This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4364452 Air Fuel Mixer is designed to enhance the performance and efficiency of heavy-duty truck engines. It ensures the optimal mixture of air and fuel before combustion, which is essential for engine operation. This part plays a role in maintaining engine efficiency, power output, and emissions levels 1.

Basic Concepts of Air Fuel Mixers

An air fuel mixer combines air and fuel in the correct proportions for efficient combustion. Proper air-fuel ratio management is fundamental to engine performance, ensuring peak efficiency, maximum power, and minimized emissions. The mixer delivers a consistent and precise air-fuel ratio, which is vital for the combustion process 2.

Role of the 4364452 Air Fuel Mixer in Truck Operation

The 4364452 Air Fuel Mixer is integral to the engine system of a truck. It ensures that air and fuel are mixed in the optimal ratio before entering the combustion chamber. This precise mixture enhances engine performance by improving combustion efficiency, leading to better power output and fuel economy. It also helps reduce emissions by ensuring more complete fuel combustion 3.

Key Features of the 4364452 Air Fuel Mixer

The 4364452 Air Fuel Mixer is characterized by several key features. Its design provides a consistent and accurate air-fuel mixture. The materials used in its construction are chosen for their durability and resistance to high temperatures and pressures within the engine. Technological advancements incorporated into the mixer enhance its performance and reliability.

Benefits of Using the 4364452 Air Fuel Mixer

Utilizing the 4364452 Air Fuel Mixer offers several advantages. It contributes to improved engine performance by ensuring optimal combustion, resulting in enhanced power output and better fuel efficiency. Additionally, the mixer aids in reducing emissions, making it an environmentally friendly choice. The precise air-fuel ratio it maintains also leads to smoother engine operation and increased reliability.

Installation and Integration

When installing the 4364452 Air Fuel Mixer, it is important to consider its compatibility with various engine models and systems. Proper installation ensures that the mixer functions correctly and integrates seamlessly with the engine’s other components. Following manufacturer guidelines and recommendations is crucial for a successful installation.

Maintenance and Troubleshooting

Regular maintenance of the 4364452 Air Fuel Mixer is essential to ensure its continued optimal performance. This includes periodic inspections, cleaning, and replacing any worn-out components. Troubleshooting common issues, such as inconsistent air-fuel ratios or performance drops, involves checking the mixer for any signs of damage or malfunction and addressing them promptly.

Performance Optimization

To optimize the performance of the 4364452 Air Fuel Mixer, several tips and techniques can be employed. This may include fine-tuning the air-fuel ratio settings, ensuring that all components are in good working condition, and considering upgrades or modifications that can further enhance its efficiency. Regular monitoring and adjustments can lead to improved engine performance and fuel economy.

Common Myths and Misconceptions

There are several myths and misconceptions surrounding air fuel mixers. One common misunderstanding is that any air fuel mixer will provide the same level of performance. In reality, the design, materials, and technological features of a mixer can significantly impact its effectiveness. Another myth is that frequent adjustments are necessary for optimal performance, whereas regular maintenance and proper installation often suffice.

About Cummins

Cummins Inc. is a renowned manufacturer in the automotive industry, known for its high-quality engines and components. With a rich history and a diverse product range, Cummins has established a strong reputation for reliability and innovation. The company’s commitment to excellence is reflected in its products, including the 4364452 Air Fuel Mixer, which is designed to meet the demanding requirements of heavy-duty truck engines.

Compatibility with Cummins Engines

The Air Fuel Mixer part 4364452, manufactured by Cummins, is a critical component in ensuring optimal engine performance across various Cummins engine models. This part is integral to the engine’s air management system, facilitating the precise mixing of air and fuel to enhance combustion efficiency and reduce emissions.

KTA19GC CM558 Engines

The KTA19GC CM558 engine series is designed for heavy-duty applications, including marine and industrial use. The Air Fuel Mixer part 4364452 is specifically engineered to fit within the intricate design of the KTA19GC CM558 engines, ensuring seamless integration and reliable operation. This part’s compatibility with the KTA19GC CM558 engines underscores its versatility and importance in maintaining the engine’s performance standards.

Grouping of Compatible Engines

While the primary focus here is on the KTA19GC CM558 engines, it is worth noting that the Air Fuel Mixer part 4364452 is also compatible with other Cummins engine models that share similar design and operational requirements. This compatibility extends to various engine groups within the Cummins portfolio, ensuring that the part can be utilized across multiple platforms without compromising on performance or reliability.

By ensuring that the Air Fuel Mixer part 4364452 is correctly installed and maintained, engine operators can expect improved fuel efficiency, reduced emissions, and enhanced overall engine performance. This part’s design and functionality make it an essential component for any Cummins engine, contributing to the engine’s ability to meet stringent regulatory standards and operational demands.

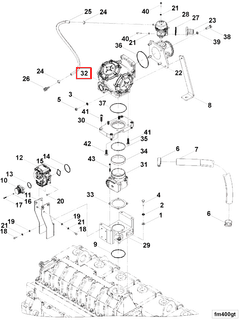

Role of Part 4364452 Air Fuel Mixer in Engine Systems

The Air Fuel Mixer, identified by part number 4364452, is integral to the efficient operation of engine systems by ensuring the precise mixture of air and fuel before it enters the combustion chamber. This component works in concert with several other key components to maintain optimal engine performance.

Interaction with the Fuel Control Module

The Air Fuel Mixer interfaces directly with the Fuel Control Module (FCM). The FCM regulates the amount of fuel delivered to the mixer based on various engine parameters such as load, speed, and temperature. The Air Fuel Mixer then combines this measured fuel with the appropriate amount of air, creating a combustible mixture. This precise mixture is essential for efficient combustion, which in turn affects engine power, fuel efficiency, and emissions.

Coordination with the Module

In more advanced engine systems, the Air Fuel Mixer also works with a broader Module that may include sensors and actuators. These modules often incorporate feedback loops that monitor the air-fuel ratio and make real-time adjustments. The Air Fuel Mixer responds to signals from this Module, fine-tuning the mixture to adapt to changing engine conditions. This dynamic interaction ensures that the engine operates within its optimal range under all conditions.

Integration with Fuel Control Systems

Fuel Control systems, which may include components like fuel injectors and pressure regulators, rely on the Air Fuel Mixer to deliver a consistent and accurate air-fuel mixture. The mixer’s ability to maintain this balance is vital for the Fuel Control system’s effectiveness. Whether the engine is idling, accelerating, or decelerating, the Air Fuel Mixer ensures that the Fuel Control system receives the correct input to make necessary adjustments.

Conclusion

In summary, the Air Fuel Mixer (part 4364452) plays a significant role in the engine’s fuel delivery and combustion process. Its integration with the Fuel Control Module, broader Module systems, and Fuel Control components ensures that the engine operates efficiently and effectively across a wide range of conditions.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.