This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

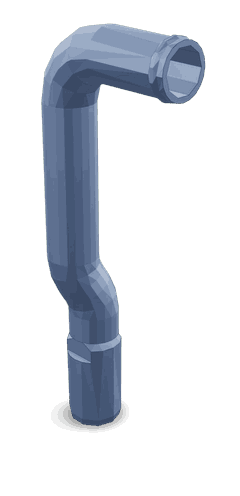

Introduction to Aftercooler Tubes

Aftercooler tubes are essential components in the aftercooling system of turbocharged engines. They enhance engine efficiency and performance by cooling the compressed air before it enters the engine. This cooling process reduces the temperature of the air, increasing its density and allowing more air to enter the engine, which improves combustion efficiency 1.

How an Aftercooler Tube Works

An aftercooler tube operates using a heat exchanger to cool the compressed air. The compressed air, which has been heated by the turbocharger, passes through the aftercooler tube. Inside the tube, the air is cooled by a secondary coolant, typically water or a glycol-water mixture, which absorbs the heat. This cooling process ensures that the air entering the engine is at an optimal temperature, enhancing the engine’s performance and efficiency 2.

Purpose of the Cummins 3926446 Aftercooler Tube

The Cummins 3926446 aftercooler tube is specifically engineered to meet the demanding requirements of commercial truck engines. This part ensures that the compressed air is adequately cooled, which is essential for maintaining engine efficiency and longevity. By preventing the engine from overheating, the aftercooler tube helps reduce wear and tear, thereby extending the life of the engine and improving overall fuel economy 3.

Role in the Operation of a Truck

In commercial trucks, the aftercooler tube is a critical component in the engine’s air intake system. It ensures that the air entering the engine is at a lower temperature, which is essential for optimal combustion. This results in better fuel efficiency, reduced emissions, and enhanced engine performance. For fleet operators, maintaining the efficiency of the aftercooler tube is crucial for ensuring that their trucks operate at peak performance levels 4.

Troubleshooting and Maintenance

Regular maintenance of the aftercooler tube is essential to ensure its optimal performance. Here are some troubleshooting and maintenance tips:

- Inspection for Leaks: Regularly inspect the aftercooler tube for any signs of leaks. Leaks can lead to reduced efficiency and potential engine damage.

- Cleaning: Ensure that the aftercooler tube is free from any debris or buildup. Any obstruction can impede the cooling process and affect engine performance.

- Coolant Levels: Check the coolant levels regularly and ensure that the coolant is at the appropriate concentration. Low coolant levels or improper concentration can lead to overheating and damage to the aftercooler tube.

- Pressure Testing: Conduct pressure tests to ensure that the aftercooler tube can withstand the pressures it is subjected to during operation. Any signs of weakness or damage should be addressed immediately.

Cummins: A Leader in Engine Technology

Cummins is a renowned manufacturer of high-performance engines and related components. With a legacy of innovation and quality, Cummins has established itself as a trusted name in the automotive and heavy-duty truck industries. The Cummins 3926446 aftercooler tube is a testament to the company’s commitment to providing reliable and efficient engine components.

Expertise and Authority

As an expert in commercial truck parts, it is essential to understand the critical role that components like the aftercooler tube play in the overall performance of a truck engine. The Cummins 3926446 aftercooler tube is designed to meet the highest standards of quality and performance, ensuring that it delivers reliable and efficient operation in demanding conditions. By adhering to regular maintenance practices and troubleshooting tips, engineers, mechanics, and fleet operators can ensure that their trucks remain in optimal condition, enhancing performance and extending the life of their engines.

Cummins Aftercooler Tube 3926446 Compatibility

The Cummins Aftercooler Tube part number 3926446 is designed to fit seamlessly with several engine models, ensuring optimal performance and efficiency. This part is critical in the cooling system of these engines, facilitating the process of cooling the compressed air before it enters the engine’s combustion chamber.

