This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

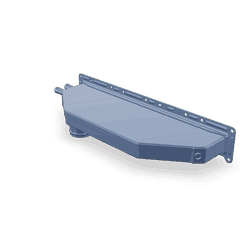

The Cummins 5262314 Aftercooler is a component designed to enhance the performance and efficiency of commercial trucks. Its role in the engine system is significant, contributing to the overall functionality and reliability of the vehicle. This aftercooler is part of Cummins Inc.’s range of products aimed at improving the operational aspects of heavy-duty trucks.

Basic Concepts of Aftercoolers

An aftercooler is a device used in internal combustion engines to cool and condense the air after it has been compressed by a turbocharger. This process increases the density of the air, allowing more oxygen to enter the engine, which in turn enhances combustion efficiency. The principles of air cooling technology involve transferring heat from the compressed air to a cooling medium, typically ambient air, to achieve the desired temperature and moisture reduction 1.

Purpose of the Cummins 5262314 Aftercooler

The Cummins 5262314 Aftercooler functions within a truck’s engine system by cooling the compressed air from the turbocharger before it enters the engine’s intake system. This cooling process increases the air density, leading to more efficient combustion and improved engine performance. The aftercooler is integral to maintaining optimal engine operation under various driving conditions.

Key Features

The Cummins 5262314 Aftercooler is characterized by its robust design, which includes high-quality materials to ensure durability and efficiency. Key features include a compact yet effective cooling structure, corrosion-resistant materials, and a design that facilitates easy installation and maintenance. These elements contribute to the aftercooler’s reliability and performance in demanding commercial applications.

Benefits of Using the Cummins 5262314 Aftercooler

Utilizing the Cummins 5262314 Aftercooler offers several advantages. It contributes to improved engine performance by ensuring that the air entering the engine is at an optimal temperature and density. This results in increased fuel efficiency, as the engine operates more effectively. Additionally, the aftercooler enhances the durability of the engine components by reducing the thermal stress caused by hot air intake 2.

Installation Process

Installing the Cummins 5262314 Aftercooler requires careful attention to ensure proper integration into the engine system. The process involves disconnecting the existing aftercooler, if present, and connecting the new unit to the turbocharger and intake system. Tools required may include wrenches, hose clamps, and possibly a torque wrench to ensure connections are secure. Following the manufacturer’s guidelines is crucial for a successful installation.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 5262314 Aftercooler, routine maintenance is recommended. This includes regular inspection for signs of corrosion, leaks, or blockages within the cooling system. Cleaning the aftercooler’s exterior and ensuring that all connections are tight can prevent issues related to air flow and cooling efficiency. Additionally, monitoring the engine’s performance can indicate whether the aftercooler is functioning correctly.

Troubleshooting Common Issues

Common problems associated with aftercoolers may include reduced cooling efficiency, leaks, or blockages. Troubleshooting steps involve checking for visible signs of damage or wear, ensuring all connections are secure, and verifying that the cooling system is free from obstructions. Solutions may range from simple repairs, such as tightening connections, to more complex interventions like replacing damaged components.

Environmental Impact

The use of the Cummins 5262314 Aftercooler contributes to environmental benefits by improving engine efficiency and reducing fuel consumption. This leads to lower emissions of harmful pollutants, aligning with efforts to minimize the environmental footprint of commercial transportation. The aftercooler’s role in enhancing engine performance indirectly supports more sustainable operations in the trucking industry.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and a strong reputation in the commercial truck industry, Cummins products are known for their reliability, performance, and efficiency. The company’s commitment to quality and customer satisfaction has established it as a trusted name in the automotive and heavy-duty truck sectors.

Cummins Aftercooler Part 5262314 Compatibility

The Cummins Aftercooler part number 5262314 is designed to fit a range of Cummins engines, enhancing their performance and efficiency. This aftercooler is compatible with several models, including the 6C8.3, G8.3, GTA8.3 CM558, and QSL9 G CM558 engines.

For the 6C8.3 and G8.3 engines, the aftercooler ensures optimal air intake by cooling the compressed air from the turbocharger, which helps in achieving better fuel efficiency and power output.

In the case of the GTA8.3 CM558 and QSL9 G CM558 engines, the aftercooler plays a significant role in maintaining the integrity of the air entering the engine. This is particularly important in high-performance applications where the engine operates under significant stress.

By integrating the aftercooler part number 5262314 into these engines, users can expect improved engine longevity and performance, making it a valuable component for both maintenance and upgrading purposes.

Role of Part 5262314 Aftercooler in Engine Systems

In the orchestration of engine systems, the aftercooler (part 5262314) assumes a significant role by ensuring the air entering the engine is at an optimal temperature. This is particularly important in turbocharged engines where the air is compressed and consequently heated. The aftercooler, positioned downstream of the turbocharger, is designed to cool this compressed air before it enters the engine’s combustion chambers.

The aftercooler housing is the enclosure that houses the aftercooler. It is engineered to facilitate the efficient transfer of heat from the compressed air to a coolant, typically air or liquid, circulating within the housing. This housing is integral to maintaining the structural integrity and operational efficiency of the aftercooler.

In the arrangement of engine components, the aftercooler is strategically placed to maximize its effectiveness. It is commonly situated between the turbocharger and the engine intake. This placement ensures that the air is cooled immediately after being compressed, minimizing the risk of heat-related performance issues and enhancing the overall efficiency of the engine.

The turbocharger plays a pivotal role in this system by compressing the intake air, which increases its density and allows more air to enter the engine. However, this compression process also raises the air temperature, which can lead to decreased engine efficiency and potential damage. The aftercooler mitigates these effects by reducing the temperature of the compressed air, thereby optimizing the air-fuel mixture and improving combustion efficiency.

In summary, the integration of part 5262314 aftercooler within the engine system, particularly in turbocharged applications, is essential for maintaining optimal air temperature. This, in turn, enhances engine performance, efficiency, and longevity.

Conclusion

The Cummins 5262314 Aftercooler is a vital component in the engine systems of commercial trucks, designed to enhance performance and efficiency. By cooling the compressed air from the turbocharger, this part ensures optimal air intake temperature, leading to improved combustion efficiency, increased fuel efficiency, and enhanced engine durability. Its robust design, ease of installation, and maintenance make it a reliable choice for heavy-duty applications. Additionally, the environmental benefits of reduced emissions and fuel consumption contribute to more sustainable operations in the trucking industry.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.