This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

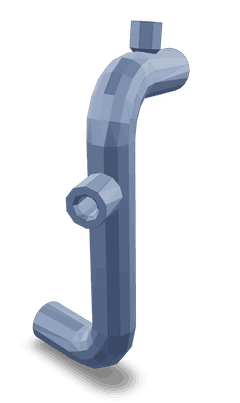

The Cummins Aftercooler Tube 3899396 is a component designed for use in heavy-duty trucks. It plays a role in the engine system by cooling compressed air before it enters the engine, ensuring optimal operating conditions 1.

Basic Concepts of Aftercooler Tubes

An aftercooler tube is a component within the engine cooling system that cools compressed air. This process is vital for maintaining optimal engine performance, as it ensures that the air entering the engine is at the correct temperature 2. By reducing the temperature of the compressed air, the aftercooler tube helps to increase the density of the air, which can lead to more efficient combustion and improved engine performance.

Purpose of the Cummins Aftercooler Tube 3899396

The Cummins Aftercooler Tube 3899396 is integral to the truck’s engine system by cooling the compressed air before it enters the engine. This cooling process helps to reduce thermal stress on engine components, which can lead to a longer lifespan for these parts. Additionally, it contributes to more efficient combustion, which can improve overall engine performance 3.

Key Features

The Cummins Aftercooler Tube 3899396 is constructed from high-quality materials, ensuring durability and reliability. Its design includes features that enhance its performance, such as a robust construction that can withstand the high pressures and temperatures within the engine system. Additionally, it is designed to be compatible with a variety of truck models and engine types, making it a versatile component for heavy-duty applications.

Benefits of Using the Cummins Aftercooler Tube 3899396

Using the Cummins Aftercooler Tube 3899396 can provide several advantages. It contributes to improved engine efficiency by ensuring that the air entering the engine is at the optimal temperature. This can lead to more efficient combustion and reduced thermal stress on engine components. Additionally, it can enhance overall engine performance, leading to better fuel efficiency and power output 4.

Installation Considerations

When installing the Cummins Aftercooler Tube 3899396, it is important to follow guidelines and best practices to ensure proper fit and function. This includes ensuring compatibility with the specific truck model and engine type. Additionally, any specific installation requirements or recommendations provided by the manufacturer should be followed to ensure optimal performance and longevity of the component.

Maintenance and Troubleshooting

Regular maintenance of the Cummins Aftercooler Tube 3899396 is important to ensure its continued performance and longevity. This includes regular inspection procedures to check for any signs of wear or damage. Cleaning methods should be employed to remove any buildup that could impede the cooling process. Additionally, troubleshooting common issues that may arise during operation can help to identify and address any problems before they lead to more significant issues.

Performance Enhancements

The Cummins Aftercooler Tube 3899396 contributes to overall engine performance in several ways. By ensuring that the air entering the engine is at the optimal temperature, it can lead to more efficient combustion and improved fuel efficiency. Additionally, it can contribute to increased power output and longevity of engine components by reducing thermal stress.

Environmental Impact

The use of the Cummins Aftercooler Tube 3899396 can have positive environmental impacts. By contributing to more efficient combustion and improved fuel efficiency, it can lead to reduced emissions. Additionally, it can contribute to more sustainable trucking operations by improving the overall performance and longevity of the engine.

Compatibility of Aftercooler Tube Part 3899396 with Cummins Engines

The Aftercooler Tube part number 3899396, manufactured by Cummins, is designed to fit seamlessly with several models of Cummins engines. Specifically, this part is compatible with the M11 CELECT PLUS and M11 MECHANICAL engines.

In the context of the M11 CELECT PLUS engine, the Aftercooler Tube plays a role in the engine’s cooling system. It ensures that the air entering the engine is at an optimal temperature, enhancing overall performance and efficiency. The design of the tube is engineered to withstand the high pressures and temperatures associated with these engines, ensuring durability and reliability.

Similarly, for the M11 MECHANICAL engine, the Aftercooler Tube part 3899396 is a component. It is integral to the engine’s cooling process, helping to maintain the air temperature at an ideal level. This part is constructed to meet the stringent demands of the M11 MECHANICAL engine, providing consistent performance and longevity.

Both engines benefit from the precision engineering of the Aftercooler Tube, which is important for maintaining the efficiency and reliability of the engine’s cooling system. The compatibility of this part with both the M11 CELECT PLUS and M11 MECHANICAL engines underscores its versatility and importance in ensuring optimal engine operation.

Role of Part 3899396 Aftercooler Tube in Engine Systems

The Part 3899396 Aftercooler Tube is an integral component in the efficient operation of engine systems, particularly in those utilizing aftercooling technology. This tube facilitates the connection between various components, ensuring seamless fluid dynamics and thermal management within the engine.

Integration with Plumbing Systems

In engine systems, the Aftercooler Tube is often integrated with the plumbing network. Its primary function here is to direct the flow of coolant from the aftercooler to other parts of the engine that require cooling. This ensures that the engine maintains optimal operating temperatures, which is important for performance and longevity. The tube’s design allows for minimal resistance to fluid flow, which enhances the efficiency of the cooling process.

Interaction with Aftercooler Water Circuits

The Aftercooler Tube plays a role in the aftercooler water circuits. Aftercoolers are devices used to cool compressed air before it enters the engine’s combustion chamber. The Aftercooler Tube transports water from the aftercooler to the engine’s water pump or directly to the engine block, depending on the system’s design. This circulation helps in dissipating heat from the compressed air, which in turn reduces the temperature of the air entering the combustion chamber. Lower air temperatures result in more efficient combustion and increased engine performance.

Enhancing Engine Efficiency

By effectively managing the flow of coolant and aftercooler water, the Aftercooler Tube contributes to the overall efficiency of the engine. It ensures that the engine components are kept within their optimal temperature ranges, which prevents overheating and potential damage. Additionally, the tube’s role in the aftercooler system helps in maintaining consistent air temperatures, which is vital for stable engine operation under varying load conditions.

Supporting System Reliability

The reliable operation of the Aftercooler Tube is fundamental to the stability of the engine system. Its durable construction and precise fitting ensure that there are no leaks or disruptions in the coolant and aftercooler water flow. This reliability is important for maintaining the engine’s performance over time and under different operating conditions.

Conclusion

In summary, the Cummins Aftercooler Tube 3899396 is a key component in the thermal management and fluid dynamics of engine systems. Its integration with plumbing and aftercooler water circuits ensures efficient cooling and stable engine operation, contributing to the overall reliability and performance of the engine.

-

Stiesch, G. (2003). Modeling Engine Spray and Combustion Processes. Springer Verlag.

↩ -

Gifford, C. (2014). Cars Encyclopedia. DK Publishing.

↩ -

Khajepour, A. (2023). Synthesis Lectures on Advances in Automotive Technology. Springer.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2019). Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.