This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

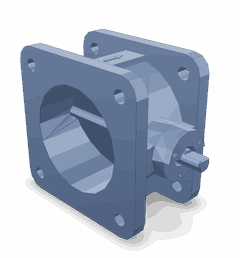

The Cummins 4304872 Air-Fuel Throttle Valve is a component designed to regulate the air-fuel mixture in heavy-duty truck engines. Its purpose is to ensure that the engine operates efficiently by maintaining the optimal air-fuel ratio necessary for combustion. This valve plays a role in the overall performance and efficiency of heavy-duty trucks, contributing to both engine power and fuel economy.

Basic Concepts of Air-Fuel Throttle Valves

An Air-Fuel Throttle Valve is a device that controls the amount of air and fuel entering the engine’s combustion chamber. By adjusting the air-fuel mixture, the valve helps to optimize combustion, which is important for engine performance. The valve operates by responding to signals from the engine control unit (ECU), which monitors various engine parameters to determine the ideal air-fuel ratio. This ensures that the engine runs smoothly and efficiently under different operating conditions 1.

Purpose and Role in Truck Operation

The Cummins 4304872 Air-Fuel Throttle Valve is specifically designed for use in heavy-duty truck engines. It contributes to engine performance by ensuring that the air-fuel mixture is consistently optimal, which enhances power output and fuel efficiency. Additionally, the valve plays a role in emissions control by helping to reduce the amount of harmful pollutants released into the atmosphere. This is particularly important in meeting regulatory standards for emissions in the trucking industry 2.

Key Features

The Cummins 4304872 Air-Fuel Throttle Valve features a robust design that includes high-quality materials to ensure durability and reliability. Its construction allows for precise control of the air-fuel mixture, which is important for maintaining engine performance. The valve is engineered to withstand the demanding conditions of heavy-duty truck operation, providing consistent performance over time.

Benefits

Using the Cummins 4304872 Air-Fuel Throttle Valve offers several benefits. It contributes to improved engine efficiency by ensuring that the air-fuel mixture is always optimal, which can lead to better fuel economy. Additionally, the valve helps to reduce emissions, making it an environmentally friendly choice. Compared to other similar components, the Cummins valve is known for its reliability and performance, making it a preferred option for heavy-duty truck applications 3.

Installation and Compatibility

Proper installation of the Cummins 4304872 Air-Fuel Throttle Valve is important for ensuring its effective operation. The installation process involves several steps, including preparing the engine compartment, using the appropriate tools, and following the manufacturer’s guidelines to ensure a correct fit. The valve is compatible with various Cummins engine models, and it is important to verify compatibility with the specific engine and system in use to ensure optimal performance.

Troubleshooting and Maintenance

Common issues with the Cummins 4304872 Air-Fuel Throttle Valve may include malfunctions due to wear or contamination. Troubleshooting steps may involve inspecting the valve for signs of damage, cleaning or replacing components as necessary, and ensuring that it is properly connected to the engine control system. Regular maintenance, including periodic inspections and servicing, can help to ensure the longevity and optimal performance of the valve.

Performance and Efficiency

The Cummins 4304872 Air-Fuel Throttle Valve has a notable impact on engine performance and fuel efficiency. By maintaining the optimal air-fuel mixture, the valve helps to ensure that the engine operates at peak efficiency, which can lead to improvements in both power output and fuel economy. Real-world applications have shown measurable improvements in truck operations when using this valve, demonstrating its effectiveness in enhancing engine performance 4.

Regulatory Compliance and Emissions

The Cummins 4304872 Air-Fuel Throttle Valve assists in meeting emissions regulations and standards by helping to reduce harmful emissions. Its role in controlling the air-fuel mixture ensures that the engine combusts fuel more cleanly, which contributes to lower emissions. This is an important aspect of environmental sustainability in trucking operations, as it helps to minimize the industry’s impact on air quality.

Cummins Overview

Cummins Inc. is a well-established company with a strong reputation in the automotive and heavy-duty truck industry. Founded with a commitment to innovation, quality, and customer satisfaction, Cummins has a long history of manufacturing reliable and high-performance engine components. The company’s dedication to these principles is evident in the design and production of the 4304872 Air-Fuel Throttle Valve, which is a testament to Cummins’ expertise and commitment to excellence in the field of engine technology.

Compatibility with Cummins Engines

The Air-Fuel Throttle Valve, part number 4304872, manufactured by Cummins, is a component in the engine’s air management system. This part is designed to regulate the airflow into the engine, ensuring optimal combustion efficiency and performance.

KTA19GC CM558 Engines

The Air-Fuel Throttle Valve is compatible with the KTA19GC CM558 engine series. This engine is known for its robust design and high power output, making it suitable for various industrial applications. The valve’s precise control over the air-fuel mixture enhances the engine’s performance, ensuring it operates at peak efficiency under varying load conditions.

Group Compatibility

The Air-Fuel Throttle Valve is also compatible with other Cummins engines within the same series. These engines share similar design principles and operational requirements, ensuring that the valve fits seamlessly and functions effectively. The compatibility extends to engines that utilize similar air management systems, providing a reliable solution for maintaining engine performance across different models.

Role in Engine Systems

The Air-Fuel Throttle Valve, identified by part number 4304872, is integral to the efficient operation of engine systems by regulating the air-fuel mixture. This component works in conjunction with the throttle valve to ensure precise control over the air intake, which directly influences the combustion process.

When the throttle valve opens, it allows air to enter the intake manifold. The Air-Fuel Throttle Valve modulates the amount of air mixed with the fuel, optimizing the air-fuel ratio for various engine operating conditions. This precise control is important for maintaining engine performance, fuel efficiency, and emissions compliance.

In modern engine systems, the Air-Fuel Throttle Valve is often part of an electronic throttle control (ETC) system. Here, it receives signals from the engine control unit (ECU) to adjust the air-fuel mixture in real-time based on driving conditions, such as acceleration, deceleration, and idle. This dynamic adjustment ensures that the engine operates within optimal parameters, enhancing overall performance and reliability.

Additionally, the Air-Fuel Throttle Valve interacts with other components such as the mass airflow sensor (MAF), oxygen sensors, and the fuel injectors. The MAF sensor measures the amount of air entering the engine, providing data to the ECU. The oxygen sensors monitor the exhaust gases to ensure the air-fuel mixture is correct. The fuel injectors then deliver the appropriate amount of fuel based on the ECU’s calculations, working in harmony with the Air-Fuel Throttle Valve to achieve the desired air-fuel ratio.

Conclusion

The Cummins 4304872 Air-Fuel Throttle Valve is a critical component in the efficient operation of heavy-duty truck engines. By regulating the air-fuel mixture, this part ensures optimal engine performance, fuel efficiency, and emissions compliance. Its robust design, compatibility with various Cummins engines, and integration with modern engine systems make it a reliable and effective solution for maintaining engine performance across different applications.

-

Bartz, W. J. (2019). Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press.

↩ -

Bonnick, A. (2004). A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier.

↩ -

Caines, A. J., Haycock, R. F., & Hillier, J. E. (2004). Automotive Lubricants Reference Book. SAE International.

↩ -

Parikyan, T. Ed. (2022). Advances in Engine and Powertrain Research and Technology. Springer Nature.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.