3928502

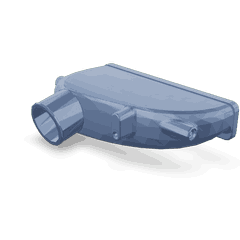

Air Crossover Connection

Cummins®

AVAILABLE

2 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Air Crossover Connection 3928502 is a component designed by Cummins for use in heavy-duty trucks. It serves a specific function within the truck’s air brake system, contributing to the overall efficiency and reliability of the vehicle’s braking capabilities. This part is integral to the operation of the air brake system, ensuring that air is distributed evenly and efficiently throughout the system.

Basic Concepts of Air Crossover Connections

An air crossover connection is a component that facilitates the transfer of compressed air between different sections of a truck’s air brake system. It plays a role in maintaining balanced air pressure across the system, which is vital for consistent brake performance. By allowing air to flow between different parts of the system, it helps ensure that each brake component receives the necessary air pressure to function correctly 1.

Purpose of the 3928502 Air Crossover Connection

The 3928502 Air Crossover Connection is designed to enhance the distribution of air within the truck’s air brake system. It connects various components, allowing for a more uniform distribution of air pressure. This connection helps maintain system efficiency by ensuring that all parts of the brake system operate under optimal conditions. It contributes to the overall reliability of the air brake system by facilitating balanced air pressure 2.

Key Features

The 3928502 Air Crossover Connection is characterized by its robust design and the quality materials used in its construction. It is engineered to withstand the demanding conditions of heavy-duty truck operations. The connection features a durable construction that enhances its performance and longevity. Its design allows for easy integration into the existing air brake system, ensuring a seamless fit and function.

Benefits

The use of the 3928502 Air Crossover Connection offers several advantages. It contributes to improved air system reliability by ensuring balanced air pressure throughout the system. This balanced pressure leads to enhanced brake performance, providing more consistent and reliable braking under various conditions. Additionally, by optimizing air distribution, it may contribute to fuel efficiency, as the truck’s engine does not have to work as hard to maintain the necessary air pressure for the brake system 3.

Installation Considerations

When installing the 3928502 Air Crossover Connection, it is important to follow guidelines and best practices to ensure proper integration into the truck’s air brake system. Preparatory steps may include ensuring the system is clean and free of debris, and that all connections are secure. The use of appropriate tools is recommended to facilitate a smooth installation process. It is also advisable to avoid common pitfalls, such as over-tightening connections, which can lead to damage.

Troubleshooting Common Issues

Frequent problems associated with air crossover connections can include leaks, blockages, or improper installation. Diagnostic steps for troubleshooting may involve checking for visible signs of damage or wear, testing for leaks using a pressure gauge, and ensuring all connections are secure. Recommended solutions or repairs may include replacing damaged components, cleaning or replacing filters, or adjusting connections to ensure proper fit and function.

Maintenance Tips

Routine maintenance of the 3928502 Air Crossover Connection is recommended to ensure its longevity and optimal performance. This may include regular inspection intervals to check for signs of wear or damage, and cleaning procedures to remove any debris or contaminants that may affect its function. Proper maintenance helps ensure the connection continues to contribute to the efficiency and reliability of the truck’s air brake system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s commitment to quality and innovation is evident in its wide range of products, designed to meet the demanding needs of heavy-duty applications.

Cummins Air Crossover Connection Part 3928502

The Cummins Air Crossover Connection part number 3928502 is a critical component in the air management system of various Cummins engines. This part is designed to facilitate the efficient transfer of air between different sections of the engine’s intake system, ensuring optimal performance and reliability.

Application in Cummins Engines

-

6B5.9 Engine Family: The 6B5.9 engine series, known for its robust design and high performance, utilizes the 3928502 Air Crossover Connection to manage the air flow. This part is integral in maintaining the balance and pressure required for the engine’s operation, particularly in heavy-duty applications where consistent power output is crucial.

-

Group Applications: The 3928502 Air Crossover Connection is also compatible with other Cummins engine groups that share similar design principles and air management requirements. This ensures that the part can be effectively used across a range of engine models, providing a standardized solution for air crossover needs.

By integrating seamlessly into the engine’s air management system, the 3928502 Air Crossover Connection helps to maintain the engine’s efficiency and longevity, making it a vital component for Cummins engine users.

Role of Part 3928502 Air Crossover Connection in Engine Systems

The Air Crossover Connection (Part 3928502) is an integral component in the orchestration of airflow within engine systems, particularly those equipped with turbochargers. Its primary function is to facilitate the seamless transfer of air between the turbocharger and the intake manifold, ensuring optimal air distribution to the engine’s cylinders.

Integration with Turbocharger and Manifold

In turbocharged engine setups, the Air Crossover Connection acts as a bridge between the turbocharger and the intake manifold. Post-compression by the turbocharger, air is directed through this connection to the manifold. This ensures that the pressurized air is evenly distributed across all cylinders, enhancing combustion efficiency and power output.

Interaction with Exhaust and Turbocharger Location

The effectiveness of the Air Crossover Connection is also influenced by the exhaust system and the location of the turbocharger(s). In systems with twin turbochargers, for instance, the Air Crossover Connection plays a pivotal role in balancing the air supply from each turbocharger to the manifold. This balance is essential for maintaining engine performance and reducing the risk of uneven cylinder fueling, which can lead to decreased efficiency and potential engine damage.

Arrangement and Airflow Management

The arrangement of the Air Crossover Connection within the engine bay is designed to minimize turbulence and maximize airflow efficiency. Its placement is strategically chosen to reduce the distance air travels from the turbocharger to the manifold, thereby minimizing pressure loss and ensuring that the air reaches the cylinders at the optimal pressure and temperature.

Conclusion

In summary, the Air Crossover Connection (Part 3928502) is a key component in the airflow management of turbocharged engine systems. Its role in connecting the turbocharger to the intake manifold, interacting with the exhaust system, and contributing to the overall arrangement of engine components underscores its importance in achieving efficient and powerful engine performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.