This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Air Fuel Throttle Valve 3607696, manufactured by Cummins, is a critical component in the engine systems of commercial trucks. This valve is essential for managing the air-fuel mixture within diesel engines, ensuring optimal performance and efficiency.

Basic Concepts of Air Fuel Throttle Valves

Air fuel throttle valves are engineered to regulate the mixture of air and fuel entering the engine. In diesel engines, precise control of this mixture is crucial for efficient combustion, directly impacting engine performance and emissions. The valve modulates airflow to ensure the correct amount of air is available for the fuel being injected, optimizing the combustion process 1.

Operation of the Air Fuel Throttle Valve 3607696

The Air Fuel Throttle Valve 3607696 adjusts the airflow into the engine in response to signals from the engine control unit (ECU). It works in conjunction with other engine components, such as fuel injectors and sensors, to maintain the desired air-fuel ratio. This interaction ensures the engine runs smoothly under various operating conditions, from idle to full load 2.

Role in Truck Operation

In commercial trucks, the Air Fuel Throttle Valve 3607696 ensures the engine operates efficiently by regulating the air-fuel mixture. This contributes to better fuel efficiency, reduced emissions, and enhanced engine performance, which is particularly important in heavy-duty applications where efficiency and reliability are paramount 3.

Key Features

The Air Fuel Throttle Valve 3607696 is characterized by several key features that enhance its functionality and durability. Its design incorporates high-quality materials that resist wear and corrosion, ensuring long-term reliability. Technological advancements in its construction allow for precise control of the air-fuel mixture, contributing to improved engine performance and fuel efficiency.

Benefits

The benefits of the Air Fuel Throttle Valve 3607696 include improved engine performance through precise air-fuel mixture control, enhanced fuel efficiency leading to cost savings, and better emissions control contributing to environmental sustainability. These advantages make it a valuable component in the engine system of commercial trucks.

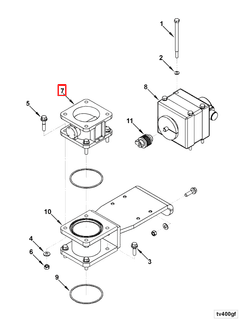

Installation Process

Installing the Air Fuel Throttle Valve 3607696 involves several steps. First, the old valve, if present, is removed. The new valve is then positioned and secured in place, ensuring all connections are tight and secure. It is important to follow the manufacturer’s guidelines for installation to ensure proper function and compatibility with the engine system.

Troubleshooting Common Issues

Common issues with the Air Fuel Throttle Valve 3607696 may include malfunctions due to wear, electrical faults, or contamination. Troubleshooting involves checking for physical damage, ensuring electrical connections are secure, and cleaning or replacing the valve if necessary. Regular maintenance can prevent many of these issues.

Maintenance Tips

To ensure the longevity and optimal performance of the Air Fuel Throttle Valve 3607696, regular maintenance is recommended. This includes periodic inspections for wear or damage, cleaning the valve to remove any contaminants, and ensuring all electrical connections are secure. Following these maintenance tips can help prevent issues and ensure the valve continues to operate efficiently.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the automotive industry, Cummins is known for its commitment to innovation, quality, and customer satisfaction. The company’s extensive product line and technological advancements make it a preferred choice for commercial vehicle manufacturers and operators.

Compatibility Overview

The Cummins Air Fuel Throttle Valve part number 3607696 is designed to fit seamlessly with several Cummins engine models, ensuring optimal performance and efficiency. This part is compatible with the following engines:

KTA19GC Series

- KTA19GC

- KTA19GC CM558

The KTA19GC series engines are known for their robust design and reliability, often used in a variety of industrial and marine applications. The Air Fuel Throttle Valve part 3607696 is engineered to integrate smoothly with these engines, providing precise control over the air-fuel mixture, which is essential for maintaining engine performance and reducing emissions.

QSK19G Series

- QSK19G

The QSK19G engine is another high-performance model in Cummins’ lineup, designed for demanding applications such as power generation and heavy-duty transportation. The Air Fuel Throttle Valve part 3607696 is specifically designed to fit this engine, ensuring that it can handle the rigorous demands of these applications. This compatibility is crucial for maintaining the engine’s efficiency and longevity.

Integration with Engine Systems

The Air Fuel Throttle Valve (part 3607696) is integral to the efficient operation of engine systems by regulating the air-fuel mixture entering the combustion chamber. This component works in conjunction with several other parts to ensure optimal engine performance.

Integration with the Throttle Body

The Air Fuel Throttle Valve is mounted within the throttle body, where it modulates the airflow based on the driver’s input via the accelerator pedal. The throttle position sensor (TPS) communicates the throttle’s position to the engine control unit (ECU), which then adjusts the valve’s operation to maintain the desired air-fuel ratio.

Interaction with the Mass Airflow Sensor (MAF)

The mass airflow sensor measures the volume and density of air entering the engine. The ECU uses this data to calculate the required fuel injection amount. The Air Fuel Throttle Valve responds to these calculations by adjusting the throttle opening, ensuring that the correct amount of air is allowed into the engine.

Coordination with the Fuel Injectors

Fuel injectors deliver fuel into the intake manifold or directly into the combustion chamber. The Air Fuel Throttle Valve’s precise control over airflow ensures that the fuel injectors operate under optimal conditions, leading to efficient combustion and reduced emissions.

Role in Idle Control

During idle, the Air Fuel Throttle Valve works with the idle air control (IAC) valve to maintain a stable engine speed. By fine-tuning the airflow, it helps the engine run smoothly without stalling, even when the throttle is closed.

Enhancement of Throttle Response

The valve’s rapid response to changes in throttle position enhances the drivability of the vehicle. Whether accelerating or decelerating, the Air Fuel Throttle Valve ensures that the engine’s power delivery is smooth and responsive.

Contribution to Emissions Control

By maintaining an optimal air-fuel ratio, the Air Fuel Throttle Valve plays a significant role in reducing harmful emissions. It ensures that the catalytic converter operates efficiently, converting pollutants into less harmful substances.

Support for Engine Load Management

Under varying engine loads, the Air Fuel Throttle Valve adapts to maintain efficient combustion. Whether climbing a hill or cruising on a flat road, it ensures that the engine operates within its optimal performance range.

Conclusion

The Air Fuel Throttle Valve 3607696 is a key component in the orchestration of various engine systems, ensuring that the engine operates efficiently, responsively, and with minimal emissions. Its precise control over the air-fuel mixture contributes to improved engine performance, enhanced fuel efficiency, and better emissions control, making it an essential part of the engine system in commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.