This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

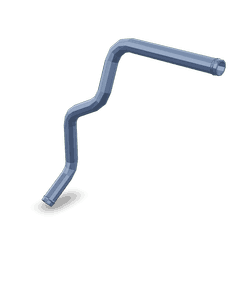

The 3934170 Aftercooler Tube is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This part is designed to play a specific role within the truck’s engine system, contributing to its overall performance and efficiency.

Basic Concepts of Aftercooler Tubes

An aftercooler tube is a component used in the engine system to cool compressed air before it enters the combustion chamber. By reducing the temperature of the air, the aftercooler tube helps to increase the density of the air, which in turn enhances the efficiency of the combustion process. This contributes to improved engine performance and fuel efficiency 1.

Purpose of the Aftercooler Tube 3934170

The 3934170 is designed to facilitate the cooling of compressed air within the engine system of a truck. By ensuring that the air entering the combustion chamber is at an optimal temperature, this component plays a role in enhancing engine efficiency and performance. It is an integral part of the engine’s air management system, working in conjunction with other components to maintain optimal operating conditions 2.

Key Features of the Aftercooler Tube 3934170

The 3934170 is characterized by several design elements that enhance its functionality and durability. These include a robust construction that can withstand the high pressures and temperatures within the engine system, as well as a precise fit that ensures efficient air flow and cooling. The material used in its construction is chosen for its resistance to corrosion and wear, ensuring long-term reliability 3.

Benefits of Using the Aftercooler Tube 3934170

The use of the 3934170 offers several advantages. By ensuring that the air entering the combustion chamber is at an optimal temperature, this component contributes to improved engine performance and increased fuel efficiency. Its durable construction and precise fit also enhance the overall reliability and longevity of the engine system 4.

Installation and Integration

Proper installation of the 3934170 is crucial for ensuring its effective operation within the engine system. This involves careful alignment and securing of the tube to prevent leaks and ensure efficient air flow. It is also important to follow any manufacturer guidelines regarding preparations or considerations for integration within the engine system.

Maintenance and Care

Regular maintenance and care of the 3934170 are important for ensuring optimal performance and longevity. This includes periodic inspection for signs of wear or damage, as well as cleaning to remove any buildup that could impede air flow. Following manufacturer guidelines for maintenance procedures can help to ensure the continued reliability of this component.

Troubleshooting Common Issues

Common issues that may arise with the 3934170 include leaks, reduced efficiency, and physical damage. Troubleshooting these issues involves a systematic approach to identifying the root cause, whether it be improper installation, wear and tear, or external factors. Solutions may range from simple repairs to replacement of the component, depending on the severity of the issue.

Performance Enhancements

There are potential performance enhancements or modifications that can be made to the 3934170 to further optimize engine efficiency and power output. These may involve upgrades to the material or design of the tube, or the integration of additional components to enhance its cooling capabilities. It is important to consult with a professional to determine the most appropriate enhancements for your specific engine system.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability within the automotive industry. The company’s commitment to these values is reflected in its diverse product offerings, which are designed to meet the needs of a wide range of applications and industries.

Cummins Aftercooler Tube 3934170 Compatibility

The Cummins Aftercooler Tube part number 3934170 is designed to fit seamlessly with several engine models, ensuring optimal performance and efficiency. This part is integral to the engine’s cooling system, specifically enhancing the aftercooling process which is crucial for maintaining engine efficiency and longevity.

Engine Models

- 6B5.9

The 3934170 Aftercooler Tube is engineered to integrate perfectly with the 6B5.9 engine. This engine model benefits from the precise fit and high-quality construction of the aftercooler tube, which helps in effectively cooling the compressed air before it enters the engine, thereby improving overall performance.

Compatibility and Performance

The compatibility of the 3934170 Aftercooler Tube with the 6B5.9 engine ensures that the engine operates at its peak efficiency. The tube’s design allows for efficient heat exchange, which is critical in maintaining the engine’s optimal temperature range. This results in better fuel economy, reduced emissions, and enhanced engine durability.

Installation and Maintenance

When installing the 3934170 Aftercooler Tube, it is essential to follow the manufacturer’s guidelines to ensure a proper fit and function. Regular maintenance checks should be performed to ensure the tube remains free from obstructions and leaks, which can affect the engine’s performance.

Importance of the Aftercooler Tube

The aftercooler tube plays a pivotal role in the engine’s cooling system. By cooling the compressed air, it reduces the temperature entering the engine, which helps in preventing overheating and ensures that the engine runs smoothly and efficiently. This component is a critical part of the engine’s overall cooling strategy, especially in high-performance and heavy-duty applications.

Role of Part 3934170 Aftercooler Tube in Engine Systems

The part 3934170 Aftercooler Tube is an integral component in the efficient operation of engine systems that incorporate aftercooling mechanisms. This tube facilitates the transfer of cooled air from the aftercooler to various parts of the engine, ensuring optimal performance and longevity of the engine components.

Integration with Plumbing Systems

In engine systems, the Aftercooler Tube is seamlessly integrated into the plumbing network. It connects the aftercooler to the intake manifold, allowing the cooled air to be distributed evenly throughout the engine. This integration is vital for maintaining consistent air pressure and temperature, which are essential for the efficient combustion process.

Interaction with Aftercooler Water Systems

The Aftercooler Tube also plays a significant role in systems that utilize water for cooling. In these setups, the tube is part of a closed-loop system where water is circulated through the aftercooler to absorb heat from the compressed air. The cooled air is then directed into the engine, while the heated water is sent back to the cooling system for temperature regulation. This continuous cycle ensures that the air entering the engine is at the optimal temperature, enhancing engine efficiency and reducing the risk of overheating.

Enhancing Engine Performance

By efficiently transferring cooled air, the Aftercooler Tube contributes to several key aspects of engine performance. It helps in reducing the temperature of the intake air, which in turn increases the air density. This denser air allows for more efficient combustion, leading to improved power output and fuel efficiency. Additionally, the reduced air temperature helps in minimizing thermal stress on engine components, thereby extending their operational lifespan.

Supporting System Reliability

The reliable operation of the Aftercooler Tube is fundamental to the overall reliability of the engine system. Any malfunction or blockage in this tube can lead to inefficient cooling, resulting in higher intake air temperatures. This can cause a cascade of issues, including reduced engine performance, increased fuel consumption, and potential damage to engine components due to overheating.

Conclusion

In summary, the 3934170 Aftercooler Tube is a key element in the plumbing and aftercooler water systems of engine setups. Its role in transferring cooled air ensures that the engine operates within optimal temperature ranges, enhancing performance, efficiency, and reliability.

-

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Reif, K. (Ed.). (2014). Brakes Brake Control and Driver Assistance Systems Function Regulation and Components. Springer.

↩ -

Wharton, A. J. (1991). Diesel Engines. Butterworth-Heinemann Ltd.

↩ -

Pulkrabek, W. W. (2014). Engineering Fundamentals of the Internal Combustion Engine. Pearson Education.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.