This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

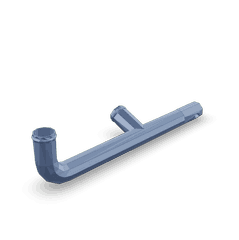

The Aftercooler Tube 3899720, manufactured by Cummins, is a component designed to enhance the efficiency and performance of heavy-duty truck engines. Aftercooler tubes play a significant role in the engine system by facilitating the cooling of compressed air from the turbocharger before it enters the engine cylinders. This process is vital for maintaining optimal engine performance and longevity 1.

Basic Concepts of Aftercooler Tubes

An aftercooler tube is a part of the engine cooling system that cools the compressed air from the turbocharger. This cooling process increases the density of the air, allowing more oxygen to enter the engine cylinders. This, in turn, enhances combustion efficiency and power output. Aftercoolers work on the principle of air cooling, where the heat from the compressed air is transferred to a cooling medium, typically ambient air, through the walls of the aftercooler tube 2.

Purpose of the Aftercooler Tube 3899720

The Aftercooler Tube 3899720 is specifically designed to cool the compressed air from the turbocharger in heavy-duty truck engines. By reducing the temperature of the air before it enters the engine cylinders, this component contributes to the efficiency and performance of the engine. Cooler air is denser, which allows for more efficient combustion and increased power output. Additionally, it reduces thermal stress on engine components, leading to improved durability and reliability 3.

Key Features

The Aftercooler Tube 3899720 is constructed from high-quality materials that ensure durability and efficient heat transfer. Its design includes features that enhance its functionality, such as a robust structure that can withstand high pressures and temperatures. The tube is also engineered to facilitate easy installation and integration into the engine system, ensuring it meets the demanding requirements of heavy-duty applications 4.

Benefits

Utilizing the Aftercooler Tube 3899720 offers several benefits, including improved engine efficiency through more effective air cooling. This results in enhanced combustion and increased power output. Additionally, by reducing thermal stress on engine components, the tube contributes to the overall reliability and longevity of the engine. The enhanced cooling also leads to better fuel efficiency, making it a valuable component for heavy-duty truck engines 1.

Installation and Integration

Proper installation of the Aftercooler Tube 3899720 is crucial for ensuring it functions correctly within the engine system. The installation process involves several steps, including preparing the engine compartment, aligning the tube with the turbocharger and engine inlet, and securing it in place. Tools required for installation may include wrenches, gaskets, and sealants. Following the manufacturer’s guidelines ensures the tube is correctly integrated into the engine system 4.

Troubleshooting and Maintenance

Common issues with the Aftercooler Tube 3899720 may include leaks, blockages, or damage from extreme temperatures or pressures. Diagnosing these problems involves inspecting the tube for signs of wear, damage, or improper installation. Regular maintenance, such as cleaning and checking for leaks, can help ensure the longevity and optimal performance of the tube. It is also important to monitor the engine’s performance for any signs of reduced efficiency, which may indicate issues with the aftercooler tube 2.

Performance Enhancements

The Aftercooler Tube 3899720 contributes to overall engine performance by ensuring that the air entering the engine cylinders is at an optimal temperature. This leads to more efficient combustion, increased power output, and improved fuel efficiency. Effective cooling also reduces thermal stress on engine components, contributing to the engine’s durability and reliability. The interplay between effective cooling and engine longevity is a key factor in the performance enhancements provided by this component 3.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s commitment to developing high-performance, reliable engine components is evident in its product range, which includes the Aftercooler Tube 3899720. Cummins’ focus on innovation and quality ensures that its components meet the demanding requirements of heavy-duty applications 4.

Aftercooler Tube (Part 3899720) Compatibility with Cummins Engines

The Aftercooler Tube, part number 3899720, is a critical component in the cooling system of certain Cummins engines. This part is designed to fit seamlessly with specific models, ensuring optimal performance and longevity of the engine.