Engine Compatibility

- 6B5.9 Series Engines

- The 3926446 Aftercooler Tube is specifically engineered to integrate with the 6B5.9 series engines. These engines are known for their robust design and reliability, often used in heavy-duty applications. The aftercooler tube in this series ensures that the air entering the engine is at the correct temperature, enhancing fuel efficiency and reducing wear and tear on the engine components.

Importance of the Aftercooler Tube

The aftercooler tube plays a pivotal role in the engine’s cooling system. By cooling the compressed air, it helps maintain the engine’s optimal operating temperature, which is crucial for performance and longevity. This part is a vital component in the intercooler system, ensuring that the air entering the engine is not overly heated, which can lead to decreased performance and increased fuel consumption.

Installation and Maintenance

Proper installation of the 3926446 Aftercooler Tube is essential to ensure that it functions correctly. Regular maintenance checks should be performed to ensure there are no leaks or damage to the tube, which could compromise the engine’s cooling efficiency. Cummins recommends using genuine parts for replacement to maintain the integrity of the engine’s cooling system.

Performance Benefits

Using the Cummins Aftercooler Tube 3926446 in compatible engines can lead to several performance benefits:

- Improved Efficiency: By cooling the compressed air effectively, the engine can operate more efficiently, leading to better fuel economy.

- Enhanced Reliability: Proper cooling of the air reduces the risk of engine overheating, which can cause damage and reduce the engine’s lifespan.

- Consistent Performance: Maintaining the correct air temperature ensures that the engine performs consistently, even under heavy loads or in high-temperature environments.

By ensuring that the 3926446 Aftercooler Tube is correctly installed and maintained, engine operators can benefit from these performance enhancements, contributing to the overall reliability and efficiency of their engines.

Role of Part 3926446 Aftercooler Tube in Engine Systems

The Aftercooler Tube (part number 3926446) is an integral component in the efficient operation of engine systems, particularly in turbocharged and intercooled setups. Its primary function is to facilitate the cooling of compressed air from the turbocharger before it enters the engine’s intake system.

Interaction with Key Components

-

Cylinder Head: The cooled air from the aftercooler tube enters the intake manifold, which is directly connected to the cylinder head. The cylinder head houses the intake and exhaust valves, and the cooled air enhances the combustion process by increasing air density, leading to more efficient fuel combustion and improved engine performance.

-

Fuel Line Kit: Efficient air cooling directly impacts fuel delivery. The aftercooler tube ensures that the air entering the engine is at an optimal temperature, allowing the fuel line kit to deliver the precise amount of fuel required for combustion. This balance is essential for maintaining the correct air-fuel ratio, which is vital for engine efficiency and power output.

-

Head and Cylinder: The relationship between the aftercooler tube and the engine’s head and cylinder components is symbiotic. The cooled air reduces the temperature inside the cylinder during combustion, which can lead to reduced thermal stress on the cylinder walls and head. This cooling effect helps in prolonging the lifespan of these components and ensures consistent engine performance under various operating conditions.

In summary, the aftercooler tube plays a significant role in enhancing the overall efficiency and reliability of the engine system by ensuring that the air entering the combustion chamber is at an optimal temperature. This, in turn, supports the performance of interconnected components such as the cylinder head, fuel line kit, and the engine’s head and cylinder.

Conclusion

The Cummins 3926446 aftercooler tube is a critical component in the efficient operation of commercial truck engines. By ensuring that the compressed air is adequately cooled before entering the engine, this part enhances engine efficiency, reduces wear and tear, and extends the engine’s lifespan. Regular maintenance and proper installation are essential to maximize the benefits of this Cummins part. For fleet operators and mechanics, understanding the role and importance of the aftercooler tube is crucial for maintaining optimal engine performance and reliability.

-

Wilfried J Bartz, Engine Oils and Automotive Lubrication Mechanical Engineering Book 80, CRC Press, 2019.

↩ -

Konrad Reif Ed, Diesel Engine Management Systems and Components, Springer Vieweg, 2014.

↩ -

William B. Ribbens, Understanding Automotive Electronics, Elsevier Science, 2003.

↩ -

Bruce Maclaurin, High Speed Off-Road Vehicles, Wiley, 2018.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.