3627382

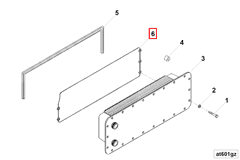

Aftercooler Core Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Aftercooler Core Seal, identified by part number 3627382, is a component manufactured by Cummins, a prominent name in the diesel engine industry. This seal is integral to the cooling system of heavy-duty truck engines, ensuring the efficient operation of the aftercooler. Cummins, known for its robust and reliable engine components, designs this seal to meet the demanding requirements of commercial vehicle applications 1.

Function and Operation

The Aftercooler Core Seal operates within the engine’s cooling system by maintaining the integrity of the seal between the aftercooler core and the surrounding housing. Its primary role is to prevent coolant leaks, which could lead to inefficient cooling and potential engine damage. By ensuring a tight seal, it allows the aftercooler to effectively reduce the temperature of the compressed air from the turbocharger before it enters the engine cylinders, contributing to overall engine efficiency 2.

Purpose of the Aftercooler Core Seal

In the operation of a heavy-duty truck, the Aftercooler Core Seal plays a specific role by enhancing the efficiency and performance of the engine. It ensures that the aftercooler functions optimally by maintaining a secure seal, which is vital for the effective cooling of the compressed air. This cooling process is crucial for reducing the temperature of the air entering the engine, which in turn helps in achieving better combustion efficiency and reducing the risk of engine knocking 3.

Key Features

The Aftercooler Core Seal is characterized by several key features that enhance its functionality. It is typically made from durable materials that can withstand the high temperatures and pressures within the engine cooling system. The design of the seal is tailored to fit precisely within the aftercooler assembly, ensuring a reliable seal. Additionally, it may incorporate features such as reinforced edges or specialized coatings to improve its durability and resistance to wear.

Benefits

The advantages provided by the Aftercooler Core Seal include improved engine reliability through effective cooling, which helps in maintaining optimal engine operating temperatures. Enhanced cooling efficiency leads to better overall engine performance and fuel efficiency. For fleet operators, the use of a high-quality aftercooler core seal can result in potential cost savings by reducing the frequency of repairs and maintenance associated with coolant leaks and engine overheating.

Installation and Compatibility

Proper installation of the Aftercooler Core Seal is crucial for ensuring optimal performance. It should be installed according to the manufacturer’s guidelines, which may include specific torque settings for fasteners and the use of recommended sealants or gaskets. Ensuring that the seal is correctly positioned and that all connections are secure will help in achieving the desired sealing effect and preventing leaks.

Maintenance and Troubleshooting

Routine maintenance practices for the Aftercooler Core Seal include regular inspections for signs of wear or damage, such as cracks or deformations. It is also important to check for any leaks in the cooling system, as these could indicate a failing seal. Troubleshooting common issues may involve replacing the seal if leaks are detected or addressing any misalignments in the aftercooler assembly that could affect the seal’s performance.

Cummins Overview

Cummins is a leading manufacturer of diesel engines and related components for commercial vehicles. With a reputation for quality and reliability, Cummins components are designed to meet the rigorous demands of heavy-duty applications. The company’s commitment to innovation and excellence in engine technology makes it a trusted choice for fleet operators and maintenance professionals alike.

Cummins Aftercooler Core Seal (Part 3627382) Compatibility

The Cummins Aftercooler Core Seal, identified by the part number 3627382, is a critical component designed to ensure the integrity of the aftercooling system in various engine configurations. This seal is specifically engineered to fit seamlessly with the K50 engine series, providing a reliable barrier against leaks and maintaining optimal system pressure.

In the K50 engine family, the aftercooler core seal is essential for preventing air and coolant from mixing, which could otherwise lead to decreased efficiency and potential engine damage. The seal’s design ensures a tight fit around the core, effectively sealing off the aftercooler from the rest of the engine’s air intake system.

This part is not limited to a single engine model within the K50 series but is compatible across multiple configurations. Its universal fitment across various K50 engines underscores its versatility and importance in maintaining the performance and longevity of the engine.

Role of Part 3627382 Aftercooler Core Seal in Engine Systems

The Aftercooler Core Seal (part 3627382) is integral to the efficient operation of various engine components. Its primary function is to ensure a secure seal within the Aftercooler Core, preventing any unwanted leaks that could compromise performance.

In the context of the Aftercooler Mounting Core, this seal plays a supportive role by maintaining the integrity of the mounting structure. A well-sealed aftercooler ensures that the mounting core remains stable and functions as intended, contributing to the overall reliability of the engine system.

When considering the Aftercooler Plumbing, the seal is essential for maintaining the correct pressure and flow of coolant or air through the system. This is vital for optimal heat exchange, which directly impacts the engine’s performance and longevity.

The interaction between the Turbocharger and the aftercooler is also influenced by the effectiveness of the seal. A properly sealed aftercooler core allows the turbocharger to operate more efficiently by ensuring that the air entering the engine is at the desired temperature and pressure.

In the broader engine arrangement, the seal contributes to the stability and performance of components such as the Camshaft and Gear. By ensuring that the aftercooler operates efficiently, the seal helps maintain consistent engine temperatures, which is beneficial for the longevity and performance of these mechanical parts.

The Lower Engine Gasket Kit and Upper Engine Gasket Kit also benefit from the presence of a reliable aftercooler core seal. These gaskets are designed to prevent leaks and maintain pressure within the engine. A well-sealed aftercooler core complements these gaskets by ensuring that the entire engine system operates within the designed parameters.

Additionally, components like the Oil Control Valve rely on stable engine conditions to function correctly. The aftercooler core seal contributes to this stability by ensuring that the air entering the engine is properly cooled, which can affect oil viscosity and, consequently, the performance of the oil control valve.

Conclusion

In summary, the Aftercooler Core Seal (part 3627382) is a key component in maintaining the efficiency and reliability of various engine systems. Its role in sealing the aftercooler core has a cascading effect on the performance of interconnected parts, ultimately contributing to the engine’s overall performance and durability.

-

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩ -

Halderman, J. D. (2012). Automotive Principles: Diagnosis and Service. Prentice Hall.

↩ -

ElSayed, M. (2017). Fundamentals of Integrated Vehicle Realization. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.