This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

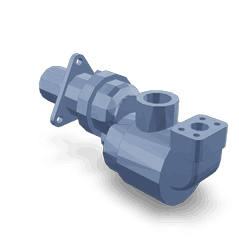

The Cummins 4978612 Air Starting Motor is a specialized component designed to facilitate the starting process of heavy-duty trucks. Its purpose is to provide the initial rotational force needed to start the engine using compressed air, ensuring efficient and reliable operation. This motor is significant in the context of heavy-duty truck operation, as it contributes to the overall performance and reliability of the vehicle 1.

Basic Concepts of Air Starting Motors

Air starting motors operate on the principle of using compressed air to initiate engine rotation. This process involves several key components, including the air reservoir, air compressor, and the air starting motor itself. When the starting sequence is initiated, compressed air is released into the motor, causing the pistons to move and rotate the engine. This mechanism is particularly useful in heavy-duty applications where electric starters may not provide sufficient power 2.

Role of the 4978612 Air Starting Motor in Truck Operation

The 4978612 Air Starting Motor plays a specific role in the starting process of heavy-duty trucks. It interacts with other engine components such as the flywheel, crankshaft, and pistons. When activated, the motor uses compressed air to turn the crankshaft, which in turn rotates the flywheel and initiates the combustion process. This interaction ensures a smooth and efficient start, reducing the strain on the engine and other electrical components 3.

Key Features of the 4978612 Air Starting Motor

The 4978612 Air Starting Motor is characterized by several key features that enhance its performance and reliability. Its design incorporates robust construction materials, ensuring durability under heavy-duty conditions. The motor is engineered to handle high air pressures and temperatures, making it suitable for demanding applications. Additionally, it features precise machining and quality control processes that contribute to its overall effectiveness.

Benefits of Using the 4978612 Air Starting Motor

Utilizing the 4978612 Air Starting Motor offers several advantages. It provides improved starting reliability, ensuring that the engine starts consistently even under challenging conditions. The motor also reduces wear on the engine by minimizing the reliance on electrical starters, which can be prone to failure under heavy loads. Furthermore, it enhances overall performance by ensuring a smooth and efficient starting process.

Troubleshooting Common Issues

Identifying and addressing common problems associated with the 4978612 Air Starting Motor is important for maintaining its performance. Issues such as leaks in the air system, insufficient air pressure, and mechanical failures can arise. Regular inspections and maintenance can help identify these problems early. Solutions may include repairing or replacing damaged components, ensuring proper air pressure levels, and conducting thorough system checks.

Maintenance Tips

Routine maintenance practices are vital for ensuring the longevity and optimal performance of the 4978612 Air Starting Motor. Inspection procedures should include checking for leaks, verifying air pressure levels, and examining the motor for signs of wear or damage. Lubrication guidelines recommend using high-quality lubricants to reduce friction and wear. Replacement schedules should be followed to ensure that worn-out components are promptly replaced, maintaining the motor’s efficiency.

Integration with Cummins Engines

The 4978612 Air Starting Motor is designed to work seamlessly with Cummins engines. It features specific compatibility features and design considerations that ensure smooth integration. This includes precise fitting and alignment with engine components, as well as compatibility with Cummins’ air starting systems. The motor is engineered to meet the high standards set by Cummins, ensuring reliable performance in heavy-duty applications.

Historical Development

The evolution of air starting motors has seen significant advancements, with Cummins playing a notable role in the technology’s development. The 4978612 model represents the culmination of years of innovation and engineering excellence. Cummins has contributed to the refinement of air starting motor design, incorporating advanced materials and manufacturing techniques to enhance performance and reliability.

Cummins Corporation

Cummins Inc. is a renowned manufacturer in the heavy-duty truck industry, with a rich history of producing high-quality engines and components. The company’s product range includes a variety of engines, powertrains, and related technologies, all designed to meet the demanding needs of heavy-duty applications. Cummins is known for its commitment to innovation, quality, and customer satisfaction, making it a trusted name in the industry.

Compatibility with Cummins Engines

The Cummins Air Starting Motor part number 4978612 is designed to be compatible with a range of Cummins engines, ensuring reliable and efficient starting performance across various applications. This air starting motor is engineered to provide robust starting power, crucial for the reliable operation of the engines it supports.

Compatible Engines

- K19

- QSK19

- CM850

- MCRS

The Cummins Air Starting Motor 4978612 is engineered to fit seamlessly with the K19 and QSK19 engines, both known for their durability and performance in demanding industrial applications. These engines often require a reliable starting motor to handle the high torque and power demands, and the 4978612 part is specifically designed to meet these requirements.

For the CM850 and MCRS engines, the air starting motor 4978612 is equally well-suited. These engines are typically used in heavy-duty applications where consistent and powerful starting is essential. The 4978612 part ensures that these engines can start reliably under various conditions, enhancing overall operational efficiency and uptime.

Installation and Performance

When installing the Cummins Air Starting Motor 4978612 on these engines, it is crucial to follow the manufacturer’s guidelines to ensure proper fitment and performance. The design of the 4978612 part allows for easy integration with the engine’s existing components, minimizing downtime and simplifying the installation process.

The robust construction of the 4978612 air starting motor ensures it can withstand the rigors of continuous use in demanding environments. Its high-efficiency design provides the necessary power to start the engine quickly and reliably, even in challenging conditions.

Reliability and Maintenance

The Cummins Air Starting Motor 4978612 is built to last, with components designed to endure the stresses of heavy-duty use. Regular maintenance and inspection are recommended to ensure the motor continues to perform optimally. Cummins provides comprehensive support and resources to help users maintain their air starting motors, ensuring long-term reliability and performance.

By choosing the Cummins Air Starting Motor 4978612 for their K19, QSK19, CM850, and MCRS engines, users can be confident in the reliability and efficiency of their engine starting systems. This part is a testament to Cummins’ commitment to quality and performance, providing a critical component for the reliable operation of these engines.

Understanding the Role of Part 4978612 Air Starting Motor in Engine Systems

The part 4978612 Air Starting Motor is an essential component in various engine systems, particularly in marine and industrial applications where air start systems are prevalent. This motor is designed to convert pneumatic energy into mechanical energy, facilitating the initial rotation of the engine.

Integration with Engine Components

Motor

The Air Starting Motor is directly connected to the engine’s motor. When activated, it uses compressed air to turn the motor, initiating the engine’s startup sequence. This interaction ensures that the motor receives the necessary torque to overcome inertia and begin the combustion process.

Starting System

In the starting system, the Air Starting Motor works in conjunction with the solenoid valve and the air reservoir. Upon activation, the solenoid valve releases compressed air from the reservoir to the motor. This air pressure drives the piston within the motor, which in turn rotates the engine’s crankshaft. The seamless integration of the Air Starting Motor with the starting system ensures a reliable and efficient engine start, even in demanding conditions.

Operational Synergy

The Air Starting Motor’s role extends beyond mere initiation; it ensures that the engine starts smoothly and consistently. By providing a robust and controlled start, it reduces wear on the engine components and enhances overall engine longevity. The motor’s ability to handle high torque loads during startup is particularly beneficial in large diesel engines, where traditional electric starters might struggle.

Conclusion

In summary, the part 4978612 Air Starting Motor is a pivotal element in the engine’s startup process, ensuring reliable and efficient operation by leveraging pneumatic energy to initiate mechanical motion. Its integration with the motor and starting system underscores its importance in maintaining engine performance and durability.

-

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ -

Drozdziel, P. (2023). The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge.

↩ -

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.