This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4057977 Air Starting Motor is a specialized component designed for use in commercial trucks. Its primary function is to facilitate the start-up of diesel engines using compressed air, a method that is both efficient and reliable. This motor is integral to the operation of heavy-duty trucks, ensuring that engines can be started quickly and smoothly under various conditions.

Basic Concepts of Air Starting Motors

Air starting motors operate on the principle of using compressed air to initiate engine start-up. In diesel engines, this is achieved by directing high-pressure air into the cylinders, which turns the engine over until it starts running on its own. This method is particularly effective in large, heavy-duty engines where traditional electric starters may struggle to provide sufficient torque 1.

Purpose and Role in Truck Operation

The Cummins 4057977 Air Starting Motor plays a significant role in the operation of commercial trucks by providing a reliable means to start the engine. It uses the truck’s compressed air system to turn the engine over, ensuring that the diesel engine can start even in cold weather or after long periods of inactivity. This motor is designed to handle the high torque requirements of large diesel engines, making it an indispensable component in the starting system 2.

Key Features

The Cummins 4057977 Air Starting Motor is characterized by several key features that enhance its performance and reliability. It is constructed from durable materials to withstand the rigors of heavy-duty use. The motor’s design includes precision-machined components to ensure smooth operation and efficient use of compressed air. Additionally, it incorporates advanced sealing technologies to prevent air leaks, which could reduce starting efficiency 3.

Benefits

Using the Cummins 4057977 Air Starting Motor offers several benefits. It provides improved starting reliability, ensuring that the engine can be started quickly and efficiently under a variety of conditions. This motor also reduces wear on the engine by minimizing the stress associated with starting, leading to longer engine life. Furthermore, it enhances overall truck performance by ensuring that the engine starts reliably, which is critical for maintaining schedules and productivity in commercial operations.

Troubleshooting and Maintenance

To ensure optimal performance and longevity, regular maintenance and troubleshooting of the Cummins 4057977 Air Starting Motor are recommended. Common issues may include air leaks, worn seals, or electrical problems. Regular inspections and maintenance checks can help identify these issues early, allowing for timely repairs. Additionally, ensuring that the compressed air system is properly maintained will contribute to the efficient operation of the air starting motor.

Integration with Truck Systems

The Cummins 4057977 Air Starting Motor is designed to integrate seamlessly with other systems within the truck, such as the air compressor and engine control unit (ECU). This integration ensures that the starting process is coordinated with other engine functions, providing a smooth and efficient start-up experience. The motor is compatible with a range of Cummins engines, ensuring that it can be used across different truck models and applications.

Performance in Various Conditions

The Cummins 4057977 Air Starting Motor is engineered to perform reliably under a wide range of operating conditions. Whether facing extreme temperatures, high altitudes, or heavy-duty applications, this motor is designed to deliver consistent performance. Its robust construction and advanced design features ensure that it can handle the demands of commercial truck operations, providing reliable starting power in all situations.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel engines and related components. With a history of innovation and a commitment to quality, Cummins has established a reputation for producing reliable and high-performance products. The company’s focus on research and development ensures that its products, like the Cummins 4057977 Air Starting Motor, continue to meet the evolving needs of the commercial truck industry.

Compatibility with Cummins Engines

The Cummins 4057977 Air Starting Motor is designed to be compatible with a range of engines, including the G855, N14 MECHANICAL, and NH/NT 855 models. This air starting motor is engineered to provide reliable and efficient starting power for these engines, ensuring smooth operation and performance.

For the G855 engine, the air starting motor is a critical component that interfaces seamlessly with the engine’s design, offering robust starting capabilities even in demanding conditions. Its integration with the G855 ensures that the engine can be started quickly and reliably, contributing to overall operational efficiency.

In the case of the N14 MECHANICAL engine, the air starting motor part 4057977 is specifically tailored to meet the mechanical requirements of this engine model. The design ensures that it can handle the mechanical stresses and deliver the necessary torque for starting the engine, making it an essential part of the engine’s starting system.

Similarly, for the NH/NT 855 engines, the air starting motor is engineered to fit perfectly within the engine’s architecture. This ensures that the motor can efficiently engage with the engine’s components, providing the required power to start the engine reliably. The compatibility of this part with the NH/NT 855 models highlights its versatility and effectiveness across different engine types.

Role of the Cummins 4057977 Air Starting Motor in Engine Systems

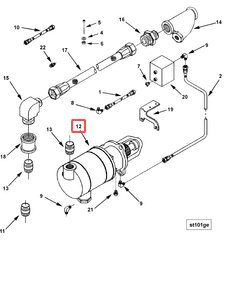

The Cummins 4057977 Air Starting Motor is an integral component in various engine systems, facilitating the initial rotation of the engine necessary for ignition. This motor operates using compressed air, which is a common method in large diesel engines found in marine and industrial applications.

Interaction with Engine Components

-

Motor: The Air Starting Motor is directly connected to the engine’s motor. When activated, it uses the force generated by compressed air to turn the motor, initiating the engine’s startup sequence. This interaction ensures that the motor reaches the necessary rotational speed for the fuel injection and combustion processes to begin.

-

Starting System: Within the starting system, the Air Starting Motor works in conjunction with the air reservoir and air distribution valves. The compressed air stored in the reservoir is released into the motor, providing the force needed for engine turnover. The distribution valves regulate the flow of air, ensuring efficient and controlled startup.

-

Ignition System: Once the motor is in motion, the ignition system takes over. The Air Starting Motor’s role diminishes as the engine transitions from air-powered startup to fuel-powered operation. This seamless handover is essential for the engine to achieve stable running conditions.

-

Fuel Injection System: As the engine starts, the fuel injection system begins to deliver fuel into the combustion chambers. The initial rotation provided by the Air Starting Motor allows the fuel injection timing to synchronize with the engine’s mechanical movements, ensuring optimal combustion efficiency.

-

Exhaust System: The startup process also engages the exhaust system. As the engine begins to run, exhaust gases are expelled through the exhaust manifold and into the exhaust system. The Air Starting Motor’s efficient initiation of the engine ensures that the exhaust system operates smoothly from the onset.

Conclusion

In summary, the Cummins 4057977 Air Starting Motor plays a significant role in the startup process of engine systems by providing the initial rotational force needed for ignition. Its interaction with various components ensures a smooth transition from startup to stable engine operation. Regular maintenance and proper integration with truck systems are essential for optimal performance and longevity of this motor.

-

Alma Hillier, Fundamentals of Motor Vehicle Technology Book 1 6th Edition, Oxford University Press, 2014.

↩ -

Haoran Hu, Simon J Baseley and Xubin Song, Advanced Hybrid Powertrains for Commercial Vehicles Second Edition, SAE International, 2021.

↩ -

Saiful Bari, Diesel Engine Combustion, Emissions and Condition Monitoring, InTech, 2013.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.