Intake Connection part 5298352 is a component designed to ensure efficient air flow into the engine. This part is engineered to fit seamlessly with several Cummins engine models, enhancing the overall performance and reliability of these engines.

ISB6.7

The ISB6.7 engine benefits from the precise fit and functionality of the part 5298352. This part ensures that the air intake system operates smoothly, contributing to the engine’s robust power output and fuel efficiency.

CM2350

In the CM2350 engine, the part 5298352 plays a role in maintaining the integrity of the air intake system. Its design allows for optimal air flow, which is essential for the engine’s performance and longevity.

B101

For the B101 engine, the part 5298352 is engineered to provide a secure and efficient connection in the air intake system. This ensures that the engine receives the necessary air for combustion, thereby supporting its operational efficiency and reliability.

Grouped Engines

The part 5298352 is compatible with the ISB6.7, CM2350, and B101 engines, making it a versatile component for various Cummins engine models. Its design ensures that it fits well with these engines, providing a reliable air intake connection that supports the engine’s performance and durability.

Role of Part 5298352 Air Intake Connection in Engine Systems

The part 5298352 Air Intake Connection is a component in the air intake system of various engine setups. Its primary function is to facilitate a secure and efficient connection between the air intake and other components within the engine system.

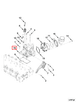

Integration with Key Components

-

Air Filter Housing: The Air Intake Connection interfaces directly with the air filter housing. This connection ensures that the air entering the engine is clean and free from contaminants, which is vital for maintaining engine performance and longevity.

-

Throttle Body: Another significant connection is made with the throttle body. This linkage allows for the precise control of airflow into the engine, which is necessary for optimal combustion and power output.

-

Intake Manifold: The Air Intake Connection also plays a role in linking to the intake manifold. This ensures that the air, now mixed with fuel, is evenly distributed to all cylinders, promoting consistent engine operation.

-

Mass Air Flow (MAF) Sensor: In systems equipped with a MAF sensor, the Air Intake Connection provides a pathway for the sensor to accurately measure the volume and density of the air entering the engine. This data is essential for the engine control unit (ECU) to make real-time adjustments to fuel delivery.

-

Intercooler (in Turbocharged Engines): For turbocharged engines, the Air Intake Connection may also interface with the intercooler. This setup helps in cooling the compressed air before it enters the engine, enhancing efficiency and power.

-

Air Bypass Valve: In some engine configurations, the Air Intake Connection may include provisions for an air bypass valve. This valve helps manage airflow during deceleration, improving engine responsiveness and reducing emissions.

Functional Impact

The effective integration of the Air Intake Connection with these components ensures that the engine receives a consistent and measured supply of air. This not only enhances performance but also contributes to the overall efficiency and reliability of the engine system.

Conclusion

The Cummins 5298352 Air Intake Connection is a vital component in the air induction system of commercial trucks. Its robust design, durable construction, and precise integration with key engine components ensure optimal engine performance, fuel efficiency, and reliability. Regular maintenance and prompt troubleshooting of common issues are essential to maintain the efficiency and longevity of this part.

-

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩ -

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩ -

Cummins Inc. (n.d.). G5.9, G855, GTA855 and G8.3 CM558/CM2358 Electronic Control System. Troubleshooting and Repair Manual. Bulletin Number 4021702.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.