This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3609930 Filter Screen is a component designed to enhance the operational efficiency of commercial trucks. Its primary role is to filter out contaminants from the fuel system, ensuring that only clean fuel reaches the engine. This contributes to maintaining engine performance and longevity 1.

Basic Concepts of Filter Screens

Filter screens are devices used in mechanical systems to remove impurities from fluids or gases. They operate by allowing the fluid to pass through a mesh or perforated material while trapping particles that could cause damage or reduce efficiency. In mechanical systems, filter screens play a role in protecting sensitive components from wear and tear caused by contaminants 2.

Purpose of the Cummins 3609930 Filter Screen

The Cummins 3609930 Filter Screen is specifically designed to filter contaminants from the fuel system of trucks. It is part of the fuel filtration system and helps to remove particles that could otherwise clog fuel injectors or damage the engine. By ensuring that the fuel is clean, the filter screen contributes to the efficient operation of the engine and helps to maintain its performance over time 3.

Key Features

The Cummins 3609930 Filter Screen is constructed from durable materials that can withstand the harsh conditions of the fuel system. Its design includes a fine mesh that effectively traps small particles while allowing fuel to flow freely. Additionally, the filter screen is engineered to be easy to install and replace, which simplifies maintenance procedures.

Benefits of Using the 3609930 Filter Screen

Incorporating the Cummins 3609930 Filter Screen into truck maintenance routines offers several advantages. It contributes to improved engine performance by ensuring that clean fuel is delivered to the engine. This can lead to better fuel efficiency and reduced emissions. Additionally, the filter screen helps to extend the longevity of engine components by preventing damage from contaminants. Overall, it enhances the efficiency of the fuel system 4.

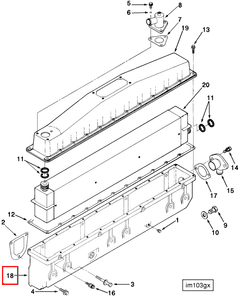

Installation and Replacement Guidelines

To install or replace the Cummins 3609930 Filter Screen, begin by ensuring the truck is turned off and the fuel system is depressurized. Locate the filter screen within the fuel system and remove any retaining clips or bolts. Carefully take out the old filter screen and inspect it for signs of damage or clogging. Install the new filter screen by reversing the removal process, ensuring it is securely in place. Finally, repressurize the fuel system and check for leaks before starting the engine 5.

Troubleshooting Common Issues

Common issues with filter screens may include reduced fuel flow or engine performance. These problems can arise from a clogged filter screen, which may be caused by contaminated fuel or infrequent maintenance. To address these issues, inspect the filter screen for signs of clogging and replace it if necessary. Additionally, ensure that the fuel being used is of high quality and free from contaminants.

Maintenance Tips

To ensure the longevity and effectiveness of the Cummins 3609930 Filter Screen, regular maintenance is recommended. This includes inspecting the filter screen during routine maintenance checks and replacing it according to the manufacturer’s guidelines. Additionally, cleaning the filter screen as part of regular maintenance can help to extend its lifespan and ensure optimal performance.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company offers a wide range of products designed to meet the needs of various applications, from on-highway to off-highway and industrial uses. Cummins is known for its commitment to customer satisfaction and its focus on developing technologies that improve efficiency and reduce environmental impact 6.

Cummins Filter Screen Part 3609930 Compatibility

The Cummins Filter Screen part number 3609930 is designed to fit seamlessly with several engine models, ensuring optimal filtration and performance. This part is crucial for maintaining the integrity of the engine’s fuel and lubrication systems by preventing contaminants from entering sensitive components.

G855 and NH/NT 855 Engines

The Filter Screen part 3609930 is compatible with the G855 and NH/NT 855 engines. These engines are known for their robust design and reliability, often used in heavy-duty applications. The filter screen ensures that the fuel and lubrication systems remain clean, which is vital for the longevity and efficiency of these engines.

N14 MECHANICAL Engine

The N14 MECHANICAL engine also benefits from the use of the Cummins Filter Screen part 3609930. This engine is renowned for its durability and power, frequently utilized in various industrial and transportation sectors. The filter screen plays a critical role in maintaining the engine’s performance by filtering out impurities that could otherwise cause wear and tear.

Installation and Maintenance

Proper installation of the Cummins Filter Screen part 3609930 is essential to ensure it functions effectively. Regular maintenance checks should be performed to verify that the filter screen is in good condition and not clogged, which could impede the flow of fuel or lubricants. Replacement should be done according to the manufacturer’s recommendations to maintain the engine’s performance and reliability.

Role of Part 3609930 Filter Screen in Engine Systems

The part 3609930 Filter Screen is an essential component in maintaining the efficiency and longevity of various engine systems. Its primary function is to trap contaminants and debris, ensuring that only clean fluid or air passes through critical components.

In the aftercooler and air aftercooler systems, the filter screen prevents particulate matter from entering the cooling passages. This ensures optimal cooling efficiency and protects the sensitive components within the aftercooler.

For the air intake intercooler and air intercooler, the filter screen is positioned to catch impurities from the incoming air. This clean air is vital for effective intercooling, which in turn enhances the overall performance and reliability of the engine.

In the air intake manifold and intake manifold, the filter screen plays a significant role by filtering the air before it mixes with fuel. This results in a cleaner combustion process, reducing the risk of deposits and improving engine efficiency.

The air intake manifold assembly and manifold air intake also benefit from the filter screen by ensuring that the air entering the system is free from contaminants. This contributes to consistent engine performance and reduces the likelihood of wear on internal components.

For the turbocharger and turbo systems, the filter screen is integral in protecting the turbocharger from ingesting foreign particles. This protection is essential for maintaining the turbocharger’s efficiency and extending its operational life.

In the plumbing aftercooler water system, the filter screen ensures that the water used for cooling is free from impurities. This is important for maintaining the thermal efficiency of the aftercooler and preventing corrosion within the system.

Overall, the part 3609930 Filter Screen is a vital component in various engine systems, contributing to their efficient operation and durability by ensuring that only clean fluids and air are circulated through critical components.

Conclusion

The Cummins 3609930 Filter Screen plays a crucial role in maintaining the efficiency and longevity of commercial truck engines. By filtering out contaminants from the fuel system, it ensures that only clean fuel reaches the engine, contributing to improved performance and reduced emissions. Regular maintenance and proper installation are essential to maximize the benefits of this Cummins part.

-

Reif, K. (2015). Gasoline Engine Management Systems and Components. Springer Vieweg.

↩ -

Parikyan, T. (Ed.). (2022). Advances in Engine and Powertrain Research and Technology. Springer Nature.

↩ -

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4332668.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4332668.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.