This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

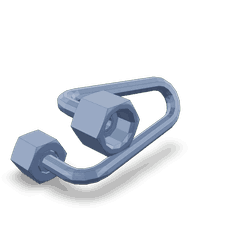

The Aftercooler Tube 4067157 is a component manufactured by Cummins, a well-established name in the commercial truck industry. This part is designed to enhance the efficiency of the engine cooling system. Cummins is known for producing reliable and high-performance parts, and the Aftercooler Tube 4067157 is no exception.

Basic Concepts of Aftercooler Tubes

An aftercooler tube is a component within the engine cooling system that helps to reduce the temperature of compressed air before it enters the engine. This process is vital for maintaining optimal engine performance and efficiency. The aftercooler tube interacts with other components such as the turbocharger and intercooler, ensuring that the air entering the engine is at the correct temperature and pressure 1.

Role of the Aftercooler Tube 4067157 in Truck Operation

The Aftercooler Tube 4067157 plays a specific role in the operation of commercial trucks. It ensures that the air entering the engine is cooled effectively, which contributes to engine efficiency and performance. By maintaining the correct air temperature, the tube helps to prevent overheating and ensures that the engine operates within its designed parameters. This, in turn, can lead to improved fuel efficiency and reduced wear on engine components 2.

Key Features of the Aftercooler Tube 4067157

The Aftercooler Tube 4067157 is constructed with high-quality materials to ensure durability and reliability. Its design includes features that enhance its performance, such as precise engineering to ensure a proper fit within the engine system. The tube is built to withstand the high pressures and temperatures associated with engine operation, making it a robust component in the cooling system 3.

Benefits of Using the Aftercooler Tube 4067157

Using the Aftercooler Tube 4067157 offers several advantages. It contributes to improved engine cooling, which can lead to increased engine efficiency and performance. The tube’s durable construction ensures longevity, reducing the need for frequent replacements. Additionally, by maintaining optimal engine temperatures, the tube can contribute to potential fuel efficiency gains, making it a valuable component for truck operators 4.

Troubleshooting Common Issues with Aftercooler Tubes

Common issues with aftercooler tubes can include signs of wear, potential leaks, and performance issues. Regular inspections can help identify these problems early. Signs of wear may include visible damage to the tube or a decrease in engine performance. Leaks can often be detected by listening for unusual noises or checking for coolant loss. Addressing these issues promptly can help maintain engine efficiency and prevent more significant problems 1.

Maintenance Tips for Aftercooler Tubes

To ensure the longevity and optimal performance of the Aftercooler Tube 4067157, regular maintenance is recommended. This includes routine inspections to check for signs of wear or damage. Cleaning the tube as part of regular engine maintenance can also help prevent buildup that could affect performance. Following the manufacturer’s guidelines for maintenance schedules and procedures will help ensure the tube continues to operate efficiently 2.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company offers a wide range of products designed to meet the needs of various industries, from transportation to construction, ensuring reliable and efficient performance 3.

Cummins Aftercooler Tube Part 4067157 Compatibility

The Cummins Aftercooler Tube part number 4067157 is designed to fit seamlessly within several of Cummins’ renowned engine models. This part is integral to the engine’s cooling system, ensuring optimal performance and longevity. Below is a detailed overview of the compatibility of this part with specific Cummins engines.

QSK60 Series

The QSK60 series engines, including the QSK60 G and QSK60 G CM2358, are designed for heavy-duty applications and require robust components to maintain efficiency. The Aftercooler Tube part 4067157 is engineered to fit these engines perfectly, providing a reliable connection between the turbocharger and the intake manifold. This ensures that the air entering the engine is cooled effectively, enhancing combustion efficiency and reducing the risk of engine overheating.

K110 Series

The K110 engine series, which includes the K110 model, is another beneficiary of the Aftercooler Tube part 4067157. This part is crucial in maintaining the K110 engine’s performance, especially in demanding conditions. The tube’s design allows for efficient heat exchange, which is vital for the engine’s overall cooling system. The compatibility of this part with the K110 series ensures that the engine operates at peak efficiency, providing the necessary power and reliability for various applications.

QSK60G

The QSK60G engine, part of the broader QSK60 series, also integrates the Aftercooler Tube part 4067157. This engine is known for its durability and high performance, making it a popular choice in industries that require robust machinery. The Aftercooler Tube’s precise fit and construction ensure that the QSK60G engine maintains optimal cooling, contributing to its longevity and consistent performance.

Conclusion

The Cummins Aftercooler Tube part 4067157 is a critical component for the QSK60 G, QSK60 G CM2358, K110, and QSK60G engines. Its design and engineering ensure that these engines operate efficiently and reliably, making it an essential part for maintaining the performance and longevity of these heavy-duty engines 4.

Role of Part 4067157 Aftercooler Tube in Engine Systems

The aftercooler tube, identified by part number 4067157, is an integral component in the aftercooling process of engine systems. Its primary function is to facilitate the transfer of cooled air from the aftercooler to the intake manifold. This process is essential for optimizing engine performance and efficiency.

Integration with the Aftercooler

The aftercooler tube connects directly to the aftercooler, which is a heat exchanger designed to cool the compressed air from the turbocharger before it enters the engine’s combustion chambers. By reducing the temperature of the intake air, the aftercooler increases its density, allowing more air to enter the cylinders and enhancing combustion efficiency 1.

Connection to the Intake Manifold

Once the air is cooled in the aftercooler, the aftercooler tube transports it to the intake manifold. This manifold distributes the cooled air to the individual cylinders, ensuring a consistent and efficient air supply across the engine. The effective design of the aftercooler tube minimizes pressure loss and ensures that the cooled air reaches the cylinders without significant temperature rise 2.

Contribution to Engine Performance

The efficient transfer of cooled air via the aftercooler tube plays a significant role in maintaining optimal engine performance. By ensuring that the intake air is at the correct temperature and pressure, the aftercooler tube helps to maximize power output, improve fuel efficiency, and reduce emissions. Additionally, it contributes to the overall reliability and longevity of the engine by preventing overheating and maintaining consistent combustion conditions 3.

Role in Turbocharged Engines

In turbocharged engine systems, the aftercooler tube is particularly important. Turbochargers compress intake air, which increases its temperature. The aftercooler tube works in conjunction with the aftercooler to cool this compressed air, preventing issues such as detonation and pre-ignition, which can damage the engine. This cooling process is vital for achieving the performance benefits that turbochargers provide 4.

Summary of Component Interaction

The aftercooler tube (part 4067157) interacts seamlessly with the aftercooler and intake manifold to ensure that the engine receives a steady supply of cooled, dense air. This interaction is fundamental to the efficient operation of the engine, particularly in high-performance and turbocharged applications.

-

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩ ↩ ↩ -

Wang, Y. (2007). Introduction to Engine Valvetrains. SAE International.

↩ ↩ ↩ -

Bonnick, A. (2004). A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier.

↩ ↩ ↩ -

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.