This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3970105 Air Fuel Mixer is a component designed to enhance the operation of commercial trucks by optimizing the air-fuel mixture within the engine. This part is integral to ensuring that the engine operates efficiently, contributing to overall vehicle performance and fuel economy 1.

Basic Concepts of Air Fuel Mixers

An air fuel mixer is a device that combines air and fuel in the correct proportions before the mixture enters the engine’s combustion chamber. This process is vital for achieving optimal combustion efficiency, which in turn affects engine performance, emissions, and fuel consumption. The mixer ensures that the air-fuel ratio is consistent, allowing the engine to burn fuel more completely and efficiently 2.

Purpose of the 3970105 Air Fuel Mixer

The 3970105 plays a specific role in the operation of a truck by precisely controlling the air-fuel mixture. This control contributes to improved engine performance and fuel efficiency. By ensuring that the engine receives the optimal air-fuel ratio, the mixer helps to maximize power output while minimizing fuel consumption and emissions 3.

Key Features

This Cummins part is characterized by several key features that enhance its performance. These include a robust design that ensures durability under the demanding conditions of commercial truck operation. The mixer is constructed from high-quality materials to withstand high temperatures and pressures. Additionally, it incorporates advanced technology to maintain precise control over the air-fuel mixture, ensuring consistent engine performance.

Benefits

Using the 3970105 offers several benefits. These include improved fuel economy, as the optimal air-fuel mixture allows the engine to operate more efficiently. Reduced emissions are another advantage, as precise control over the mixture leads to more complete combustion and lower pollutant output. Enhanced engine performance is also a benefit, with the mixer contributing to smoother operation and increased power output.

Installation Process

Installing the 3970105 involves several steps to ensure a successful integration into the engine system. Prerequisites include ensuring that the engine is clean and free of debris. The necessary tools for installation may include wrenches, screwdrivers, and possibly a torque wrench to ensure proper tightening of components. Best practices for installation include following the manufacturer’s instructions carefully, ensuring all connections are secure, and performing a system check to confirm proper operation after installation.

Maintenance Tips

To ensure the longevity and optimal performance of the 3970105, regular maintenance is recommended. This includes periodic inspection intervals to check for signs of wear or damage. Cleaning procedures may involve removing any buildup of carbon or other deposits that could affect performance. Replacement guidelines should be followed to ensure that the mixer is replaced at the appropriate intervals to maintain engine efficiency.

Troubleshooting Common Issues

Common issues that may arise with the 3970105 include inconsistent air-fuel mixture, which can lead to poor engine performance or increased emissions. Troubleshooting steps may involve checking for leaks in the system, ensuring all connections are secure, and verifying that the mixer is functioning correctly. Solutions to these problems may include repairing or replacing damaged components and recalibrating the mixer if necessary.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines, known for its commitment to innovation and quality in the industry. With a history of producing reliable and efficient engine components, Cummins has established a reputation for excellence. The company’s dedication to advancing engine technology ensures that its products, like the 3970105, contribute to the performance and efficiency of commercial trucks.

Role of Part 3970105 Air Fuel Mixer in Engine Systems

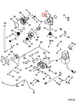

The Air Fuel Mixer, identified by part number 3970105, is integral to the efficient operation of engine systems. It works in conjunction with several key components to ensure optimal performance.

Integration with the Module

The Air Fuel Mixer interfaces directly with the engine module. This module typically houses the electronic control unit (ECU) which regulates various engine functions. The mixer provides a precise blend of air and fuel, which is essential for the ECU to maintain the correct air-fuel ratio. This ratio is vital for combustion efficiency, power output, and emissions control. The module relies on feedback from various sensors to adjust the mixture delivered by the Air Fuel Mixer, ensuring that the engine operates within specified parameters.

Coordination with the Fuel Control System

In tandem with the fuel control system, the Air Fuel Mixer plays a significant role in delivering the appropriate fuel-air mixture to the combustion chamber. The fuel control system, which may include components like fuel injectors and pressure regulators, works in harmony with the mixer to achieve the desired fuel delivery rate. The Air Fuel Mixer ensures that the air and fuel are thoroughly mixed before entering the combustion chamber, which is essential for complete and efficient combustion. This coordination helps in maintaining engine performance across different operating conditions, from idle to full throttle.

Conclusion

The Cummins 3970105 Air Fuel Mixer is a critical component for enhancing the efficiency and performance of commercial truck engines. By ensuring an optimal air-fuel mixture, this part contributes to improved fuel economy, reduced emissions, and enhanced engine performance. Proper installation, regular maintenance, and timely troubleshooting are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.