This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

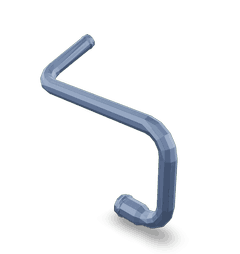

The Compressor Air Inlet Tube, identified by Part #3607458, is a component manufactured by Cummins, a leading name in the automotive and heavy-duty truck industries. This tube is integral to the efficient operation of heavy-duty trucks, facilitating the smooth flow of air into the compressor. Cummins, known for its commitment to innovation and quality, ensures that this component meets the rigorous demands of heavy-duty applications 1.

Basic Concepts and Functionality

The Compressor Air Inlet Tube operates on the fundamental principle of directing air flow efficiently into the compressor. Within the truck’s air system, it serves as a conduit that channels air from the outside environment into the compressor, where it is pressurized and utilized for various engine functions. Its design and placement are crucial for maintaining optimal air flow, which is vital for the compressor’s performance and, by extension, the truck’s overall efficiency 2.

Purpose of the Compressor Air Inlet Tube

The primary role of the Compressor Air Inlet Tube in a truck’s operation is to ensure a consistent and unobstructed supply of air to the compressor. This contributes to the vehicle’s performance and reliability by supporting the compressor’s function in pressurizing air for engine operations. Efficient air flow through this tube is key to maintaining the compressor’s efficiency and, consequently, the truck’s operational effectiveness 3.

Key Features

The Compressor Air Inlet Tube is characterized by several key features that enhance its functionality. It is constructed from durable materials designed to withstand the harsh conditions typical of heavy-duty truck environments. Its design includes features that facilitate easy installation and integration into the truck’s air system, ensuring a secure and effective fit. Additionally, the tube may incorporate elements that reduce noise levels and improve air filtration, contributing to the overall efficiency of the air system 4.

Benefits

The advantages of the Compressor Air Inlet Tube include improved air filtration, which helps protect the compressor from contaminants. Reduced noise levels contribute to a quieter operating environment. Enhanced durability ensures long-term reliability, and potential increases in engine efficiency and longevity can be attributed to the optimized air flow facilitated by this component 5.

Installation and Integration

Proper installation of the Compressor Air Inlet Tube involves several steps to ensure it is securely and effectively integrated into the truck’s air system. Preparations may include cleaning the installation area and inspecting the tube for any damage. Tools required for installation will vary but may include wrenches and sealants. Careful attention to the manufacturer’s guidelines is recommended to achieve a secure fit and optimal performance 6.

Troubleshooting and Maintenance

Common issues with the Compressor Air Inlet Tube may include blockages, leaks, or damage from environmental factors. Diagnostic techniques for assessing its condition involve visual inspections and testing for air flow efficiency. Recommended maintenance practices include regular cleaning to remove contaminants, checking for signs of wear or damage, and ensuring all connections are secure. These practices help prolong the service life of the tube and maintain its performance 7.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and customer satisfaction within the automotive and heavy-duty truck industries. The company’s product range includes engines, filtration systems, and other components designed to meet the demanding requirements of various applications, underscoring Cummins’ commitment to excellence and reliability 8.

Cummins Compressor Air Inlet Tube 3607458 Compatibility

The Cummins Compressor Air Inlet Tube part number 3607458 is designed to fit seamlessly with several engine models, ensuring optimal performance and reliability. This part is integral to the engine’s air intake system, facilitating the smooth flow of air into the compressor.

C GAS PLUS CM556 and L GAS PLUS CM556 Engines

The Compressor Air Inlet Tube 3607458 is compatible with the C GAS PLUS CM556 and L GAS PLUS CM556 engines. These engines are part of Cummins’ range of gas-powered engines, known for their efficiency and durability. The part’s design ensures it fits perfectly with these models, maintaining the integrity of the air intake system and contributing to the engine’s overall performance.

C8.3 G Engine

Similarly, the Compressor Air Inlet Tube 3607458 is also compatible with the C8.3 G engine. This engine is another example of Cummins’ commitment to providing high-quality, reliable power solutions. The part’s precise fitment with the C8.3 G engine ensures that the air intake system functions as intended, supporting the engine’s operational efficiency and longevity.

Ensuring Compatibility and Performance

When replacing or maintaining the Compressor Air Inlet Tube 3607458, it is crucial to ensure that the part is correctly fitted to the specified engine models. This compatibility is essential for maintaining the engine’s performance and preventing potential air intake issues that could affect overall engine efficiency.

Understanding the Role of Part 3607458 Compressor Air Inlet Tube in Engine Systems

The Compressor Air Inlet Tube, identified by part number 3607458, is an essential component in the arrangement of an engine’s air intake system. This tube is responsible for directing ambient air into the compressor section of the engine, where it is pressurized before entering the combustion chamber.

Integration with Compressor Air Inlet

The Compressor Air Inlet is the gateway through which air enters the engine’s compressor. The 3607458 Compressor Air Inlet Tube plays a significant role here by ensuring a smooth and uninterrupted flow of air. This is achieved by its precise design, which minimizes turbulence and pressure loss as air moves from the external environment into the compressor.

Functionality in the System

Once air is drawn in through the Compressor Air Inlet, it travels through the 3607458 Compressor Air Inlet Tube. The tube’s design is optimized to handle the high velocities and pressures associated with the compressor’s operation. It ensures that the air entering the compressor is clean and free from contaminants, which is vital for the efficient operation and longevity of the compressor blades.

Impact on Engine Performance

The efficiency of the 3607458 Compressor Air Inlet Tube directly influences the overall performance of the engine. By providing a consistent and clean air supply to the compressor, it helps in maintaining optimal compression ratios. This, in turn, enhances the engine’s power output and fuel efficiency. Additionally, the tube’s role in reducing air turbulence contributes to a more stable compressor operation, reducing the risk of compressor stall or surge.

Maintenance and Reliability

Regular inspection and maintenance of the 3607458 Compressor Air Inlet Tube are important for ensuring the reliability of the engine system. Any damage or blockage in the tube can lead to reduced airflow, affecting the compressor’s performance and potentially leading to engine inefficiencies or failures. Therefore, it is essential to monitor the condition of this component as part of routine engine maintenance.

Conclusion

In summary, the 3607458 Compressor Air Inlet Tube is a key element in the air intake arrangement of engine systems. Its role in facilitating a smooth and efficient airflow into the compressor is fundamental to the engine’s performance and reliability. Proper installation, maintenance, and understanding of its functionality are crucial for maximizing the efficiency and longevity of heavy-duty truck engines.

-

Denton, T., & Pells, H. (2022). Automotive Technician Training Theory. Routledge.

↩ -

Arora, S., Abkenar, A. T., & Jayasi, S. G. (2021). Heavyduty Electric Vehicles: From Concept to Reality. Elsevier.

↩ -

Smil, V. (2010). The History and Impact of Diesel Engines and Gas Turbines. The MIT Press.

↩ -

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩ -

Denton, T., & Pells, H. (2022). Automotive Technician Training Theory. Routledge.

↩ -

Arora, S., Abkenar, A. T., & Jayasi, S. G. (2021). Heavyduty Electric Vehicles: From Concept to Reality. Elsevier.

↩ -

Smil, V. (2010). The History and Impact of Diesel Engines and Gas Turbines. The MIT Press.

↩ -

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.