2866337

Aftertreatment Device Gasket

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Aftertreatment Device Gasket 2866337, manufactured by Cummins, is a specialized component designed for use in commercial truck operations. This gasket is integral to the aftertreatment system, which is responsible for reducing harmful emissions from diesel engines. Cummins, a well-respected name in the automotive industry, produces this gasket to meet the stringent emissions standards required for modern commercial vehicles 1.

Basic Concepts of Aftertreatment Device Gaskets

Aftertreatment device gaskets are sealing components used within the emissions control system of a truck. Their primary function is to ensure a secure and leak-free connection between various parts of the aftertreatment system, such as the diesel particulate filter (DPF), selective catalytic reduction (SCR) system, and exhaust gas recirculation (EGR) system. By maintaining these seals, aftertreatment device gaskets contribute to the efficient operation of the emissions control system, helping to reduce the release of harmful pollutants into the atmosphere 2.

Role of the 2866337 Aftertreatment Device Gasket

Positioned between critical components, the 2866337 ensures that exhaust gases flow smoothly and without leaks through the system. Its interaction with other components, such as the DPF and SCR catalyst, is vital for maintaining the integrity of the emissions control process. By providing a reliable seal, this Cummins part helps to optimize the performance of the aftertreatment system, ensuring that emissions are effectively managed 3.

Key Features

The 2866337 Aftertreatment Device Gasket is designed with several key features that enhance its performance and durability. Constructed from high-quality materials, this gasket is resistant to the high temperatures and pressures encountered in the exhaust system. Its design includes precise dimensions and a robust structure to ensure a secure fit and long-lasting seal. Additionally, the gasket may incorporate unique attributes such as heat-resistant coatings or reinforced edges to further improve its reliability under demanding conditions.

Benefits

The use of the 2866337 Aftertreatment Device Gasket offers several benefits for commercial truck operations. By ensuring a tight seal within the aftertreatment system, this gasket contributes to improved emissions control, helping trucks to meet regulatory standards. Enhanced system reliability is another advantage, as a well-sealed aftertreatment system is less prone to leaks and malfunctions. Furthermore, optimal performance of the aftertreatment system can lead to potential improvements in fuel efficiency and overall engine performance, providing economic benefits for fleet operators.

Troubleshooting and Maintenance

Common issues that may arise with the 2866337 Aftertreatment Device Gasket include leaks, wear, and damage due to extreme conditions. Recommended troubleshooting steps involve inspecting the gasket for signs of deterioration, such as cracks or deformation, and ensuring that it is properly installed. Regular maintenance practices, such as checking for proper torque on fasteners and monitoring the condition of the gasket during routine service intervals, can help to ensure optimal performance and longevity of the aftertreatment system.

About Cummins

Cummins is a renowned manufacturer with a long-standing reputation in the automotive industry. Founded in 1919, the company has a history of innovation and quality in the production of diesel engines and related components. Cummins is committed to advancing technology and sustainability in the automotive sector, consistently delivering high-performance products that meet the needs of commercial vehicle operators. Their dedication to excellence is evident in the design and manufacturing of components like the 2866337 Aftertreatment Device Gasket.

Cummins Aftertreatment Device Gasket 2866337 Compatibility

The Cummins Aftertreatment Device Gasket 2866337 is designed to fit seamlessly with a range of Cummins engines, ensuring optimal performance and durability. This gasket is essential for maintaining the integrity of the aftertreatment system, which is crucial for reducing emissions and meeting environmental standards.

QSX11.9 CM2250 ECF and QSX15 CM2250 ECF

The QSX11.9 CM2250 ECF and QSX15 CM2250 ECF engines are part of Cummins’ lineup that incorporates advanced aftertreatment technology. The 2866337 gasket is engineered to fit these engines, providing a reliable seal that prevents leaks and ensures the system operates efficiently. This compatibility is critical for maintaining the performance and longevity of these engines.

QSX15 CM2250

The QSX15 CM2250 engine also benefits from the 2866337 gasket. This gasket is specifically designed to fit the aftertreatment components of the QSX15 CM2250, ensuring a secure and leak-free connection. The use of this gasket helps in maintaining the efficiency of the aftertreatment system, which is vital for the engine’s overall performance and compliance with emission regulations.

Compatibility Summary

- QSX11.9 CM2250 ECF

- QSX15 CM2250 ECF

- QSX15 CM2250

The 2866337 gasket is a critical component for the aftertreatment systems of these engines, ensuring that the system operates as intended and meets the necessary environmental standards.

Role of Part 2866337 Aftertreatment Device Gasket in Engine Systems

The Aftertreatment Device Gasket (part 2866337) is an essential component in the assembly and operation of various engine systems. Its primary function is to ensure a secure and leak-free seal between the aftertreatment device and the surrounding components.

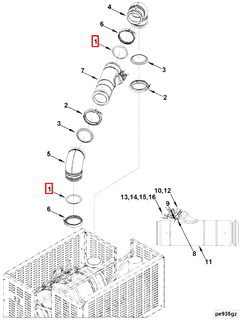

Integration with Aftertreatment Device

When installing the aftertreatment device, the gasket is positioned between the device and the mounting surface. This placement is vital for maintaining the integrity of the seal, which prevents exhaust gases from escaping. The gasket accommodates any minor misalignments or irregularities in the surfaces, ensuring a consistent seal across the entire interface.

Contribution to Aftertreatment System

Within the aftertreatment system, the gasket plays a supportive role by facilitating the efficient flow of exhaust gases through the system. By preventing leaks, it ensures that the aftertreatment processes, such as catalytic conversion and particulate filtration, operate under optimal conditions. This enhances the overall effectiveness of the aftertreatment system in reducing emissions.

Exhaust Outlet Connection

At the exhaust outlet connection, the gasket is critical for maintaining a tight seal. This prevents exhaust gases from bypassing the aftertreatment device, which could lead to increased emissions and decreased system efficiency. The gasket’s durability and flexibility are important in withstanding the high temperatures and pressures present in the exhaust system.

Exhaust Plumbing

In the context of exhaust plumbing, the gasket ensures that the connections between various exhaust components remain sealed. This is particularly important in maintaining the backpressure within the exhaust system, which is necessary for the proper functioning of turbochargers and other exhaust-driven components. A well-sealed system also minimizes the risk of exhaust leaks, which can pose safety hazards.

Hardware Kit

The gasket is often included in hardware kits designed for the installation or replacement of aftertreatment devices. These kits typically contain all necessary components to ensure a proper installation, including bolts, washers, and the gasket itself. The gasket’s role in these kits is to provide the necessary sealing capability, ensuring that the aftertreatment device is installed correctly and functions as intended.

Conclusion

The 2866337 Aftertreatment Device Gasket is a critical component in the emissions control system of commercial trucks. Its role in ensuring a secure and leak-free seal between aftertreatment devices and surrounding components is vital for the efficient operation of the system. By preventing leaks and maintaining the integrity of the seal, this Cummins part contributes to improved emissions control, enhanced system reliability, and potential improvements in fuel efficiency and engine performance. Regular maintenance and proper installation are essential to ensure the longevity and effectiveness of the aftertreatment system.

-

The Automotive Transmission Book Powertrain, Robert Fischer, Ferit Kucukay, Gunter Jurgens, Rolf Najork, and Burkhard Pollak, Springer, 2015.

↩ -

Light and Heavy Vehicle Technology, Fourth Edition, MJ Nunney, Butterworth-Heinemann, 2007.

↩ -

The Automotive Body, Frederick F. Ling, Springer Science, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.