This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

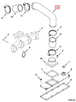

The Cummins 4939972 Air Intake Connection is a component designed for use in commercial trucks equipped with Cummins engines. Its purpose is to facilitate the efficient transfer of air from the intake system to the engine. This part plays a role in maintaining the performance and reliability of the truck’s engine by ensuring a consistent supply of clean, filtered air 2.

Basic Concepts of Air Intake Connection

Air intake connections in diesel engines are integral to the air filtration and delivery system. They connect the air filter to the engine, allowing air to pass through while preventing contaminants from entering the engine. This system ensures that the air entering the engine is clean, which is vital for optimal combustion and engine efficiency 3.

Function and Operation

The Cummins 4939972 Air Intake Connection operates by linking the air intake system to the engine. It interacts with other components such as the turbocharger and intercooler. The connection ensures that pressurized air from the turbocharger is efficiently delivered to the engine, enhancing combustion and overall engine performance. Additionally, it allows for the integration of the intercooler, which cools the compressed air before it enters the engine, further improving efficiency and power output 2.

Purpose of the 4939972 Air Intake Connection

The specific role of the 4939972 Air Intake Connection is to ensure efficient air delivery to the engine. By providing a secure and leak-free connection, it contributes to the engine’s performance and fuel efficiency. This part is designed to withstand the rigors of commercial truck operation, ensuring consistent air flow under various driving conditions 3.

Key Features

The Cummins 4939972 Air Intake Connection is constructed with durable materials to ensure longevity and reliability. It features a robust design that includes specific connection types tailored for Cummins engines. Unique attributes such as reinforced seals and corrosion-resistant materials enhance its functionality and durability in demanding environments 1.

Benefits

The advantages of the Cummins 4939972 Air Intake Connection include improved engine performance due to efficient air delivery, enhanced durability thanks to its robust construction, and ease of installation which minimizes downtime during maintenance procedures 3.

Installation Process

Proper installation of the 4939972 Air Intake Connection involves several steps. First, ensure the engine bay is clean and free of debris. Next, align the connection with the intake system and secure it using the appropriate tools. It may be necessary to use additional components such as clamps or gaskets to ensure a tight seal. Follow the manufacturer’s instructions for torque specifications to avoid over-tightening, which could damage the connection 1.

Maintenance and Care

Routine maintenance of the 4939972 Air Intake Connection includes regular inspections for signs of wear or damage. Cleaning the connection and surrounding areas can prevent buildup that might affect performance. It is also important to check for any leaks in the air intake system, as these can reduce engine efficiency 3.

Troubleshooting Common Issues

Common problems with air intake connections can include leaks, blockages, or damage to the connection itself. To diagnose these issues, inspect the connection for visible signs of wear or damage. Use a pressure gauge to check for leaks in the air intake system. If a leak is detected, the connection may need to be resealed or replaced 1.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history of innovation and a commitment to quality, Cummins provides reliable and efficient power solutions for various industries, including commercial trucking. The company’s extensive product range and focus on technological advancement ensure that their components, like the 4939972 Air Intake Connection, meet the high demands of modern engines 2.

Compatibility with Cummins Engines

The Cummins Air Intake Connection part number 4939972 is designed to integrate seamlessly with a variety of Cummins engine models. This part is crucial for ensuring the efficient flow of air into the engine, which is essential for optimal performance and combustion.

-

4B3.9 Engines: The 4939972 Air Intake Connection is specifically engineered to fit the 4B3.9 engine series. This part ensures a secure and leak-free connection, which is vital for maintaining the engine’s air-to-fuel ratio and overall efficiency.

-

Other Cummins Engines: While the primary focus is on the 4B3.9 engines, the 4939972 Air Intake Connection is also compatible with other Cummins engine models. This versatility makes it a valuable component for various applications, providing a reliable solution for air intake needs across different engine types 2.

Installation and Functionality

The installation of the 4939972 Air Intake Connection is straightforward, designed for ease of use and quick assembly. This part is engineered to withstand the rigors of engine operation, ensuring durability and longevity. Its design facilitates a precise fit, minimizing the risk of air leaks and enhancing the engine’s overall performance 3.

Importance of the Air Intake Connection

The air intake connection plays a pivotal role in the engine’s operation. It ensures that the engine receives the correct amount of air necessary for combustion. A well-functioning air intake connection contributes to improved engine efficiency, reduced emissions, and enhanced power output. This part is a critical component in maintaining the engine’s performance and reliability 1.

Role of Part 4939972 Air Intake Connection in Engine Systems

The part 4939972 Air Intake Connection is a component in the efficient operation of various engine systems. Its primary function is to facilitate the smooth and uninterrupted flow of air into the engine, ensuring optimal performance and efficiency.

Integration with Engine Arrangement

In the context of engine arrangement, the Air Intake Connection plays a role in maintaining the structural integrity and functional efficiency of the intake system. It is designed to connect different sections of the intake tract, ensuring that air flows seamlessly from the air filter to the engine’s combustion chambers. This connection is vital for maintaining the correct air-fuel ratio, which is essential for combustion efficiency and overall engine performance 2.

Interaction with Turbocharger

When integrated with a turbocharger system, the Air Intake Connection becomes even more significant. The turbocharger relies on a consistent and robust airflow to compress the intake air, thereby increasing the engine’s power output. The Air Intake Connection ensures that the airflow remains stable and unimpeded, allowing the turbocharger to operate efficiently.

In turbocharged engines, the Air Intake Connection must be durable and well-sealed to withstand the increased pressure and temperature conditions. It helps in directing the compressed air from the turbocharger to the intake manifold, ensuring that the engine receives a dense charge of air for combustion. This results in improved engine performance and power delivery 3.

Conclusion

The Cummins 4939972 Air Intake Connection is a vital component in the efficient operation of Cummins engines. Its robust design, ease of installation, and compatibility with various engine models make it an essential part for maintaining engine performance and reliability. Regular maintenance and proper installation are key to ensuring the longevity and efficiency of this part.

-

Deanna Sclar, Auto Repair for Dummies: 2nd Edition, For Dummies, 2008.

↩ ↩ ↩ ↩ -

Haoran Hu, Simon J Baseley and Xubin Song, Advanced Hybrid Powertrains for Commercial Vehicles Second Edition, SAE International, 2021.

↩ ↩ ↩ ↩ ↩ -

John Dixon, Modern Diesel Technology Preventive Maintenance and Inspection, Delmar Cengage Learning, 2010.

↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.