This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

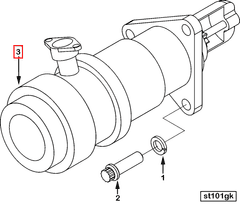

The Cummins 4949449 Air Starting Motor is a specialized component designed for use in commercial trucks. Its primary function is to facilitate the start-up of diesel engines using compressed air, a method that is particularly effective in large, heavy-duty applications. This motor is integral to the efficient operation of commercial trucks, ensuring that engines can be started reliably under various conditions.

Basic Concepts of Air Starting Motors

Air starting motors operate on the principle of using compressed air to initiate engine start-up. In diesel engines, this is achieved by directing high-pressure air into the cylinders, which turns the engine over until it starts running on its own. This method is advantageous for large engines, as it provides the necessary torque to overcome the high inertia without relying solely on electrical power 1.

Purpose of the Cummins 4949449 Air Starting Motor

The Cummins 4949449 Air Starting Motor plays a significant role in the operation of commercial trucks by providing a reliable means to start diesel engines. It uses compressed air to turn the engine over, ensuring that the engine can start even in conditions where electrical systems might struggle, such as in cold weather or when the battery is weak. This motor is designed to integrate seamlessly with Cummins diesel engines, enhancing their performance and reliability 2.

Key Features

The Cummins 4949449 Air Starting Motor is characterized by several key features that make it suitable for heavy-duty applications. These include a robust construction that can withstand the rigors of commercial truck use, a high torque output that ensures reliable engine start-up, and compatibility with a range of Cummins diesel engines. These features contribute to the motor’s durability and effectiveness in various operating conditions 3.

Benefits

The use of the Cummins 4949449 Air Starting Motor offers several benefits. It provides improved starting reliability, ensuring that engines can be started consistently even under challenging conditions. Additionally, it reduces wear on the engine by minimizing the strain on electrical components during start-up. The motor also enhances performance in cold weather conditions, where traditional starting methods might be less effective 4.

Installation and Integration

Proper installation and integration of the Cummins 4949449 Air Starting Motor are crucial for ensuring optimal performance. Recommended procedures include careful alignment with the engine, secure mounting, and proper connection to the compressed air system. Following best practices during installation helps to avoid common issues and ensures that the motor functions as intended within the engine system.

Troubleshooting and Maintenance

Effective troubleshooting and maintenance practices are important for the Cummins 4949449 Air Starting Motor. Common issues may include air leaks, motor malfunctions, or electrical problems. Regular maintenance, such as checking for air leaks, inspecting electrical connections, and ensuring the motor is free from debris, can help to prevent these issues and prolong the motor’s lifespan. Adhering to manufacturer guidelines for maintenance is also recommended.

Safety Considerations

When working with the Cummins 4949449 Air Starting Motor, it is important to be aware of safety considerations. Proper handling of compressed air is crucial, as it can be hazardous if not managed correctly. This includes ensuring that all connections are secure and that the system is pressurized within safe limits. Adhering to manufacturer guidelines and safety protocols helps to mitigate risks associated with the use of compressed air systems.

Cummins Overview

Cummins Inc. is a well-established company with a strong reputation in the diesel engine industry. Founded in 1919, Cummins has a long history of innovation and quality in the production of diesel engines and related components. The company is known for its commitment to developing reliable and efficient solutions for a wide range of applications, including commercial trucks. This reputation is reflected in the design and performance of the Cummins 4949449 Air Starting Motor.

Air Starting Motor 4949449 Compatibility with Cummins Engines

The Air Starting Motor part number 4949449, manufactured by Cummins, is designed to be compatible with a range of Cummins engines, ensuring reliable and efficient engine starting across various applications. This compatibility extends to the following engines:

- G855

- G855 CM558

- N14 G

For the G855 and G855 CM558 engines, the Air Starting Motor 4949449 is engineered to integrate seamlessly with the engine’s design, providing robust starting power while maintaining durability and performance. The motor’s design ensures it can handle the specific demands of these engines, offering consistent starting capabilities under various operating conditions.

In the case of the N14 G engine, the Air Starting Motor 4949449 is tailored to fit the unique specifications of this engine model. This ensures that the motor can effectively engage the starter gear, facilitating smooth and reliable engine starts. The motor’s construction and materials are chosen to withstand the rigors of heavy-duty operations, making it a dependable choice for this engine type.

Overall, the Air Starting Motor 4949449 is a versatile component that can be confidently used with these Cummins engines, providing the necessary starting power while ensuring longevity and reliability in demanding environments.

Role of Part 4949449 Air Starting Motor in Engine Systems

The part 4949449 Air Starting Motor is an essential component in various engine systems, particularly in marine and industrial applications where air starting systems are prevalent. This motor is responsible for converting pneumatic energy into mechanical energy, thereby initiating the engine’s operation.

Integration with Engine Components

-

Starting System: The Air Starting Motor is integrated into the engine’s starting system. When activated, it uses compressed air to turn the engine’s crankshaft, enabling the engine to start. This is particularly useful in large diesel engines where electric starters may not provide sufficient torque.

-

Crankshaft: Directly connected to the crankshaft, the Air Starting Motor ensures a smooth and powerful start. The motor’s robust design allows it to handle the high torque requirements during the starting phase, reducing strain on the crankshaft and other connected components.

-

Compressor: The Air Starting Motor relies on a compressor to supply the necessary pneumatic pressure. The compressor stores air in reservoirs, which are then released to the motor upon starting. This system ensures that the motor has a consistent and reliable source of power.

-

Valve Mechanism: The motor is equipped with valves that control the flow of air into and out of the motor. These valves are synchronized with the engine’s starting sequence to ensure efficient air usage and prevent backflow, which could damage the system.

-

Control System: Modern Air Starting Motors are often paired with electronic control systems that monitor and regulate the starting process. These systems can adjust air pressure and motor engagement based on engine conditions, enhancing reliability and performance.

-

Exhaust System: Post-start, the Air Starting Motor disengages, and the engine takes over. The exhaust system plays a role in dissipating any residual air and ensuring that the engine operates smoothly without interference from the starting motor.

In summary, the part 4949449 Air Starting Motor is a vital element in the starting sequence of engine systems, ensuring reliable and efficient engine starts through its integration with various components such as the crankshaft, compressor, valve mechanism, and control system.

Conclusion

The Cummins 4949449 Air Starting Motor is a critical component for the reliable start-up of diesel engines in commercial trucks. Its robust design, high torque output, and compatibility with various Cummins engines make it an essential part of heavy-duty applications. Proper installation, maintenance, and adherence to safety protocols are crucial for ensuring the motor’s optimal performance and longevity.

-

Livesey, A. (2000). The Repair of Vehicle Bodies. Elsevier.

↩ -

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩ -

Hilgers, M. (2022). Transmissions and Drivetrain Design. Springer Vieweg.

↩ -

Fischer, R., Kucukay, F., Jurgens, G., Najork, R., & Pollak, B. (2015). The Automotive Transmission Book Powertrain. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.