This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

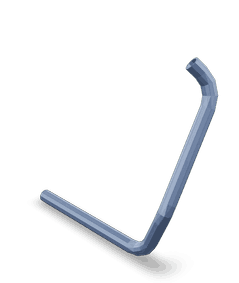

The Aftercooler Tube 4934303, manufactured by Cummins, is a component designed to enhance the efficiency and performance of heavy-duty truck engines. Aftercooler tubes play a significant role in the engine system by facilitating the cooling of compressed air before it enters the engine’s combustion chamber. This process is vital for optimizing engine performance and ensuring longevity. Cummins, a renowned name in engine manufacturing, provides this component as part of its commitment to innovation and quality in the automotive industry 1.

Basic Concepts of Aftercooler Tubes

An aftercooler tube is a part of the engine cooling system that cools the compressed air from the turbocharger before it enters the engine. This cooling process increases the air density, which in turn enhances the engine’s combustion efficiency and power output. By reducing the temperature of the intake air, aftercooler tubes help in maintaining optimal engine operating conditions, thereby contributing to overall engine performance and efficiency 2.

Purpose of the 4934303 Aftercooler Tube

The 4934303 Aftercooler Tube is specifically designed to play a role in the operation of a truck engine by ensuring that the air entering the engine is at an optimal temperature. This component contributes to the engine’s efficiency and performance by facilitating better combustion, which can lead to improved fuel efficiency and power output. Its design and material composition are tailored to withstand the demanding conditions of heavy-duty truck engines, ensuring reliable operation and durability 3.

Key Features

The 4934303 Aftercooler Tube is characterized by its robust material composition and design elements that enhance its durability and efficiency. Made from high-quality materials, this aftercooler tube is designed to resist corrosion and withstand high pressures and temperatures. Its unique design elements include precise engineering to ensure optimal airflow and cooling efficiency, setting it apart from other aftercooler tubes in the market 4.

Benefits

Utilizing the 4934303 Aftercooler Tube offers several benefits, including improved engine cooling, which leads to enhanced engine performance and efficiency. The increased durability of this component can result in longer service intervals and reduced maintenance costs over time. Additionally, the efficient cooling provided by this aftercooler tube can contribute to better fuel economy, offering potential cost savings for fleet operators 5.

Installation Considerations

When installing the 4934303 Aftercooler Tube, it is important to consider its compatibility with specific engine models to ensure optimal performance. Proper installation requires adherence to manufacturer guidelines, including any prerequisites such as ensuring the engine is clean and free of debris. Following these guidelines helps in achieving the best results in terms of engine performance and longevity of the aftercooler tube 6.

Maintenance and Troubleshooting

Routine maintenance practices for the 4934303 Aftercooler Tube include regular inspections for signs of wear or damage, ensuring that all connections are secure, and cleaning the tube to remove any buildup that could impede airflow. Common troubleshooting tips involve checking for leaks, ensuring proper airflow, and addressing any unusual noises or performance issues promptly to maintain the tube’s optimal performance 7.

Performance Impact

The 4934303 Aftercooler Tube impacts engine performance by enhancing fuel efficiency, increasing power output, and contributing to overall engine health. Its role in cooling the intake air ensures that the engine operates under optimal conditions, which can lead to improved combustion efficiency and reduced wear on engine components. This, in turn, can result in better engine performance and longevity 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established itself as a trusted name in the automotive industry. Its expertise in engine manufacturing and dedication to advancing technology ensure that components like the 4934303 Aftercooler Tube meet the high standards required for heavy-duty applications 9.

Cummins Aftercooler Tube 4934303 Compatibility

The Cummins Aftercooler Tube 4934303 is designed to fit seamlessly within various engine configurations, ensuring optimal performance and efficiency. This part is integral to the engine’s cooling system, facilitating the cooling of compressed air before it enters the engine’s combustion chamber.

Engine Compatibility

- 6B5.9 Series

- The 4934303 Aftercooler Tube is specifically engineered to integrate with the 6B5.9 engine series. This engine is known for its robust design and reliability, making it a popular choice in various industrial applications. The aftercooler tube ensures that the air entering the engine is at an optimal temperature, enhancing the engine’s overall performance and longevity.

