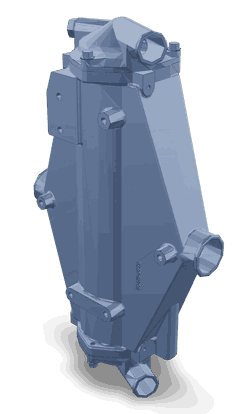

The Cummins 5261994 Aftercooler is a component designed to enhance the performance and efficiency of heavy-duty truck engines. It operates by cooling the compressed air from the turbocharger before it enters the engine’s combustion chamber. This cooling process increases the air density, allowing for more efficient combustion and improved engine performance 1.

Basic Concepts of Aftercoolers

An aftercooler, also known as an intercooler, is a device used in turbocharged engines to reduce the temperature of the compressed air. This is achieved through heat exchange, where the hot compressed air passes through a series of tubes or fins and is cooled by ambient air or a liquid coolant. The cooled air is denser, which allows for more oxygen to enter the combustion chamber, enhancing engine efficiency and power output 2.

Purpose of the Cummins 5261994 Aftercooler

The Cummins 5261994 Aftercooler plays a specific role in the engine system by reducing the temperature of the compressed air from the turbocharger. This cooling process increases the air density, which in turn allows for more efficient combustion. The result is enhanced engine performance, improved fuel efficiency, and reduced emissions.

Key Features

The Cummins 5261994 Aftercooler is characterized by its robust design and high-quality materials. It features a compact yet efficient heat exchange system, constructed from durable materials to withstand the harsh conditions of heavy-duty truck operations. Unique attributes include its ability to maintain optimal cooling efficiency under varying load conditions and its integration with other engine components for seamless operation.

Benefits of Using the Cummins 5261994 Aftercooler

Utilizing the Cummins 5261994 Aftercooler offers several advantages. It contributes to improved engine longevity by ensuring optimal combustion conditions, which reduce wear and tear on engine components. Enhanced fuel efficiency is another benefit, as the denser air allows for more complete combustion, leading to better fuel economy. Additionally, the aftercooler helps in reducing emissions by promoting cleaner and more efficient combustion processes.

Installation Process

Installing the Cummins 5261994 Aftercooler involves several steps to ensure proper integration with the engine system. Preparatory steps include disconnecting the battery to prevent electrical issues and ensuring the engine is cool. The aftercooler should be aligned with the turbocharger and secured in place using the provided mounting brackets. Connections to the air intake system must be sealed properly to prevent air leaks. Tools required include wrenches, sealant, and possibly a torque wrench to ensure proper tightening of bolts.

Maintenance Tips

Regular maintenance of the Cummins 5261994 Aftercooler is vital for its longevity and optimal performance. This includes periodic inspection for any signs of damage or wear, ensuring all connections are secure and leak-free, and cleaning the aftercooler fins to remove any debris that may obstruct airflow. It is also important to monitor the overall condition of the cooling system to ensure it operates efficiently.

Troubleshooting Common Issues

Common issues with aftercoolers may include reduced cooling efficiency, air leaks, or physical damage to the unit. Potential causes for these issues can range from improper installation to wear and tear over time. Suggested solutions include re-sealing connections, replacing damaged components, and ensuring the aftercooler is properly aligned and secured within the engine system.

Performance Enhancements

The Cummins 5261994 Aftercooler contributes to overall truck performance by ensuring that the engine receives cool, dense air for combustion. This results in increased power output and improved reliability, as the engine operates under optimal conditions. The aftercooler also plays a role in maintaining consistent performance across varying load conditions, enhancing the truck’s operational efficiency.

Environmental Impact

The use of the Cummins 5261994 Aftercooler has positive environmental implications. By promoting more efficient combustion, it helps in reducing fuel consumption and emissions. The aftercooler’s role in enhancing engine efficiency directly contributes to lower greenhouse gas emissions and a reduced carbon footprint, aligning with environmental sustainability goals.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a strong reputation for quality and innovation, Cummins has been at the forefront of diesel engine and component manufacturing for decades. Their commitment to excellence and continuous improvement ensures that their products, including the Cummins 5261994 Aftercooler, meet the high standards required for heavy-duty applications.

Role of Part 5261994 Aftercooler in Engine Systems

The integration of part 5261994, the Aftercooler, within engine systems is a sophisticated process that enhances overall engine performance and efficiency. This component is strategically positioned post-turbocharger, where it plays a significant role in cooling the compressed air before it enters the engine’s combustion chamber.

In a typical turbocharger arrangement, the Aftercooler is placed immediately after the turbocharger. The turbocharger compresses the intake air, which significantly increases its temperature. The Aftercooler then steps in to reduce this temperature, ensuring that the air entering the engine is at an optimal temperature for efficient combustion. This cooling process not only improves engine efficiency but also helps in reducing the risk of detonation, a condition where the air-fuel mixture ignites prematurely.

The Aftercooler’s effectiveness is further enhanced when it is part of a well-designed package that includes an oil cooler. The oil cooler works in tandem with the Aftercooler to maintain the engine’s operating temperatures within safe limits. This synergy between the Aftercooler and the oil cooler is vital for the longevity and reliability of the engine.

During product installation, careful consideration must be given to the arrangement of these components. The Aftercooler should be installed in a manner that allows for maximum airflow and efficient heat exchange. This often involves positioning it in a location where it can take advantage of the vehicle’s natural airflow, or in some cases, incorporating additional cooling fans to assist in the heat dissipation process.

In summary, the Aftercooler, as part 5261994, is a key component in the turbocharger arrangement of engine systems. Its role in cooling the compressed air not only enhances engine performance but also contributes to the overall reliability and efficiency of the engine. Proper installation and integration with other cooling components like the oil cooler are essential for maximizing its benefits.

Conclusion

The Cummins 5261994 Aftercooler is a vital component in enhancing the performance, efficiency, and environmental impact of heavy-duty truck engines. Its role in cooling compressed air, integration with other engine components, and contribution to reduced emissions make it an essential part of modern diesel engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.