This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

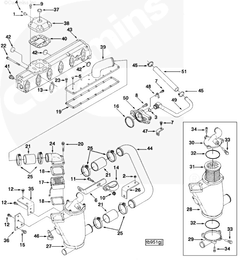

Understanding The Cummins 3918310 Air Crossover Connection

Introduction to Air Crossover Connections

Air crossover connections are essential components in the air management systems of commercial trucks. These parts facilitate the efficient distribution of compressed air throughout the engine, ensuring optimal performance and reliability. Understanding the role and functionality of an air crossover connection is crucial for engineers, mechanics, and fleet operators 1.

The Role of Cummins 3918310 Air Crossover Connection

The Cummins 3918310 Air Crossover Connection is specifically designed to manage the airflow within the engine’s air management system. This part ensures that air is evenly distributed to various components, enhancing the engine’s efficiency and performance. By maintaining a consistent air supply, the 3918310 Air Crossover Connection helps in reducing wear and tear, thereby extending the lifespan of the engine 2.

How the Cummins 3918310 Air Crossover Connection Works

The Cummins 3918310 Air Crossover Connection operates by connecting different sections of the air management system. It allows for the redirection of air from one part of the engine to another, ensuring that all components receive the necessary air pressure. This seamless transition is critical for maintaining the engine’s balance and preventing potential air restrictions that could lead to performance issues 3.

Importance in Truck Operations

In the context of truck operations, the 3918310 Air Crossover Connection plays a pivotal role. It ensures that the engine operates at peak efficiency, which is essential for long-haul trucking and heavy-duty applications. By maintaining optimal air pressure, this part contributes to better fuel economy, reduced emissions, and enhanced overall performance.

Troubleshooting and Maintenance

Regular maintenance of the 3918310 Air Crossover Connection is vital to ensure its longevity and effectiveness. Mechanics should inspect the part for any signs of wear, corrosion, or blockages. If any issues are detected, prompt repairs or replacements should be carried out to prevent potential engine problems.

- Inspection: Regularly check for leaks, cracks, or any obstructions in the air pathways.

- Cleaning: Ensure that the air crossover connection is free from dirt and debris that could impede airflow.

- Repairs: Address any damage immediately to maintain the integrity of the air management system.

Cummins: A Leader in Engine Technology

Cummins is a renowned manufacturer of high-quality engine components, known for its innovation and reliability. The Cummins 3918310 Air Crossover Connection is a testament to the company’s commitment to providing durable and efficient parts for commercial trucks. Cummins’ extensive experience in the industry ensures that their products meet the highest standards of performance and durability.

Application in Specific Engines

-

6B5.9 Engine Family:

- The 6B5.9 engine series, known for its robust performance and reliability, utilizes the 3918310 Air Crossover Connection to maintain efficient air management. This part is integral in ensuring that the engine operates smoothly by connecting the air intake pathways, which helps in balancing the air pressure and flow.

-

Other Cummins Engines:

- Beyond the 6B5.9, the 3918310 Air Crossover Connection is also compatible with other Cummins engine models. Its design allows it to fit seamlessly into the air management systems of these engines, providing a reliable connection that supports the engine’s overall performance and efficiency.

Importance in Engine Performance

The proper functioning of the Air Crossover Connection is essential for maintaining the engine’s performance. It ensures that the air intake is evenly distributed, which is crucial for combustion efficiency and power output. Any malfunction or wear in this part can lead to uneven air distribution, potentially causing performance issues and reduced engine efficiency.

Compatibility and Installation

When installing the 3918310 Air Crossover Connection, it is important to ensure that it is correctly aligned and securely fastened. This part is designed to fit snugly within the engine’s air management system, providing a stable and reliable connection that can withstand the operational stresses of the engine. Proper installation is key to maintaining the integrity of the air pathways and ensuring the engine runs at peak performance.

Integration with Turbocharger and Turbocharger Location

In engines with twin turbochargers, the Air Crossover Connection plays a significant role in harmonizing the airflow from both turbochargers. It ensures that the air pressure is evenly distributed, preventing any one turbocharger from overworking while the other remains underutilized. This balanced airflow is essential for maintaining consistent boost levels and preventing uneven wear on the turbochargers.

The location of the turbochargers is also a consideration. In engines where turbochargers are positioned on opposite sides, the Air Crossover Connection acts as a bridge, allowing air to flow seamlessly from one side to the other. This is particularly important in high-performance engines where precise air management is key to achieving maximum power output and efficiency.

Interaction with Aftercooler

The Air Crossover Connection is also vital in the arrangement involving an aftercooler. After the compressed air leaves the turbochargers, it is often routed through an aftercooler to reduce its temperature before entering the engine’s combustion chambers. The Air Crossover Connection ensures that the cooled air is evenly distributed, which is essential for efficient combustion and reducing the risk of detonation.

Conclusion

The Cummins 3918310 Air Crossover Connection is a critical component in the air management system of commercial trucks. Its role in ensuring efficient airflow and optimal engine performance cannot be overstated. By understanding its function, importance, and maintenance requirements, engineers, mechanics, and fleet operators can ensure the longevity and reliability of their trucks. Cummins’ reputation for quality and innovation further underscores the value of this part in the industry.

-

Handbook of Diesel Engines, Klaus Mollenhauer, Helmut Tschoeke

↩ -

Proceedings of the 5th Commercial Vehicle Technology Symposium CVT 2018, Karsten Berns, Klaus Dressler, Patrick Fleischmann, Daniel Grges, Ralf Kalmar, Bernd Sauer, Nicole Stephan, Roman Teutsch, Martin Thul

↩ -

The Complete Vehicle, Michael Trzesniowski

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.