Installation and Functionality

The installation of the 4934303 Aftercooler Tube is straightforward, designed to fit precisely within the engine’s architecture. This ensures that the cooling process is efficient, reducing the risk of engine overheating and improving fuel efficiency. The tube’s design allows for effective heat exchange, which is crucial for maintaining the engine’s operational efficiency.

Importance of the Aftercooler Tube

The aftercooler tube plays a vital role in the engine’s cooling system. By cooling the compressed air, it helps in reducing the temperature of the air entering the engine, which in turn improves the engine’s power output and efficiency. This component is essential for maintaining the engine’s performance, especially in high-demand applications where temperature management is critical.

Maintenance and Replacement

Regular maintenance of the 4934303 Aftercooler Tube is crucial to ensure that it continues to function effectively. Any signs of wear or damage should be addressed promptly to prevent potential engine issues. Replacement of the aftercooler tube should be carried out by a qualified technician to ensure proper installation and functionality.

Role of Part 4934303 Aftercooler Tube in Engine Systems

The aftercooler tube, specifically part 4934303, is an integral component in the efficient operation of engine systems that utilize aftercooling technology. This tube facilitates the transfer of cooled air from the aftercooler to various parts of the engine, enhancing performance and reliability.

Integration with Plumbing Systems

In engine systems, the aftercooler tube is seamlessly integrated with the plumbing network. This integration ensures that the cooled air is effectively distributed throughout the engine. The tube connects to the aftercooler, which is responsible for reducing the temperature of the compressed air from the turbocharger. The cooled air then travels through the aftercooler tube to the intake manifold, where it mixes with fuel before combustion. This process is vital for maintaining optimal engine temperature and efficiency.

Interaction with Aftercooler Water Systems

The aftercooler tube also plays a significant role in systems that employ water-air aftercooling. In these setups, the tube is part of a closed-loop system where water is circulated to cool the compressed air. The aftercooler tube transports the cooled air from the water-air heat exchanger to the engine’s intake system. This interaction ensures that the air entering the combustion chamber is at the ideal temperature, which is essential for maximizing engine performance and minimizing the risk of detonation.

Enhanced Engine Performance

By efficiently transferring cooled air, the aftercooler tube contributes to several key aspects of engine performance. It helps in reducing the temperature of the intake air, which in turn lowers the likelihood of engine knocking and improves combustion efficiency. Additionally, the consistent supply of cool air supports stable engine operation under varying load conditions, enhancing overall reliability and longevity of the engine components.

Maintenance and Efficiency

Regular inspection and maintenance of the aftercooler tube are essential to ensure its continued effective operation. Any leaks or blockages in the tube can lead to a reduction in cooling efficiency, which may adversely affect engine performance. Therefore, engineers and mechanics should pay close attention to the condition of the aftercooler tube during routine maintenance checks.

Conclusion

In summary, the aftercooler tube (part 4934303) is a vital component in engine systems, particularly those that rely on aftercooling to optimize performance. Its role in facilitating the transfer of cooled air and integrating with both plumbing and aftercooler water systems underscores its importance in maintaining efficient and reliable engine operation.

-

Daniel Williams, Generalized Vehicle Dynamics, SAE International, 2022.

↩ -

Gijs Mom, The Evolution of Automotive Engineering: A Handbook, SAE International, 2023.

↩ -

Klaus Mollenhauer and Helmut Tschoeke, Handbook of Diesel Engines, Springer, 2010.

↩ -

Ben Watson, Mobile Equipment Hydraulics A Systems and Troubleshooting Approach, Cengage Learning, 2011.

↩ -

Cummins Inc., Owners Manual, Bulletin Number 4388787, QSC8.3 CM2880 C102.

↩ -

Cummins Inc., Owners Manual, Bulletin Number 4388787, QSC8.3 CM2880 C102.

↩ -

Cummins Inc., Owners Manual, Bulletin Number 4388787, QSC8.3 CM2880 C102.

↩ -

Cummins Inc., Owners Manual, Bulletin Number 4388787, QSC8.3 CM2880 C102.

↩ -

Cummins Inc., Owners Manual, Bulletin Number 4388787, QSC8.3 CM2880 C102.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.