This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5302588 Air-Fuel Throttle Valve is a component designed to regulate the air-fuel mixture in commercial truck engines. Its purpose is to ensure that the engine operates efficiently by maintaining the optimal air-fuel ratio necessary for combustion. This valve plays a role in the overall performance and fuel efficiency of the truck, contributing to smoother operation and reduced emissions 1.

Basic Concepts of Air-Fuel Throttle Valves

An Air-Fuel Throttle Valve is a device that controls the amount of air and fuel entering the engine’s combustion chamber. By adjusting the air-fuel mixture, the valve helps to optimize combustion, which in turn affects engine performance, fuel consumption, and emissions. The valve operates by responding to signals from the engine control unit (ECU), which monitors various parameters such as engine load, speed, and temperature to determine the ideal air-fuel ratio 2.

Role of the 5302588 Air-Fuel Throttle Valve in Truck Operation

The 5302588 Air-Fuel Throttle Valve specifically contributes to the operation of a truck by precisely controlling the air-fuel mixture. This regulation ensures that the engine performs efficiently under varying conditions, whether the truck is idling, cruising, or under heavy load. The valve’s ability to maintain an optimal air-fuel ratio enhances engine performance, improves fuel efficiency, and reduces the likelihood of engine knocking or other performance issues 3.

Key Features of the 5302588 Air-Fuel Throttle Valve

The 5302588 Air-Fuel Throttle Valve is characterized by its robust design and high-quality materials, which ensure durability and reliability in demanding commercial truck applications. The valve features precise engineering to allow for accurate control of the air-fuel mixture. Additionally, it is designed to integrate seamlessly with Cummins engines, ensuring compatibility and optimal performance. Unique characteristics of this valve include its resistance to wear and corrosion, contributing to its longevity and reliability.

Benefits of Using the 5302588 Air-Fuel Throttle Valve

Utilizing the 5302588 Air-Fuel Throttle Valve offers several benefits. It contributes to improved engine performance by ensuring that the air-fuel mixture is always optimal, which can lead to increased power output and smoother operation. Enhanced fuel efficiency is another advantage, as the precise control of the air-fuel ratio reduces fuel consumption. Additionally, the valve’s reliable operation contributes to increased engine reliability and reduced maintenance requirements.

Installation and Integration

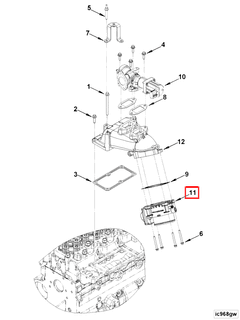

Installing and integrating the 5302588 Air-Fuel Throttle Valve into a truck’s engine system requires careful consideration to ensure proper function. It is important to follow manufacturer guidelines for installation, which may include specific torque settings for mounting the valve and ensuring that all connections are secure. In some cases, modifications or adjustments to the engine system may be necessary to accommodate the valve, particularly in ensuring compatibility with the ECU.

Troubleshooting Common Issues

Common issues with the 5302588 Air-Fuel Throttle Valve may include malfunctions due to wear, electrical faults, or contamination. Troubleshooting steps may involve checking for proper electrical connections, inspecting the valve for signs of wear or damage, and ensuring that the air and fuel passages are clean and unobstructed. Diagnostic tools may be used to monitor the valve’s operation and identify any irregularities in the air-fuel mixture.

Maintenance and Care

To ensure optimal performance and longevity of the 5302588 Air-Fuel Throttle Valve, regular maintenance and care are recommended. This includes periodic inspection for signs of wear or damage, cleaning the valve to remove any contaminants that may affect its operation, and replacing worn components as necessary. Adhering to the manufacturer’s maintenance schedule will help to prevent issues and ensure that the valve continues to operate efficiently.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins has established a reputation for producing high-quality, reliable components that meet the demanding requirements of commercial and industrial applications. The company’s commitment to innovation, quality, and customer satisfaction has made it a trusted name in the automotive and heavy-duty truck industries.

Cummins Air-Fuel Throttle Valve Part 5302588 Compatibility

The Cummins Air-Fuel Throttle Valve part number 5302588 is designed to integrate seamlessly with various engine models, ensuring optimal performance and efficiency. This part is engineered to fit within the engine systems of several key engine series, providing a reliable solution for maintaining the air-fuel ratio and overall engine operation.

ISB (Chrysler)

The ISB engine series, developed by Chrysler, incorporates the Cummins Air-Fuel Throttle Valve part 5302588 as a critical component. This valve is integral to the engine’s air intake system, regulating the airflow into the combustion chamber. By precisely controlling the air-fuel mixture, it enhances the engine’s performance, ensuring that it operates within the optimal parameters for power and efficiency. The integration of this part into the ISB engine series underscores its importance in maintaining the engine’s reliability and longevity.

Role of Part 5302588 Air-Fuel Throttle Valve in Engine Systems

The Part 5302588 Air-Fuel Throttle Valve is an integral component in the orchestration of air and fuel mixture within the engine system. Its primary function is to regulate the airflow into the engine, which directly influences the air-fuel ratio. This regulation is essential for optimal engine performance, fuel efficiency, and emissions control.

Interaction with Air Intake Connection

When considering the air intake connection, the Air-Fuel Throttle Valve plays a significant role. It is positioned downstream of the air intake connection, where it modulates the volume of air entering the engine. The valve opens and closes in response to signals from the engine control unit (ECU), adjusting the airflow to match the engine’s demand for power. This dynamic adjustment ensures that the engine receives the precise amount of air needed for combustion, which is particularly important during varying driving conditions such as acceleration, cruising, or idling.

The valve’s operation is synchronized with the air intake connection to maintain a consistent and efficient air supply. The air intake connection delivers ambient air into the intake manifold, where the throttle valve then controls the flow into the cylinders. This seamless integration allows for a responsive and efficient engine operation, enhancing overall vehicle performance.

Conclusion

The Cummins 5302588 Air-Fuel Throttle Valve is a critical component in ensuring the efficient operation of commercial truck engines. By precisely regulating the air-fuel mixture, this valve enhances engine performance, improves fuel efficiency, and reduces emissions. Its robust design, compatibility with Cummins engines, and ease of integration make it a reliable choice for maintaining optimal engine operation. Regular maintenance and proper installation are key to maximizing the benefits of this valve, ensuring long-term reliability and performance.

-

Duffy, Owen C., and Gus Wright. Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning, 2016.

↩ -

ElSayed, Mohamed PE. Fundamentals of Integrated Vehicle Realization. SAE International, 2017.

↩ -

Rendle, Steve, and Martynn Randall. Haynes Diesel Engine Systems and Data Book. Haynes Publishing, 2000.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.