This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

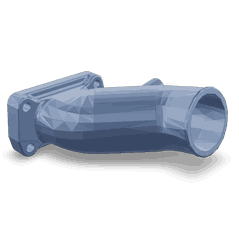

The Air Crossover Connector, identified by part number 3933289, is a component manufactured by Cummins, a prominent entity in the commercial truck industry. This connector is integral to the air system of heavy-duty trucks, facilitating the distribution of compressed air to various components. Cummins is renowned for its high-quality parts and systems, and the Air Crossover Connector is no exception, designed to enhance the efficiency and reliability of truck air systems 1.

Function and Operation

The Air Crossover Connector operates within the truck’s air system by directing compressed air from the compressor to different parts of the vehicle that require it. This includes the brakes, suspension systems, and other pneumatic components. The connector ensures that air is evenly distributed, which is vital for the consistent performance of these systems. It acts as a junction point, allowing air to flow to multiple destinations from a single source 2.

Purpose of the Air Crossover Connector

The primary role of the Air Crossover Connector in a truck’s operation is to maintain efficient air distribution. By ensuring that compressed air reaches all necessary components without loss or delay, it contributes to the overall effectiveness of the truck’s air-operated systems. This is particularly important in heavy-duty trucks, where reliable air supply is crucial for safety and performance 3.

Key Features

The Air Crossover Connector is constructed from durable materials, designed to withstand the high pressures and temperatures of a truck’s air system. Its design includes features that enhance its performance, such as precise fittings to ensure a secure connection and minimize air leaks. Additionally, the connector is engineered to be compatible with a wide range of truck models, making it a versatile component in the industry.

Benefits

The advantages of using the Air Crossover Connector include improved efficiency in the air system, enhanced durability under demanding conditions, and increased reliability. These benefits contribute to the overall performance and longevity of the truck, reducing the need for frequent repairs and maintenance.

Installation Considerations

When installing the Air Crossover Connector, it is important to follow guidelines to ensure proper fit and function. This may involve preparatory steps such as cleaning the installation area and checking for compatibility with the truck’s existing air system. Using the appropriate tools and following manufacturer recommendations can help ensure a successful installation.

Common Issues and Troubleshooting

Typical problems with the Air Crossover Connector may include air leaks, connection failures, or damage from wear and tear. Troubleshooting these issues often involves inspecting the connector for signs of wear, ensuring all connections are secure, and replacing any damaged parts. Regular maintenance can help prevent these issues from arising.

Maintenance Tips

To maintain the Air Crossover Connector and ensure optimal performance, regular inspection and cleaning are recommended. This includes checking for signs of wear or damage, ensuring all connections are tight, and cleaning the connector to remove any debris that could affect its operation. Following these maintenance tips can help extend the life of the connector and maintain the efficiency of the truck’s air system.

Cummins Overview

Cummins, the manufacturer of the Air Crossover Connector, has a long-standing reputation in the commercial truck industry. With a history of innovation and quality, Cummins offers a wide range of products designed to enhance the performance and reliability of trucks. Their commitment to excellence is evident in the design and construction of their parts, including the Air Crossover Connector.

Compatibility with Cummins Engines

The Air Crossover Connector 3933289 is specifically engineered to fit seamlessly with various Cummins engine models, including but not limited to:

- 6B5.9 Series: This part is integral to the 6B5.9 engine series, where it connects the intake manifold to the turbocharger, enhancing the efficiency of the air intake process.

The design of the 3933289 ensures that it can withstand the high temperatures and pressures typical in engine environments, providing a durable and reliable connection that minimizes air leaks and maximizes engine efficiency.

Installation and Maintenance

Proper installation of the Air Crossover Connector 3933289 is crucial for maintaining the integrity of the engine’s air intake system. Regular inspection and maintenance of this part can help prevent potential issues such as air leaks, which can negatively impact engine performance and fuel efficiency.

Performance Benefits

By ensuring a consistent and unobstructed flow of air, the Air Crossover Connector 3933289 contributes to improved engine performance, better fuel economy, and reduced emissions. This makes it an essential component for those seeking to maintain the optimal operation of their Cummins engines.

Role of Part 3933289 Air Crossover Connector in Engine Systems

The Air Crossover Connector, identified by part number 3933289, is an integral component in the efficient operation of engine systems, particularly in configurations involving turbochargers. This connector facilitates the seamless transfer of air between various components, enhancing overall engine performance and reliability.

Integration with Turbocharger Arrangement

In a turbocharger arrangement, the Air Crossover Connector plays a significant role by linking the intake manifolds of the engine. This connection allows for the balanced distribution of air to each turbocharger, ensuring that both sides of the engine receive an equal amount of airflow. This balance is essential for maintaining optimal turbocharger performance and preventing issues such as turbo lag or uneven boost pressure.

Enhancing Turbocharger Efficiency

By providing a direct pathway for air to travel between the turbochargers, the Air Crossover Connector helps in reducing pressure differentials. This reduction ensures that each turbocharger operates within its designed parameters, leading to improved efficiency and responsiveness. The connector also aids in smoothing out the airflow, which can contribute to a more stable and consistent power delivery.

Contribution to Overall Engine Arrangement

In the broader context of the engine arrangement, the Air Crossover Connector supports the integration of various components. It works in conjunction with the intake manifolds, intercoolers, and other air management systems to create a cohesive and efficient air flow path. This integration is vital for maximizing the engine’s potential, especially in high-performance applications where every aspect of air management can significantly impact output and reliability.

Summary of Component Interaction

- Intake Manifolds: The connector ensures uniform air distribution to each manifold, promoting balanced engine operation.

- Turbochargers: It equalizes air pressure between turbochargers, enhancing their efficiency and performance.

- Intercoolers: By maintaining consistent airflow, the connector supports the effective cooling of air before it enters the combustion chambers.

- Air Management Systems: It integrates seamlessly with other air management components, contributing to overall system efficiency.

Conclusion

The Air Crossover Connector, part 3933289, is a key element in the intricate network of components that make up modern engine systems. Its role in facilitating balanced and efficient air flow is fundamental to the performance and reliability of turbocharged engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.