This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

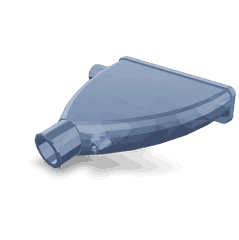

The Air Crossover Connection, identified by Part #3931998, is a component integral to the operation of commercial trucks. It facilitates the distribution of air pressure between different brake circuits, ensuring balanced and efficient braking performance. Cummins Inc., a renowned manufacturer in the diesel engine and related components industry, produces this part. With a rich history of innovation and a broad product range, Cummins is recognized for its commitment to quality and reliability in the automotive sector 1.

Basic Concepts of Air Crossover Connection

Air crossover connections are fundamental components in pneumatic systems, particularly within the air brake systems of trucks. They enable the transfer of compressed air between separate brake circuits, which is vital for maintaining balanced braking force across all wheels. This balance is crucial for the safe and effective operation of the vehicle, especially under varying load conditions and driving scenarios 2.

Purpose of the Air Crossover Connection

The Air Crossover Connection serves a pivotal role in the operation of a truck by ensuring that air pressure is evenly distributed between different brake circuits. This even distribution is necessary for the synchronized activation of brakes across all wheels, which enhances the vehicle’s stopping power and stability. By facilitating this balanced air pressure, the component contributes to the overall safety and performance of the truck’s braking system 3.

Key Features of the Cummins Air Crossover Connection

The Cummins Air Crossover Connection is designed with specific features that enhance its performance and durability. It is constructed from high-quality materials that resist corrosion and wear, ensuring longevity in demanding environments. The design includes precise fittings and connections that minimize air leakage, thereby maintaining optimal air pressure within the brake system. Additionally, the component is engineered to withstand high pressures and temperatures, making it suitable for heavy-duty applications.

Benefits of Using the Cummins Air Crossover Connection

Utilizing the Cummins Air Crossover Connection offers several advantages. It contributes to improved brake system reliability by ensuring consistent air pressure distribution. This reliability enhances safety, as it reduces the risk of brake failure during operation. Furthermore, the component’s durable construction and efficient design can lead to potential cost savings through reduced maintenance needs and extended service life.

Installation and Integration

Proper installation and integration of the Cummins Air Crossover Connection within a truck’s existing brake system are vital for ensuring compatibility and optimal performance. It is important to follow manufacturer guidelines for installation, which may include specific torque settings for fittings and connections. Ensuring that the component is correctly aligned and securely fastened will help maintain the integrity of the brake system and prevent air leaks.

Troubleshooting and Maintenance

Common issues with air crossover connections may include air leaks, blockages, or corrosion. Regular inspection and maintenance can help identify and address these issues before they lead to more significant problems. Maintenance practices should include checking for signs of wear or damage, ensuring all connections are tight, and cleaning the component to prevent corrosion. Promptly addressing any issues will help prolong the lifespan and ensure the continued efficient operation of the Air Crossover Connection.

Safety Considerations

When working with air crossover connections and the pneumatic brake system, it is important to observe several safety practices and precautions. This includes ensuring the system is depressurized before performing any maintenance or repairs to prevent injury from released air pressure. Additionally, using the correct tools and following manufacturer guidelines for installation and maintenance will help ensure the safe and effective operation of the brake system.

Cummins: A Brief Overview

Cummins Inc. is a global leader in the design, manufacture, and distribution of diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established itself as a pioneer in the industry, known for its innovative products and commitment to sustainability. The company’s extensive product range includes engines, filtration systems, emissions solutions, and power generation equipment, serving a wide array of industries and applications. Cummins’ dedication to quality, performance, and customer satisfaction underscores its position as a trusted partner in the automotive and heavy-duty truck sectors.

Cummins Air Crossover Connection 3931998

The Cummins Air Crossover Connection part number 3931998 is a critical component in the air intake system of certain Cummins engines. This part is designed to facilitate the smooth and efficient transfer of air between different sections of the engine’s intake manifold. Its primary function is to ensure that the air is evenly distributed, which is essential for maintaining optimal engine performance and efficiency.

Compatibility with Cummins Engines

The Air Crossover Connection 3931998 is specifically engineered to fit seamlessly with several Cummins engine models. These include, but are not limited to:

- 4B3.9: This engine model benefits from the precise air management capabilities of the 3931998 part, ensuring that the air intake is balanced and consistent, which helps in achieving better combustion efficiency.

Importance in Engine Performance

In Cummins engines, the air crossover connection plays a vital role in the overall air management system. By ensuring that the air is evenly distributed, this part helps in:

- Enhancing Combustion Efficiency: Proper air distribution leads to more complete combustion, which can improve fuel efficiency and reduce emissions.

- Maintaining Engine Stability: Consistent air flow helps in maintaining stable engine operation, which is crucial for performance and longevity.

- Reducing Stress on Components: Even air distribution reduces the stress on various engine components, potentially extending their lifespan.

Installation and Maintenance

When installing the Cummins Air Crossover Connection 3931998, it is important to follow the manufacturer’s guidelines to ensure a proper fit and function. Regular maintenance checks should be performed to verify that the part is in good condition and is not obstructed or damaged, as this can affect engine performance.

By integrating this part into the engine’s air intake system, Cummins ensures that the engine operates at its best, providing reliable and efficient performance across various applications.

Role of Part 3931998 Air Crossover Connection in Engine Systems

The 3931998 Air Crossover Connection is an essential component in the arrangement of certain engine systems, particularly those equipped with turbochargers. This part facilitates the efficient distribution of air between the turbochargers in a twin-turbo setup, ensuring balanced airflow and optimal performance.

In a twin-turbo configuration, the Air Crossover Connection plays a significant role by linking the intake tracts of the two turbochargers. This connection allows the air compressed by one turbocharger to be directed to the other, promoting a more uniform distribution of air across the engine’s cylinders. This balanced airflow is vital for maintaining consistent power delivery and reducing the likelihood of uneven cylinder performance.

Additionally, the placement of the turbochargers can influence the design and routing of the Air Crossover Connection. In setups where turbochargers are located on opposite sides of the engine, this component ensures that air can travel efficiently between them, minimizing pressure drops and enhancing overall system efficiency.

The Air Crossover Connection also contributes to the thermal management of the engine system. By allowing hot air from one turbocharger to be mixed with cooler air from the other, it helps in reducing the temperature of the intake charge. This can lead to improved combustion efficiency and reduced thermal stress on engine components.

In summary, the 3931998 Air Crossover Connection is a key element in the arrangement of twin-turbo engine systems, playing a vital role in airflow management, performance optimization, and thermal regulation.

Conclusion

The Cummins Air Crossover Connection, part number 3931998, is a critical component in both the braking and engine systems of commercial trucks and heavy-duty engines. Its role in ensuring balanced air pressure distribution enhances the safety, performance, and efficiency of these systems. Proper installation, regular maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

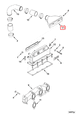

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.