This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

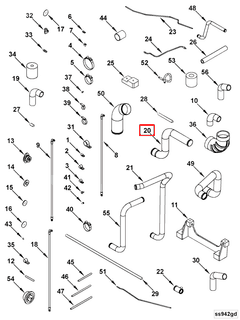

The Cummins Aftercooler Tube, part number 3284795, is a component designed to enhance the efficiency and reliability of engine systems in heavy-duty trucks. Its primary role is within the engine cooling system, where it contributes to the optimal operation of the engine by managing the temperature of the compressed air from the turbocharger before it enters the engine cylinders.

Function and Operation

The Aftercooler Tube operates by facilitating the cooling of compressed air from the turbocharger. This cooling process is vital as it reduces the temperature of the air before it enters the engine cylinders, which in turn helps in achieving more efficient combustion. By lowering the air temperature, the density of the air increases, allowing for more air to enter the cylinders and thus enhancing the combustion process. This component is integral to maintaining the desired temperature levels within the engine system, ensuring that the engine operates within its optimal temperature range 1.

Key Features

The design and construction of the Aftercooler Tube are tailored to meet the demanding requirements of heavy-duty engine systems. It is made from high-quality materials that offer durability and resistance to the high pressures and temperatures encountered in engine operations. The tube features precise connection points that ensure a secure fit within the engine system, minimizing the risk of leaks and ensuring efficient operation. Additionally, its design may include features that enhance heat exchange efficiency, contributing to its overall performance and longevity 2.

Benefits of Using Aftercooler Tube 3284795

Incorporating the Aftercooler Tube into an engine system offers several advantages. It contributes to improved engine efficiency by ensuring that the air entering the cylinders is at an optimal temperature for combustion. This can lead to reduced thermal stress on engine components, potentially extending the lifespan of the engine. Furthermore, by enhancing the efficiency of the combustion process, it may also contribute to reductions in fuel consumption and emissions, aligning with broader goals of environmental sustainability and operational cost efficiency 3.

Installation and Compatibility

Proper installation of the Aftercooler Tube is crucial for ensuring its effective operation within the engine system. Installation procedures should follow manufacturer guidelines to ensure compatibility and optimal performance. It is important to verify that all prerequisites are met and that any additional components required for installation are in place. Compatibility with specific engine models and systems should be confirmed to ensure seamless integration and operation 4.

Maintenance and Troubleshooting

Regular maintenance of the Aftercooler Tube is recommended to ensure its continued optimal functioning. This may include periodic inspections for signs of wear or damage, ensuring connection points remain secure, and verifying that the tube is free from obstructions that could impede airflow. Common issues that may arise include leaks or reduced efficiency, which can often be addressed through routine maintenance practices. Should issues persist, troubleshooting steps may involve more detailed inspections or consultations with technical resources.

Performance Impact

The Aftercooler Tube plays a role in enhancing overall engine performance by contributing to more efficient combustion processes. This can lead to improvements in fuel efficiency and reductions in emissions. Real-world applications have demonstrated the benefits of incorporating this component into engine systems, with reports indicating enhancements in engine reliability and operational efficiency.

Manufacturer - Cummins

Cummins is a renowned manufacturer in the heavy-duty truck industry, with a history of innovation and quality in engine technology. Their reputation is built on a commitment to producing reliable and efficient engine components, including the Aftercooler Tube. Cummins offers a wide range of products designed to meet the diverse needs of heavy-duty truck operators, emphasizing performance, durability, and compatibility with various engine systems.

Cummins Aftercooler Tube 3284795 Compatibility

The Cummins Aftercooler Tube part number 3284795 is designed to fit seamlessly within various engine models. This part is integral to the engine’s cooling system, ensuring optimal performance and efficiency.

Engine Compatibility

-

6B5.9 Series

- The 3284795 Aftercooler Tube is specifically engineered to integrate with the 6B5.9 engine series. This compatibility ensures that the cooling system functions effectively, maintaining the engine’s temperature within safe operating limits.

-

Other Cummins Engines

- While the primary focus is on the 6B5.9 series, the 3284795 Aftercooler Tube may also be compatible with other Cummins engine models. It is essential to verify the specific engine model and configuration to ensure a proper fit.

Importance of the Aftercooler Tube

The Aftercooler Tube plays a role in the engine’s cooling system by facilitating the transfer of heat from the compressed air to the surrounding environment. This process helps in reducing the temperature of the air entering the engine, thereby improving overall efficiency and performance.

Installation and Maintenance

Proper installation of the Aftercooler Tube is vital to ensure the engine operates at peak performance. Regular maintenance checks should be conducted to verify the integrity of the tube and its connections, preventing potential leaks or failures that could compromise engine performance.

Role of Part 3284795 Aftercooler Tube in Engine Systems

The aftercooler tube, identified by part number 3284795, is integral to the efficient operation of an engine system. This component facilitates the transfer of air from the turbocharger to the aftercooler, where the air is cooled before entering the engine’s combustion chamber.

In the context of an engine installation kit, the aftercooler tube ensures that the cooled air maintains its temperature as it travels to the engine. This is vital for optimizing engine performance and fuel efficiency. The tube’s design allows for minimal heat transfer, preserving the air’s cooled state.

During the engine installation process, proper alignment and secure fitting of the aftercooler tube are essential. This ensures that there are no leaks in the air pathway, which could lead to a loss of efficiency and potential engine damage. The tube must be correctly positioned to handle the pressure differentials between the turbocharger and the aftercooler.

Conclusion

In summary, the Aftercooler Tube 3284795 plays a significant role in maintaining the integrity of the air cooling process within the engine system, directly influencing the engine’s overall performance and longevity. Its proper installation, maintenance, and compatibility with specific engine models are crucial for ensuring optimal engine operation and efficiency.

-

ElSayed, Mohamed PE. Fundamentals of Integrated Vehicle Realization. SAE International, 2017.

↩ -

ElGindy, Moustafa and ElSayegh, Zeinab. Road and Off-Road Vehicle Dynamics. Springer Nature, 2023.

↩ -

Parikyan, Tigran Ed. Advances in Engine and Powertrain Research and Technology. Springer Nature, 2022.

↩ -

Schneider, Wolf-Henning. Pistons and Engine Testing. Springer Nature, 2016.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.