This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3914502 Aftercooler is a component designed for use in commercial trucks. It enhances engine efficiency and performance by cooling compressed air from the turbocharger before it enters the engine cylinders. This cooling process increases air density, improving combustion efficiency and power output 3.

Basic Concepts of Aftercoolers

An aftercooler, also known as an intercooler, cools compressed air from a turbocharger or supercharger. This process increases the air’s density, allowing more oxygen to enter the engine, which enhances combustion efficiency. Aftercoolers use air cooling technology, where compressed air passes through a series of tubes or fins exposed to ambient air, facilitating heat exchange and reducing the temperature of the air 2.

Purpose of the 3914502 Aftercooler

The Cummins 3914502 Aftercooler cools the compressed air from the turbocharger, increasing air density for more efficient combustion and improved engine performance. It also reduces thermal stress on engine components, contributing to overall engine efficiency and longevity 3.

Key Features

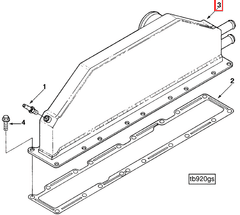

The Cummins 3914502 Aftercooler features a robust design and high-quality materials. It has a compact yet efficient structure with multiple tubes or fins to maximize the surface area for heat exchange. Constructed from durable materials, it withstands the harsh conditions of commercial truck operations, ensuring reliable performance over time 1.

Benefits of Using the 3914502 Aftercooler

Using the Cummins 3914502 Aftercooler enhances engine performance by ensuring optimal air density for combustion, resulting in increased power output and improved fuel efficiency. It also contributes to engine durability by reducing thermal stress on critical components, leading to longer engine life and reduced maintenance costs 3.

Installation and Integration

Installing the Cummins 3914502 Aftercooler involves integrating it into the truck’s engine system to ensure efficient airflow and heat exchange. Proper alignment with the turbocharger and secure mounting to prevent vibrations are crucial. Following the manufacturer’s guidelines ensures correct installation and optimal performance 1.

Maintenance and Care

Regular maintenance is recommended to ensure the longevity and optimal performance of the Cummins 3914502 Aftercooler. This includes inspecting for damage or wear, cleaning the fins and tubes to remove debris, and ensuring all connections are secure. Adhering to a routine maintenance schedule maintains the efficiency of the aftercooler and the overall engine system 1.

Troubleshooting Common Issues

Common issues with aftercoolers may include reduced efficiency due to clogged fins or tubes, leaks, or physical damage. Troubleshooting steps involve inspecting for visible damage, cleaning the fins and tubes to restore airflow, and checking for leaks. Addressing these issues promptly maintains the performance of the aftercooler and the engine 1.

Performance Enhancements

The Cummins 3914502 Aftercooler contributes to overall truck performance by ensuring the engine receives cool, dense air for combustion. This results in more efficient fuel burning, increased power output, and improved engine responsiveness. Compared to standard models, the 3914502 Aftercooler offers enhanced cooling efficiency, leading to better engine performance and fuel economy 3.

Environmental Impact

The use of the Cummins 3914502 Aftercooler has positive environmental implications. By improving engine efficiency and reducing the amount of fuel needed for combustion, it contributes to lower emissions. Additionally, increased fuel efficiency leads to reduced fuel consumption, which is beneficial for the environment. The aftercooler promotes sustainable trucking operations by enhancing engine performance while minimizing environmental impact 3.

Cummins Overview

Cummins Inc. is a renowned manufacturer in the commercial truck industry, known for innovation and quality in engine components. The company is committed to developing advanced technologies that improve engine performance, efficiency, and durability. Cummins’ reputation for reliability and excellence underscores its dedication to providing high-quality engine components, including the Cummins 3914502 Aftercooler 3.

Compatibility of Cummins Aftercooler Part 3914502

The Cummins part 3914502 Aftercooler is designed to enhance the performance and efficiency of specific engine models. It is engineered to work seamlessly with the following engines:

- 6C8.3

- ISC CM554

- QSC8.3 CM554

These engines, while distinct in their configurations and applications, share a commonality in their need for an efficient aftercooling system. The part 3914502 is meticulously crafted to fit these engines, ensuring optimal performance and longevity.

For the 6C8.3 engine, the aftercooler plays a pivotal role in managing the intake air temperature, which is crucial for maintaining the engine’s efficiency and power output. Similarly, for the ISC CM554 and QSC8.3 CM554, the aftercooler’s design is tailored to handle the specific demands of these engines, ensuring that the intake air is cooled effectively before it enters the combustion chamber.

The integration of the Cummins part 3914502 Aftercooler with these engines is a testament to Cummins’ commitment to providing high-quality, reliable components that enhance engine performance and durability 3.

Role of Part 3914502 Aftercooler in Engine Systems

In the context of engine systems, the part 3914502 Aftercooler is integral to the efficient operation of several key components. Its primary function is to reduce the temperature of compressed air from the turbocharger before it enters the engine’s combustion chamber.

Interaction with Turbocharger

The turbocharger compresses intake air to increase engine efficiency and power output. However, this compression process generates heat, which can lead to decreased air density and potential engine knocking. The Aftercooler mitigates these issues by cooling the compressed air, thereby enhancing the turbocharger’s effectiveness and ensuring optimal engine performance 2.

Integration with Jacket Water Aftercooler

In systems that employ a jacket water aftercooler, the 3914502 Aftercooler works in tandem to further reduce the temperature of the air. The jacket water aftercooler uses engine coolant to pre-cool the air before it passes through the 3914502 Aftercooler. This two-stage cooling process ensures that the air entering the engine is at an ideal temperature, maximizing combustion efficiency and protecting engine components from thermal stress 2.

Placement in Turbocharger Arrangement

The location of the turbocharger within the engine arrangement significantly influences the effectiveness of the Aftercooler. In a twin-turbo setup, for instance, the Aftercooler is positioned between the turbochargers and the engine intake. This arrangement allows for sequential cooling of the air, first by the primary turbocharger, then by the Aftercooler, and finally by the secondary turbocharger. This setup not only enhances engine performance but also ensures that the air-fuel mixture is at an optimal temperature for combustion 2.

Overall System Benefits

By effectively cooling the compressed air, the 3914502 Aftercooler plays a vital role in maintaining the overall efficiency and reliability of the engine system. It ensures that the air entering the combustion chamber is dense and cool, which is essential for achieving peak performance and longevity of engine components 3.

Conclusion

The Cummins 3914502 Aftercooler is a critical component in enhancing the performance and efficiency of commercial truck engines. By cooling the compressed air from the turbocharger, it increases air density, improves combustion efficiency, and contributes to the overall durability and longevity of the engine. Regular maintenance and proper installation are essential to ensure optimal performance and longevity of this Cummins part.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.