This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

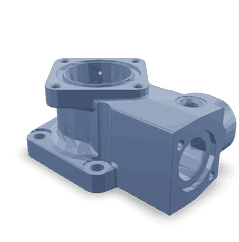

The Cummins 3938871 Air Fuel Mixer is designed to enhance the efficiency and performance of commercial truck engines by optimizing the air-fuel mixture entering the combustion chamber. This component ensures smooth engine operation, efficiency, and reduced emissions.

Basic Concepts of Air Fuel Mixers

An air fuel mixer combines air and fuel in the correct proportions before the mixture enters the engine’s combustion chamber. This process is fundamental to the engine’s operation, affecting power output, fuel consumption, and emissions. Maintaining the optimal air-fuel ratio is essential for achieving the best possible engine performance and efficiency 1.

Purpose of the Cummins 3938871 Air Fuel Mixer

The Cummins 3938871 Air Fuel Mixer optimizes the air-fuel mixture for combustion, ensuring the engine operates at peak efficiency. This optimization provides necessary power while minimizing fuel consumption and emissions. By precisely controlling the air-fuel ratio, the mixer contributes to the overall performance and reliability of the engine 2.

Key Features

The Cummins 3938871 Air Fuel Mixer incorporates several key features that enhance its performance and durability. These include a robust design, high-quality materials, and technological advancements that improve the accuracy of air-fuel mixture control. These features collectively contribute to the mixer’s effectiveness in optimizing engine performance.

Benefits

The Cummins 3938871 Air Fuel Mixer offers several benefits, including improved engine performance, enhanced fuel efficiency, and reduced emissions. By ensuring the optimal air-fuel mixture, the mixer helps the engine operate more efficiently, leading to better power output and lower fuel consumption. Additionally, the precise control of the air-fuel ratio contributes to lower emissions, helping trucks comply with environmental regulations 3.

Installation Process

Installing the Cummins 3938871 Air Fuel Mixer involves several steps to ensure proper integration with the engine system. The process begins with preparing the engine compartment and disconnecting any necessary components. The mixer is then positioned and secured in place, followed by reconnecting any disconnected parts. Tools required for installation may include wrenches, screwdrivers, and possibly a torque wrench to ensure proper tightening of fasteners.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3938871 Air Fuel Mixer, regular maintenance is recommended. This includes periodic checks for any signs of wear or damage, cleaning the mixer to remove any buildup that could affect its operation, and ensuring all connections are secure. Following the manufacturer’s maintenance schedule and guidelines will help maintain the mixer’s efficiency and reliability.

Troubleshooting Common Issues

Common problems associated with the Cummins 3938871 Air Fuel Mixer may include issues with the air-fuel mixture, leading to poor engine performance or increased emissions. Troubleshooting steps may involve checking for leaks in the air or fuel lines, ensuring the mixer is properly installed and secured, and verifying that the air-fuel ratio is within the specified range. Addressing these issues promptly can help maintain the engine’s performance and efficiency.

Impact on Engine Performance

The Cummins 3938871 Air Fuel Mixer influences engine performance by optimizing the air-fuel mixture, which affects power output, fuel consumption, and overall efficiency. A well-mixed air-fuel ratio ensures that the engine operates at its best, providing the necessary power while minimizing fuel use and emissions. This optimization contributes to the engine’s reliability and longevity.

Environmental Considerations

Using the Cummins 3938871 Air Fuel Mixer has a positive environmental impact by reducing emissions. The precise control of the air-fuel mixture helps minimize the release of harmful pollutants, contributing to cleaner air and compliance with environmental regulations. This component plays a role in the efforts to reduce the environmental footprint of commercial trucks.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a history of innovation and a commitment to sustainability, Cummins serves customers in approximately 190 countries and territories, providing reliable and efficient power solutions for various applications, including commercial trucks.

Cummins Air Fuel Mixer Part 3938871 Compatibility

The Cummins Air Fuel Mixer part number 3938871 is designed to be compatible with a range of engine models. This part ensures the proper mixing of air and fuel, which is essential for efficient combustion and optimal engine performance.

B5.9 G and B5.9 GAS PLUS CM556

The Air Fuel Mixer part 3938871 is specifically engineered to fit the B5.9 G and B5.9 GAS PLUS CM556 engines. These engines are known for their reliability and performance in various applications. The mixer ensures that the air and fuel are combined in the correct proportions, enhancing the engine’s efficiency and reducing emissions.

G5.9

Similarly, the G5.9 engine also benefits from the use of the Cummins Air Fuel Mixer part number 3938871. This part is designed to integrate seamlessly with the G5.9 engine, providing the necessary components for effective air and fuel mixing. This compatibility ensures that the engine operates smoothly and maintains its performance over time.

By ensuring that the Air Fuel Mixer part 3938871 is compatible with these engines, Cummins guarantees that users can maintain their engines’ efficiency and longevity. This part is a critical component in the engine’s overall functionality, and its proper installation is essential for optimal performance.

Role of Part 3938871 Air Fuel Mixer in Engine Systems

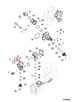

The Air Fuel Mixer, identified by part number 3938871, is integral to the efficient operation of engine systems, particularly when integrated with the Module and Fuel Control components.

Integration with the Module

When the Air Fuel Mixer is paired with the Module, it enhances the precision of air and fuel mixture delivery. The Module, which typically houses electronic controls and sensors, relies on consistent and accurate air-fuel ratios to optimize engine performance. The Air Fuel Mixer ensures that the air and fuel are thoroughly mixed before entering the combustion chamber, which is essential for the Module to maintain optimal ignition timing and fuel delivery parameters. This synergy between the Mixer and the Module results in improved engine efficiency and reduced emissions.

Collaboration with the Fuel Control

The Fuel Control component is responsible for regulating the amount of fuel that is injected into the engine. The Air Fuel Mixer works in tandem with the Fuel Control to ensure that the fuel is properly atomized and mixed with the incoming air. This precise mixture is vital for the Fuel Control to operate within its designed parameters, ensuring that the engine receives the correct fuel-air ratio for combustion. The Mixer’s ability to consistently provide a well-mixed charge allows the Fuel Control to make fine adjustments to fuel delivery, enhancing overall engine performance and fuel economy.

Conclusion

In summary, the Cummins 3938871 Air Fuel Mixer plays a significant role in the engine system by ensuring that the air and fuel are optimally mixed, which is essential for the Module and Fuel Control to function effectively. This integration leads to enhanced engine performance, efficiency, and emissions control.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.