M11 CELECT PLUS

The M11 CELECT PLUS engine benefits from the Aftercooler Tube in maintaining efficient cooling. This part is integral to the engine’s ability to manage heat effectively, which is crucial for maintaining peak performance levels. The Aftercooler Tube ensures that the air entering the engine is at the correct temperature, enhancing the engine’s overall efficiency and reliability 4.

M11 MECHANICAL

Similarly, the M11 MECHANICAL engine relies on the Aftercooler Tube to maintain its cooling system’s integrity. This part plays a vital role in the engine’s cooling process, ensuring that the air intake is properly managed. By doing so, it helps in reducing the engine’s operating temperature, which is essential for preventing overheating and extending the engine’s lifespan 4.

Grouping of Engines

Both the M11 CELECT PLUS and M11 MECHANICAL engines share a common requirement for the Aftercooler Tube. This part is essential for the cooling systems of these engines, ensuring that they operate within optimal temperature ranges. The compatibility of the Aftercooler Tube with these engines underscores its importance in maintaining the efficiency and reliability of the M11 series engines 4.

Role of Part 3899720 Aftercooler Tube in Engine Systems

The part 3899720 Aftercooler Tube is an integral component in the efficient operation of engine systems that incorporate aftercooling technology. This tube facilitates the connection between various components within the aftercooling circuit, ensuring optimal performance and reliability.

Integration with Plumbing Systems

In engine systems, the Aftercooler Tube is seamlessly integrated into the plumbing network. It acts as a conduit for the flow of coolant or air, depending on the specific aftercooling method employed. Whether it’s liquid or air-based aftercooling, this tube ensures a smooth and uninterrupted transfer of the cooling medium. Its precise fit and durable construction contribute to the overall integrity of the plumbing system, minimizing the risk of leaks or disruptions 1.

Collaboration with Aftercooler Water Components

When it comes to aftercooler water systems, the Aftercooler Tube plays a pivotal role in maintaining the desired temperature levels. It connects the aftercooler water reservoir to the aftercooler unit, allowing for the circulation of water as a cooling agent. This tube ensures that the water reaches the aftercooler efficiently, enhancing the cooling process and contributing to the engine’s overall performance. Its design is tailored to accommodate the specific requirements of aftercooler water systems, promoting effective heat dissipation 2.

Enhancing Engine Efficiency

By facilitating the proper flow of cooling mediums, the Aftercooler Tube contributes to the engine’s efficiency. In liquid-based systems, it ensures that the coolant reaches the aftercooler at the right temperature and pressure, optimizing the cooling process. In air-based systems, it allows for the efficient transfer of cooled air to the engine components, reducing thermal stress and improving overall performance. This tube’s role in maintaining the right conditions within the aftercooling circuit is essential for the engine’s longevity and reliability 3.

Reliable Performance in Diverse Applications

The Aftercooler Tube’s versatility allows it to be utilized in a wide range of engine applications. Whether in industrial machinery, automotive engines, or marine propulsion systems, this tube adapts to the specific demands of each application. Its robust construction and precise fit ensure consistent performance, making it a reliable component in various engine systems 4.

Conclusion

The Aftercooler Tube 3899720 is a vital component in the efficient operation of heavy-duty truck engines. Its role in cooling compressed air from the turbocharger enhances engine performance, efficiency, and longevity. Proper installation, regular maintenance, and understanding its compatibility with specific engine models are crucial for maximizing the benefits of this Cummins part. The Aftercooler Tube’s integration with plumbing and aftercooler water components ensures efficient cooling and reliable operation across a spectrum of applications.

-

Lejda, K., & Wos, P. (2012). Internal Combustion Engines. InTech.

↩ ↩ ↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International.

↩ ↩ ↩ -

Arora, S., Abkenar, A. T., & Jayasi, S. G. (2021). Heavyduty Electric Vehicles: From Concept to Reality. Elsevier.

↩ ↩ ↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4388602.

↩ ↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.