This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

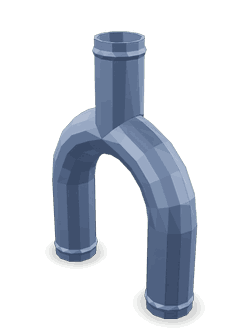

The Cummins 4016359 Air Tube is a component designed for use in commercial trucks, playing a role in the pneumatic system. Its purpose is to facilitate the distribution of compressed air, which is vital for various truck operations, including braking, suspension, and other pneumatic functions. Understanding the significance of this part is important for maintaining the efficiency and reliability of the truck’s pneumatic system.

Basic Concepts of Air Tubes

Air tubes are conduits used in pneumatic systems to transport compressed air from the compressor to various components that require it. They contribute to the overall operation of a truck by ensuring that air-operated systems receive the necessary air pressure to function correctly. The design and material of these tubes are selected to withstand the pressures and environmental conditions encountered in truck operations 1.

Purpose of the 4016359 Air Tube

This Cummins part is specifically designed to play a role in the pneumatic system of a truck by directing compressed air to different components. It supports the operation of air brakes, suspension systems, and other pneumatic accessories by providing a reliable pathway for air distribution. This ensures that these systems can operate efficiently and consistently.

Key Features

The 4016359 is constructed from durable materials that are resistant to the pressures and temperatures encountered in truck environments. Its design includes features that enhance its performance and longevity, such as reinforced connections and a smooth interior to minimize air resistance. These characteristics contribute to the tube’s ability to maintain air pressure and flow efficiently.

Benefits

The use of the 4016359 offers several benefits to the truck’s pneumatic system. It contributes to improved efficiency by ensuring that air is delivered to components without significant loss of pressure. Its reliable construction enhances the overall reliability of the pneumatic system, reducing the likelihood of failures. Additionally, the tube’s design may offer performance enhancements by optimizing air flow to critical systems.

Installation

Proper installation of the 4016359 involves several steps to ensure it fits correctly and functions as intended. This includes preparing the installation site, using the appropriate tools to connect the tube to the system, and verifying that all connections are secure. Following best practices during installation helps to prevent issues such as leaks or improper air flow.

Maintenance

Regular maintenance of the 4016359 is important to ensure its ongoing performance and longevity. This includes inspecting the tube for signs of wear or damage, cleaning it to remove any contaminants that could affect air flow, and performing routine checks to ensure all connections remain secure. Adhering to a maintenance schedule helps to identify and address potential issues before they lead to system failures.

Troubleshooting

Common issues with the 4016359 may include leaks, blockages, or damage to the tube itself. Diagnostic steps to identify these problems involve inspecting the tube and its connections, checking for signs of wear or damage, and testing the air flow to ensure it meets the system’s requirements. Suggested solutions or repairs may include replacing damaged sections of the tube, tightening connections, or cleaning the interior to remove obstructions.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a broad product range, Cummins is recognized for its quality and reliability in the commercial truck industry. The company’s commitment to excellence is reflected in its products, including the 4016359, which is designed to meet the demanding requirements of truck operations.

Cummins Engine Air Tube 4016359

The Cummins engine part 4016359, an Air Tube, is a critical component in the air management system of various Cummins engines. This part is integral to ensuring the efficient and reliable operation of the engines by facilitating the proper flow of air into the engine’s intake system.

Application in Cummins Engines

QSK45 CM500

The Air Tube 4016359 is specifically designed to fit seamlessly within the Cummins QSK45 CM500 engine. This engine is known for its robust performance and reliability, often used in heavy-duty applications such as marine and industrial sectors. The air tube plays a crucial role in maintaining the air pressure and quality required for optimal engine performance.

QSK50

Similarly, in the Cummins QSK50 engine, the Air Tube 4016359 is a vital part of the air intake system. This engine is designed for high-power applications and is widely used in marine and power generation industries. The air tube ensures that the engine receives the correct amount of air, which is essential for combustion efficiency and overall engine health.

QSK60

The Air Tube 4016359 also fits into the Cummins QSK60 engine, which is another high-performance engine used in demanding applications. The air tube’s role in this engine is to maintain the integrity of the air intake system, ensuring that the engine operates smoothly and efficiently under various conditions.

Importance of the Air Tube

The Air Tube 4016359 is engineered to withstand the rigors of heavy-duty operations. It is designed to handle high temperatures, pressures, and vibrations, ensuring durability and longevity. Proper installation and maintenance of this air tube are essential to prevent air leaks, which can lead to decreased engine performance and increased fuel consumption.

By ensuring that the air intake system functions correctly, the Air Tube 4016359 contributes to the overall efficiency and reliability of the Cummins engines it is used in.

Role of Part 4016359 Air Tube in Engine Systems

The 4016359 Air Tube is an essential component in managing and directing airflow within various engine systems. Its functionality is integral to the efficient operation of several key components.

Integration with Blowby Sensor Kit

In conjunction with the blowby sensor kit, the 4016359 Air Tube facilitates the monitoring and regulation of blowby gases. These gases, consisting of unburnt fuel, combustion byproducts, and air, escape past the piston rings into the crankcase. The air tube ensures that these gases are accurately channeled to the sensor, allowing for precise measurement and subsequent management. This helps in maintaining optimal engine performance and reducing emissions.

Collaboration with Breather System

The breather system is designed to ventilate the crankcase by allowing fresh air in and expelling contaminated air out. The 4016359 Air Tube plays a significant role in this process by providing a dedicated pathway for air circulation. It ensures that the breather can effectively manage pressure within the crankcase, preventing the buildup of harmful gases and moisture. This contributes to the longevity and reliability of the engine by reducing the risk of sludge formation and component corrosion.

Support for Crankcase Ventilation

Efficient crankcase ventilation is vital for engine health, and the 4016359 Air Tube is a key player in this system. By connecting various ventilation points within the crankcase, it ensures that air flows smoothly and contaminants are expelled efficiently. This not only helps in maintaining a clean crankcase environment but also supports the overall lubrication system by preventing the dilution of engine oil with blowby gases.

Conclusion

In summary, the 4016359 Air Tube is a fundamental component that enhances the functionality of the blowby sensor kit, breather system, and crankcase ventilation, contributing to the engine’s performance, durability, and environmental compliance.

-

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.