This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

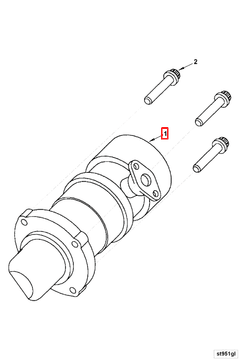

The Cummins 4099474 Air Starting Motor is a specialized component designed for use in commercial trucks. It facilitates the starting process of diesel engines by using compressed air, ensuring reliable engine starts under various conditions, including cold or harsh environments.

Basic Concepts of Air Starting Motors

An air starting motor uses compressed air to turn over a diesel engine, allowing it to start. Unlike traditional electric starters, air starting motors rely on the pressure of compressed air stored in tanks to initiate engine rotation. This system is particularly effective in heavy-duty trucks, where the large size and weight of diesel engines can make electric starting less efficient 1.

Purpose of the Cummins 4099474 Air Starting Motor

The Cummins 4099474 Air Starting Motor uses compressed air to turn the engine over, which is especially beneficial in cold or harsh conditions where electric starters may struggle due to battery performance issues or the increased viscosity of engine oil. This motor ensures that trucks can operate efficiently regardless of external conditions 2.

Key Features

The Cummins 4099474 Air Starting Motor features robust construction materials to withstand heavy-duty use and includes precise air flow control mechanisms to ensure efficient operation. These features contribute to the motor’s durability and effectiveness in starting diesel engines 3.

Benefits of Using the Cummins 4099474 Air Starting Motor

Incorporating this motor into truck fleets offers several advantages, including improved starting reliability, reduced starting times, and potential fuel savings over time due to more efficient engine operation 4.

Installation and Integration

Proper installation and integration of the Cummins 4099474 Air Starting Motor require attention to compatibility and system requirements. Guidelines for installation should be followed to ensure that the motor is correctly connected to the truck’s compressed air system and that all safety measures are observed.

Troubleshooting and Maintenance

Common issues with air starting motors can include leaks in the air system, insufficient air pressure, or mechanical failures. Troubleshooting steps may involve checking for leaks, ensuring adequate air pressure, and inspecting the motor for signs of wear or damage. Regular maintenance practices, such as cleaning and lubricating moving parts, are important to ensure the longevity and optimal performance of the motor.

Performance in Various Conditions

The Cummins 4099474 Air Starting Motor is designed to perform under a range of environmental conditions. Its ability to start engines in extreme temperatures or high-altitude operations makes it a versatile component for commercial trucks. The motor’s robust design and efficient use of compressed air ensure reliable performance, even when faced with challenging environmental factors.

Cummins Company Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins has established itself as a pioneer in diesel engine technology and related systems. The company’s product range includes engines, filtration, emissions solutions, and power generation products. Cummins is committed to innovation, sustainability, and customer success in the diesel engine and related technologies market.

Compatibility with Cummins Engines

The Cummins Air Starting Motor part number 4099474 is designed to provide the necessary power to start the engine by utilizing compressed air. It is compatible with various Cummins engines, ensuring reliable and efficient operation.

G5.9 Engine Series

The G5.9 engine series integrates the Cummins Air Starting Motor 4099474 seamlessly into its starting system. This motor is engineered to withstand the demanding conditions of the G5.9 engines, ensuring quick and dependable starts even in harsh environments. The design of the 4099474 motor allows it to interface perfectly with the engine’s components, providing the necessary torque and speed to initiate the engine’s combustion process effectively.

Integration with Engine Components

- Motor: The Air Starting Motor is directly connected to the engine’s motor. When activated, it uses the force generated by the compressed air to rotate the motor, ensuring that the engine components begin their operational cycles.

- Starting System: In the starting system, the Air Starting Motor plays a pivotal role. It is often integrated with the starter solenoid and the battery system. When the starting sequence is initiated, the solenoid engages, allowing electrical current to flow to the Air Starting Motor. This current activates the motor, which then uses the compressed air to turn the engine over.

- Compressed Air System: The efficiency of the Air Starting Motor is highly dependent on the compressed air system. This system includes components such as air compressors, air tanks, and air lines. The Air Starting Motor requires a consistent supply of high-pressure air to function effectively. The compressed air system ensures that this requirement is met, providing the necessary force to start the engine.

- Engine Control Unit (ECU): Modern engine systems often include an ECU that monitors and controls various engine functions. The Air Starting Motor may be interfaced with the ECU to ensure precise timing and coordination during the start-up process. The ECU can adjust the air pressure and motor activation to optimize engine performance.

- Safety Mechanisms: In many engine systems, safety mechanisms are in place to prevent damage during start-up. The Air Starting Motor may be equipped with sensors that monitor air pressure and motor performance. These sensors provide feedback to the ECU, allowing it to make real-time adjustments and ensure safe operation.

- Maintenance Systems: Regular maintenance of the Air Starting Motor is essential for reliable engine performance. Maintenance systems may include diagnostic tools that monitor the motor’s condition, identify potential issues, and schedule necessary repairs or replacements. This proactive approach helps maintain the efficiency and longevity of the engine system.

Conclusion

The Cummins 4099474 Air Starting Motor is a critical component in the starting system of various engines, ensuring reliable and efficient operation. Its integration with engine components and compatibility with specific engine models, such as the G5.9 series, highlights its importance in maintaining engine efficiency and reliability. Regular maintenance and proper installation are essential to ensure the longevity and optimal performance of this motor.

-

Quansheng Zhan, Shengbo Eben, Li Kun Deng. Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning, 2018.

↩ -

Haoran Hu, Simon J Baseley and Xubin Song. Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International, 2021.

↩ -

MJ Nunney. Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann, 2007.

↩ -

Cummins Inc. Owners Manual for B6.7 CM2450 B181B. Bulletin Number 5677153.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.