This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

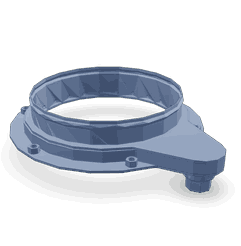

The Cummins 4015492 Air Fuel Mixer is a component designed to enhance the operation of commercial trucks by optimizing the air-fuel mixture within the engine. This part is integral to the engine system, ensuring that the combustion process is efficient and effective. Its role is significant in maintaining the performance and reliability of heavy-duty trucks, which are vital for various commercial applications.

Basic Concepts of Air Fuel Mixers

An air fuel mixer is a device that combines air and fuel in the correct proportions before the mixture enters the combustion chamber of an engine. This process is fundamental to the efficient operation of an internal combustion engine. The air-fuel ratio management is crucial for achieving optimal combustion, which directly affects engine performance, fuel efficiency, and emissions. Proper air-fuel mixture ensures that the engine operates within its designed parameters, leading to better overall performance and longevity 1.

Purpose of the Cummins 4015492 Air Fuel Mixer

The Cummins 4015492 Air Fuel Mixer is designed to optimize the combustion efficiency of a truck’s engine by ensuring a precise air-fuel mixture. This component plays a role in the engine system by regulating the amount of air and fuel that enter the combustion chamber, which is vital for consistent and efficient engine operation. By maintaining the correct air-fuel ratio, the mixer contributes to the engine’s ability to perform under various load conditions and driving scenarios 2.

Key Features

The Cummins 4015492 Air Fuel Mixer incorporates several design elements and materials that enhance its functionality and durability. It is constructed using high-quality materials to withstand the harsh conditions within a truck’s engine compartment. The mixer features a robust design that ensures precise control over the air-fuel mixture, contributing to its reliability and performance. Additionally, it may include technological aspects such as advanced metering systems to ensure accuracy in fuel delivery.

Benefits of Using the Cummins 4015492 Air Fuel Mixer

Utilizing the Cummins 4015492 Air Fuel Mixer offers several advantages. It contributes to improved fuel efficiency by ensuring that the engine operates with the optimal air-fuel mixture. This results in better overall engine performance, as the combustion process is more efficient. Additionally, the mixer helps in reducing emissions by promoting cleaner combustion, which is beneficial for environmental compliance and operational costs. The enhanced performance and efficiency also lead to reduced maintenance requirements and longer engine life 3.

Installation and Integration

Proper installation and integration of the Cummins 4015492 Air Fuel Mixer within a truck’s engine system are crucial for its effective operation. Installation guidelines should be followed to ensure that the mixer is correctly positioned and connected to the engine’s air and fuel systems. Prerequisites may include ensuring that the engine is clean and free of debris, and that all connections are secure and properly sealed. Careful integration is necessary to avoid any disruptions in the engine’s operation.

Maintenance and Care

Routine maintenance and care of the Cummins 4015492 Air Fuel Mixer are important for ensuring its longevity and optimal performance. Regular cleaning of the mixer and its components helps prevent the buildup of contaminants that could affect its operation. Inspections should be conducted to check for any signs of wear or damage, and replacement schedules should be adhered to for components that show signs of deterioration. Proper maintenance ensures that the mixer continues to function efficiently, contributing to the overall performance of the engine.

Troubleshooting Common Issues

Common problems associated with the Cummins 4015492 Air Fuel Mixer may include issues with the air-fuel mixture, such as lean or rich conditions, which can affect engine performance. Troubleshooting steps may involve checking the mixer’s connections and seals for leaks, inspecting the metering system for accuracy, and ensuring that the mixer is clean and free of debris. Solutions may include cleaning or replacing components as necessary to restore proper function.

Compatibility and Applications

The Cummins 4015492 Air Fuel Mixer is designed for use in specific types of engines and truck models. Its applications are varied, suitable for different driving conditions and commercial uses. Ensuring compatibility with the engine and truck model is important for optimal performance and efficiency. The mixer is engineered to meet the demands of heavy-duty applications, providing reliable operation in a range of environments.

Safety Considerations

When working with the Cummins 4015492 Air Fuel Mixer, it is important to observe safety guidelines and precautions. This includes proper handling during installation and maintenance, ensuring that the engine is turned off and cool before beginning work. Safety equipment should be worn to protect against potential hazards, and all procedures should be conducted in accordance with manufacturer recommendations to ensure safe and effective operation.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s product range includes components and systems that are designed to enhance the performance, efficiency, and reliability of commercial vehicles. Cummins’ commitment to quality and customer satisfaction has made it a trusted name in the industry.

Role of Part 4015492 Air Fuel Mixer in Engine Systems

The Air Fuel Mixer, identified by part number 4015492, is an integral component in the orchestration of engine performance, specifically within the charge air bypass system. This component is designed to precisely blend air and fuel before the mixture enters the combustion chamber, ensuring optimal engine efficiency and performance.

Integration with Charge Air Bypass Plumbing

In the charge air bypass system, the Air Fuel Mixer works in concert with the charge air bypass plumbing to manage the flow of air that bypasses the turbocharger. This system is essential for maintaining engine stability and performance under varying load conditions. The Air Fuel Mixer ensures that the air bypassing the turbocharger is correctly mixed with fuel, preventing any potential issues that could arise from an imbalanced air-fuel ratio.

Function within the Plumbing System

The overall plumbing system of the engine, which includes various hoses, pipes, and connectors, relies on the Air Fuel Mixer to deliver a consistent and precise air-fuel mixture. This mixture is vital for the combustion process, directly influencing engine power output, fuel efficiency, and emissions. The mixer’s role becomes even more pronounced in systems where the air flow is dynamically adjusted, such as during charge air bypass operations.

Contribution to Charge Air Bypass

Specifically, within the charge air bypass mechanism, the Air Fuel Mixer helps in fine-tuning the air-fuel mixture that is reintroduced into the engine’s intake tract. This adjustment is necessary to compensate for the air that has bypassed the turbocharger, ensuring that the engine receives a consistent and optimal air-fuel mixture regardless of the operational conditions. This contributes to smoother engine operation, reduced emissions, and improved fuel economy.

Conclusion

In summary, the Air Fuel Mixer (part 4015492) plays a significant role in enhancing the functionality and efficiency of the charge air bypass system and the overall engine plumbing. Its precise control over the air-fuel mixture is essential for maintaining engine performance across a wide range of operating conditions.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.