This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

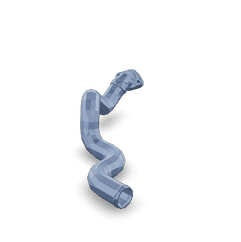

The Cummins 5283889 Air Transfer Tube is a component designed for use in commercial trucks. It serves a specific function within the truck’s air system, contributing to the overall efficiency and reliability of air-dependent operations. Understanding its purpose and role is fundamental for maintaining and optimizing truck performance.

Basic Concepts of Air Transfer Tubes

An Air Transfer Tube is a conduit that facilitates the movement of compressed air within a truck’s air system. It is integral to the operation of various air-dependent systems, including the air brake system. The tube ensures that air flows efficiently from the compressor to the storage tanks and other components that require pressurized air to function. The efficiency of this air flow is paramount for the proper operation of these systems, highlighting the importance of components like the Cummins 5283889 in maintaining system integrity 1.

Purpose of the Cummins 5283889 Air Transfer Tube

The Cummins 5283889 Air Transfer Tube plays a role in the air brake system and other air-dependent systems by providing a pathway for compressed air. It ensures that air is delivered under the correct pressure and volume to the necessary components, facilitating smooth and reliable operation of the truck’s braking system and other air-actuated functions. Its design and placement within the system are critical for maintaining the desired air pressure and flow, which are essential for safety and performance 2.

Key Features

The Cummins 5283889 Air Transfer Tube is constructed from materials that offer durability and resistance to the pressures and temperatures encountered within a truck’s air system. Its design includes features that enhance both durability and efficiency, such as reinforced connections and a streamlined shape to minimize air resistance. These attributes contribute to the tube’s longevity and reliable performance, setting it apart from other air transfer tubes on the market.

Benefits

Utilizing the Cummins 5283889 Air Transfer Tube can lead to improved air system performance, as it is engineered to maintain efficient air flow and pressure. This can result in increased reliability of air-dependent systems, potentially leading to cost savings over time through reduced maintenance needs and enhanced system longevity. The tube’s design and construction also contribute to its durability, further supporting its role in maintaining system efficiency.

Installation Considerations

Proper installation of the Cummins 5283889 Air Transfer Tube is vital for ensuring its effective operation within the truck’s air system. This process may require specific tools and adherence to manufacturer guidelines to ensure a secure and efficient fit. Attention to detail during installation can prevent issues such as air leaks or inefficient air flow, which could compromise the performance of air-dependent systems.

Troubleshooting and Maintenance

Regular maintenance and inspection of the Cummins 5283889 Air Transfer Tube can help identify potential issues before they lead to system failures. Common troubleshooting steps include checking for signs of wear or damage, ensuring connections are secure, and verifying that air flow and pressure are within specified parameters. Addressing these aspects can prolong the tube’s lifespan and maintain the efficiency of the air system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves commercial truck markets with a wide range of products designed to enhance performance, efficiency, and reliability. The company’s commitment to advancing technology and meeting the needs of its customers underscores its position as a leader in the industry.

Compatibility with Cummins Engines

The Air Transfer Tube part number 5283889, manufactured by Cummins, is designed to fit seamlessly with several of their engine models. Specifically, this part is compatible with the ISB6.7 CM2250 and ISB6.7 CM2350 B101 engines.

For the ISB6.7 CM2250 engine, the Air Transfer Tube plays a role in maintaining the efficiency of the air intake system. It ensures that the air flow is directed correctly, enhancing the engine’s performance and reliability.

Similarly, in the ISB6.7 CM2350 B101 engine, the Air Transfer Tube is engineered to integrate smoothly with the existing components. This integration is vital for the proper functioning of the engine, as it helps in maintaining the integrity of the air supply system.

Both engines benefit from the precise fit and high-quality construction of the Air Transfer Tube, ensuring that the air transfer process is efficient and reliable. This part is a component in the overall design of these engines, contributing to their durability and performance.

Role of Part 5283889 Air Transfer Tube in Engine Systems

The part 5283889 Air Transfer Tube is an integral component in the efficient operation of various engine systems. It serves as a conduit for the movement of air within the engine, facilitating the transfer of air between different components to ensure optimal performance.

Integration with Plumbing Systems

In engine systems, the Air Transfer Tube is often connected to the plumbing network. This network includes various hoses and pipes that manage the flow of fluids and gases. The tube’s role here is to direct air to where it is needed, whether it’s for cooling purposes, combustion enhancement, or other functions. The precise routing of air through this tube helps maintain the correct pressure and flow rates within the plumbing system, which is essential for the engine’s overall efficiency.

Contribution to Exhaust Recirculation Air Systems

The Air Transfer Tube also plays a significant role in Exhaust Recirculation (EGR) systems. In these systems, a portion of the exhaust gas is recirculated back into the intake manifold to reduce nitrogen oxides (NOx) emissions. The tube ensures that the recirculated exhaust gas is properly mixed with the incoming air, promoting a more complete combustion process and reducing harmful emissions. This integration helps the engine meet environmental regulations while maintaining performance standards.

Enhancing Combustion Efficiency

By facilitating the transfer of air to the combustion chamber, the Air Transfer Tube contributes to more efficient fuel combustion. Proper air-fuel mixture is vital for maximizing engine power output and minimizing fuel consumption. The tube ensures that the necessary amount of air reaches the combustion chamber at the right time, supporting a consistent and efficient burn.

Supporting Turbocharger and Supercharger Systems

In turbocharged and supercharged engines, the Air Transfer Tube is often used to route air from the compressor to the intake manifold. This ensures that the pressurized air is delivered efficiently to the engine, enhancing its performance. The tube’s design and placement are critical in maintaining the integrity of the air flow, which is essential for the effective operation of forced induction systems.

Role in Air Intake Systems

The Air Transfer Tube is also a key component in air intake systems. It connects the air filter to the throttle body or intake manifold, ensuring that clean, filtered air is delivered to the engine. This is important for maintaining engine health and performance, as contaminants in the air can cause wear and damage to engine components.

Conclusion

In summary, the Cummins 5283889 Air Transfer Tube is a versatile and essential component in various engine systems. Its role in directing and managing the flow of air contributes to the efficiency, performance, and environmental compliance of modern engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.