This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

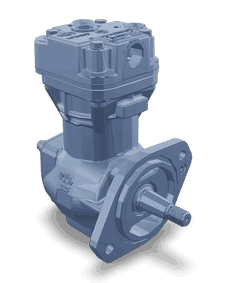

The Cummins 4932265 Air Compressor is a specialized component designed for use in commercial trucks. It plays a role in generating compressed air, which is necessary for various truck systems, including braking, suspension, and other pneumatic controls. The compressor’s efficiency and reliability are important for maintaining the operational integrity of commercial vehicles, ensuring safety and performance on the road.

Basic Concepts of Air Compressors

Air compressors are mechanical devices that convert power into potential energy stored in pressurized air. They operate by drawing in air, compressing it, and storing it in a tank until needed. In commercial trucks, air compressors are integral to the operation of air brake systems, suspension systems, and other pneumatic components. The compressed air generated by these compressors provides the force required for these systems to function effectively 1.

Purpose of the Cummins 4932265 Air Compressor

This Cummins part plays a role in the operation of a truck by generating compressed air. This air is used to power the truck’s braking system, suspension system, and other pneumatic controls. The compressor ensures that these systems have a consistent and reliable source of compressed air, which is important for their operation. By maintaining adequate air pressure, the compressor helps ensure the truck’s safety and performance.

Key Features

This part is designed with several features that enhance its performance and durability. It is constructed using high-quality materials that resist wear and corrosion, ensuring longevity. The compressor’s design includes advanced technological aspects that improve its efficiency and reliability. These features contribute to the compressor’s ability to deliver consistent performance under various operating conditions.

Benefits

This part offers several advantages for truck operations. Its efficient design ensures that it can generate the required amount of compressed air with minimal energy consumption. The compressor’s reliability reduces the likelihood of downtime, enhancing the truck’s overall performance. Additionally, its durable construction ensures that it can withstand the rigors of commercial use, providing long-term value to fleet operators.

Installation and Integration

Proper installation and integration of this part into a truck’s system are important for ensuring its optimal performance. Installation should be performed by qualified technicians who understand the compressor’s requirements and the truck’s system. Prerequisites may include ensuring that the truck’s electrical system can support the compressor and that the mounting location is suitable. Careful integration ensures that the compressor operates efficiently and reliably.

Troubleshooting Common Issues

Common issues with this part may include insufficient air pressure, unusual noises, or leaks. Troubleshooting these problems involves checking the compressor’s connections, inspecting for leaks, and ensuring that the compressor is receiving adequate power. Solutions may range from tightening connections to replacing worn components. Regular inspections can help identify and address issues before they lead to significant problems.

Maintenance Tips

Regular maintenance is key to ensuring the longevity and optimal performance of this part. This includes checking for leaks, ensuring that connections are secure, and inspecting the compressor for signs of wear. Lubrication of moving parts and replacement of filters are also important maintenance practices. Adhering to a maintenance schedule helps prevent issues and ensures that the compressor continues to operate efficiently.

Safety Considerations

When working with this part, it is important to observe safety guidelines to prevent accidents. This includes ensuring that the compressor is turned off and depressurized before performing any maintenance or repairs. Protective equipment, such as gloves and safety glasses, should be worn to protect against potential hazards. Following these safety precautions helps ensure a safe working environment.

Cummins Company Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes diesel and natural gas engines, as well as related technologies. Founded in 1919, the company has a long history of innovation and excellence in the industry. Cummins is known for its commitment to quality and customer satisfaction, providing reliable and efficient solutions for a wide range of applications, including commercial trucks. The company’s expertise and reputation make it a trusted name in the industry.

Cummins Engine Compatibility with AIR COMPRESSOR Part 4932265

The Cummins AIR COMPRESSOR part number 4932265 is designed to fit a range of Cummins engines, ensuring efficient operation and reliability across various applications. This part is compatible with the following engines:

- B4.5 CM2350 B129B

- D4.0 CM2620 D103B

- F3.8 CM2350 F120B

- F3.8 CM2350 F128C

- F3.8 CM2620 F137B

- F4.5 CM2620 F139B

Additionally, the AIR COMPRESSOR part 4932265 is also compatible with the following ISF engines:

- ISF3.8 CM2220 AN

- ISF3.8 CM2220 F103

- ISF3.8 CM2350 F109

- ISF4.5 CM2220 F123

This compatibility ensures that the AIR COMPRESSOR part 4932265 can be effectively used across a diverse range of Cummins engines, providing essential functionality and performance.

Role of Part 4932265 Air Compressor in Engine Systems

The 4932265 Air Compressor is an integral component within various engine systems, facilitating the efficient operation of several key functions. Its primary role is to supply compressed air, which is essential for the proper functioning of multiple engine components.

Fuel Injection System

In modern fuel injection systems, the 4932265 Air Compressor provides the necessary pressurized air required for the operation of fuel injectors. This compressed air assists in atomizing the fuel, ensuring a finer spray that enhances combustion efficiency and reduces emissions.

Turbocharger System

When integrated with a turbocharger system, the air compressor plays a significant role in boosting engine performance. It compresses the intake air before it enters the turbocharger, increasing the air density. This results in more oxygen being available for combustion, which in turn allows the engine to produce more power without increasing its physical size.

Brake System

In vehicles equipped with air brake systems, the 4932265 Air Compressor is responsible for building and maintaining the required air pressure. This pressurized air is then used to operate the brake calipers or drums, ensuring reliable and responsive braking performance.

Suspension System

Some advanced suspension systems utilize air springs that rely on compressed air to adjust ride height and damping characteristics. The air compressor provides the consistent air pressure needed to maintain optimal suspension performance, enhancing both comfort and handling.

Cabin Comfort Systems

In addition to its mechanical functions, the air compressor also supports cabin comfort systems. It supplies compressed air for the operation of air suspension seats, climate control systems, and other pneumatic components, contributing to a more comfortable driving environment.

Aftertreatment Systems

In diesel engines, the air compressor can be part of the aftertreatment system, providing pressurized air for the operation of components like Diesel Particulate Filters (DPF) and Selective Catalytic Reduction (SCR) systems. This ensures that emissions are effectively managed and regulated.

By understanding the multifaceted role of the 4932265 Air Compressor, engineers and mechanics can better appreciate its importance in maintaining the overall efficiency and performance of engine systems.

Conclusion

The Cummins 4932265 Air Compressor is a critical component in commercial truck systems, ensuring the efficient operation of braking, suspension, and other pneumatic controls. Its design, featuring high-quality materials and advanced technology, contributes to its durability and reliability. Proper installation, regular maintenance, and adherence to safety guidelines are essential for maximizing the performance and longevity of this part. Cummins Inc.’s reputation for quality and innovation underscores the trust and reliability associated with this compressor.

-

Wharton, A. J. (1991). Diesel Engines. Butterworth-Heinemann Ltd.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.