This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

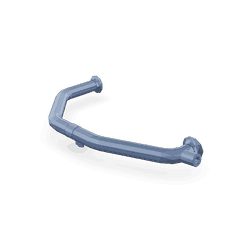

The Air Transfer Tube, identified by part number 4939575, is a component manufactured by Cummins, a leading name in the commercial truck industry. This tube is integral to the air system of commercial trucks, facilitating efficient air distribution and pressure management. Cummins is renowned for its commitment to quality and innovation, ensuring that components like the Air Transfer Tube meet the rigorous demands of heavy-duty applications 1.

Function and Operation

The Air Transfer Tube operates within the truck’s air system by directing compressed air from the compressor to various components that require pressurized air to function, such as the brakes, suspension, and other pneumatic systems. It plays a role in maintaining consistent air pressure throughout the system, which is vital for the reliable operation of these components. The tube is designed to handle high-pressure air efficiently, ensuring that air is distributed evenly and without significant loss of pressure 2.

Key Features

This Cummins part is constructed from durable materials that can withstand the high pressures and temperatures encountered in commercial truck air systems. Its design includes reinforced sections to prevent kinking and ensure a smooth flow of air. The tube is also resistant to abrasion and corrosion, which enhances its longevity in demanding environments. Additionally, the tube features secure connection points that ensure a tight seal, minimizing the risk of air leaks.

Benefits

The Air Transfer Tube offers several advantages that contribute to the overall efficiency and reliability of the truck’s air system. By ensuring consistent air distribution, it helps maintain the performance of pneumatic components. This reliability can lead to reduced downtime and lower maintenance costs for fleet operators. Furthermore, the tube’s durable construction and resistance to wear and tear contribute to its long service life, providing value over time 3.

Installation and Integration

Proper installation of the Air Transfer Tube is crucial for its effective operation. It should be installed according to the manufacturer’s guidelines, which may include specific torque settings for connection points and the use of compatible fittings. The tube integrates seamlessly with other components of the truck’s air system, such as the compressor and distribution valves, ensuring a cohesive and efficient air management system.

Maintenance and Troubleshooting

To ensure optimal performance, the Air Transfer Tube should be inspected regularly for signs of wear, such as cracks or abrasions. It is also important to check connection points for leaks and ensure that they remain secure. Common issues may include air leaks or reduced air pressure, which can often be traced back to the tube or its connections. Troubleshooting steps may involve inspecting the tube for physical damage, checking connection points for tightness, and ensuring that there are no obstructions in the air flow.

Safety Considerations

When working with the Air Transfer Tube, it is important to observe safety protocols to prevent injury and ensure the component’s integrity. This includes wearing appropriate personal protective equipment, such as gloves and safety glasses, when handling the tube. Additionally, the system should be depressurized before any work is performed to avoid the risk of injury from high-pressure air. Awareness of potential hazards, such as sharp edges or hot surfaces, is also important when working around the air system components.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial vehicle and engine industry. The company’s commitment to excellence is reflected in its wide range of products, including the Air Transfer Tube, which is designed to meet the demanding requirements of commercial truck applications.

Air Transfer Tube (Part 4939575) Compatibility with Cummins Engines

The Air Transfer Tube (part number 4939575) manufactured by Cummins is a critical component in the air management system of various Cummins engines. This part is designed to facilitate the transfer of air within the engine’s air intake system, ensuring efficient and smooth operation.

ISB (Chrysler)

The ISB engine, developed by Cummins and utilized in Chrysler vehicles, is one of the engines that can incorporate the Air Transfer Tube part 4939575. This part is integral to the engine’s air intake system, ensuring that the air is properly directed and managed. The ISB engine is known for its robust performance and reliability, making it a popular choice in various applications, including commercial vehicles and heavy-duty machinery.

In the ISB engine, the Air Transfer Tube connects different sections of the air intake system, ensuring that the air flow is optimized. This helps in maintaining the engine’s performance and efficiency, contributing to its overall reliability and longevity. The precise fit and function of this part are crucial for the engine’s operation, as any discrepancies can lead to inefficiencies and potential performance issues.

Role of Part 4939575 Air Transfer Tube in Engine Systems

The 4939575 Air Transfer Tube is an essential component in the efficient operation of various engine systems. It is primarily utilized in the arrangement and management of exhaust recirculation air, ensuring optimal performance and emissions control.

In the context of exhaust recirculation (EGR) systems, the Air Transfer Tube facilitates the redirection of a portion of the exhaust gases back into the intake manifold. This process helps in reducing nitrogen oxides (NOx) emissions by lowering the combustion temperature. The tube ensures a smooth and controlled flow of these gases, which is vital for maintaining engine efficiency and compliance with emissions standards.

Within the plumbing of the engine’s air management system, the Air Transfer Tube connects various components, such as the EGR valve, the intake manifold, and the exhaust system. Its role is to provide a dedicated pathway for the recirculated exhaust gases, preventing any potential leaks or inefficiencies that could arise from using less specialized components.

Overall, the 4939575 Air Transfer Tube plays a significant role in enhancing the performance and environmental compliance of engine systems by ensuring precise control over the flow of exhaust recirculation air.

Conclusion

The Air Transfer Tube, part number 4939575, is a vital component in the air management systems of commercial trucks and engines. Its role in facilitating efficient air distribution, maintaining consistent air pressure, and ensuring the smooth operation of pneumatic systems underscores its importance. The tube’s durable construction, resistance to wear and tear, and secure connection points contribute to its reliability and longevity. Proper installation, regular maintenance, and adherence to safety protocols are essential for maximizing the benefits of this Cummins part. As a component of Cummins’ extensive range of high-quality products, the Air Transfer Tube exemplifies the company’s commitment to innovation and excellence in the commercial vehicle and engine industry.

-

Peters, G., & Peters, B. J. (2002). Automobile Vehicle Safety. CRC Press.

↩ -

Sheng, G. (2012). Vehicle Noise, Vibration and Sound Quality. SAE International.

↩ -

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., & Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.