This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 2862261 Air Tube is a component designed for use in commercial trucks. It serves a specific function within the vehicle’s air system, contributing to the overall operation and performance of the truck. Understanding its purpose and role is fundamental for maintaining and optimizing the efficiency of commercial vehicles.

Basic Concepts of Air Tubes

Air tubes are conduits used in pneumatic systems to transport compressed air from one point to another. They are integral to various functions within a truck, including braking systems, suspension, and other air-operated components. The efficiency of these systems relies on the integrity and design of the air tubes, which must withstand pressure, environmental conditions, and the rigors of daily use 1.

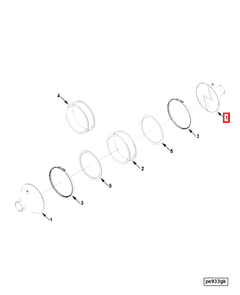

Purpose and Function of the Cummins 2862261 Air Tube

This Cummins part is designed to facilitate the flow of compressed air within a truck’s air system. It connects different components, ensuring that air reaches where it is needed for operation. This air tube contributes to the vehicle’s efficiency by maintaining consistent air pressure and flow, which is vital for the performance of air-dependent systems 2.

Key Features

The Cummins 2862261 Air Tube is constructed with materials and design elements that enhance its performance and durability. Its material composition is chosen to resist corrosion and withstand the pressures of the air system. Design elements such as reinforced joints and a smooth interior surface are incorporated to optimize air flow and reduce the risk of leaks 3.

Benefits of Using the Cummins 2862261 Air Tube

Utilizing this part offers several advantages. It provides improved air flow due to its design, which can lead to enhanced performance of air-operated systems. Its durable construction contributes to longevity, reducing the frequency of replacements. Additionally, the efficient design may lead to potential cost savings for fleet operators by minimizing maintenance needs and downtime.

Installation and Integration

Proper installation of this Cummins part is key to ensuring optimal performance. It should be integrated into the truck’s air system with attention to secure connections and correct alignment. Prerequisites for installation may include ensuring the system is free of debris and that all connections are compatible with the tube’s design.

Troubleshooting Common Issues

Common problems with air tubes can include leaks, blockages, or damage from wear and tear. Identifying the source of these issues is the first step in troubleshooting. Recommended steps may involve inspecting connections for tightness, checking for physical damage, and ensuring that the tube is correctly installed within the system.

Maintenance Tips

Routine maintenance of the Cummins 2862261 Air Tube is important for ensuring its longevity and consistent performance. This includes regular inspections for signs of wear or damage, cleaning connections to prevent debris buildup, and following manufacturer guidelines for care and replacement schedules.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a broad product range, Cummins is committed to advancing technology in the automotive and engine manufacturing industry. Their components, including the Cummins 2862261 Air Tube, are designed with a focus on reliability, performance, and durability.

Compatibility with Cummins Engines

The Air Tube part number 2862261, manufactured by Cummins, is designed to fit seamlessly within a range of Cummins engines. Specifically, this air tube is compatible with the following engine models:

- G5.9 CM558

- G8.3 CM558

- G855 CM558

These engines, while differing in their specific configurations and performance metrics, share a commonality in their design that allows the air tube to integrate effectively. The air tube is engineered to ensure optimal airflow management within the engine’s system, contributing to efficient engine operation and performance.

Role in Aftertreatment Systems

The 2862261 Air Tube is integral to the efficient operation of aftertreatment systems in modern engines. This component facilitates the transport of exhaust gases from the engine to various aftertreatment devices, ensuring that emissions are managed effectively before they are released into the atmosphere.

In the context of an aftertreatment device, the Air Tube plays a significant role in directing exhaust gases to components such as Diesel Particulate Filters (DPFs), Selective Catalytic Reduction (SCR) systems, and Diesel Oxidation Catalysts (DOCs). By providing a secure and leak-free pathway, the Air Tube ensures that these devices receive a consistent flow of exhaust gases, which is necessary for their optimal performance.

The Air Tube also contributes to the overall durability and reliability of the aftertreatment system. It is designed to withstand high temperatures and pressures, which are common in exhaust systems. This resilience helps maintain the integrity of the aftertreatment devices, allowing them to effectively reduce harmful emissions such as nitrogen oxides (NOx) and particulate matter (PM).

Furthermore, the Air Tube is engineered to accommodate the thermal expansion and contraction that occur within the exhaust system. This flexibility prevents stress on connected components, enhancing the longevity of the aftertreatment devices and the entire exhaust system.

Conclusion

In summary, the Cummins 2862261 Air Tube is a vital component in both the air system and aftertreatment systems of commercial trucks. Its robust construction, efficient design, and compatibility with various Cummins engines make it an essential part for maintaining vehicle performance and reducing emissions. Regular maintenance and proper installation are key to maximizing the benefits of this component.

-

Sully, F. K. (1998). Motor Vehicle Mechanics Textbook, Fifth Edition. Heinemann Professional Publishing.

↩ -

Klyde, M., & VanGelder, K. (2010). Advanced Automotive Electricity and Electronics. Jones Bartlett Learning.

↩ -

Pulkrabek, W. W. (2014). Engineering Fundamentals of the Internal Combustion Engine. Pearson Education.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.