This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Aftercooler Tube 3282123 is a component manufactured by Cummins, a prominent entity in the commercial truck industry. This tube is designed to facilitate the cooling process post-compression, which is essential for maintaining engine efficiency and performance.

Basic Concepts of Aftercooler Tubes

An aftercooler tube is a component of the engine cooling system that aids in reducing the temperature of compressed air before it enters the engine’s combustion chamber. This cooling process is vital for the longevity and reliability of the engine, as it prevents overheating and reduces the risk of thermal stress on engine components 1.

Purpose of the 3282123 Aftercooler Tube

The 3282123 Aftercooler Tube is engineered to enhance the operation of trucks by ensuring that the air entering the engine is at an optimal temperature. This contributes to improved engine efficiency, as cooler air is denser and allows for more complete combustion. Additionally, the tube helps in reducing the wear and tear on engine parts, leading to better overall performance and reliability of the truck 2.

Key Features

The 3282123 Aftercooler Tube is constructed from high-quality materials that offer durability and resistance to corrosion. The design includes precise engineering to ensure efficient airflow and effective cooling. It may also feature reinforced sections to withstand high pressure and temperature fluctuations, ensuring long-lasting performance 3.

Benefits of Using the 3282123 Aftercooler Tube

Utilizing the 3282123 Aftercooler Tube offers several advantages. It contributes to improved engine performance by ensuring that the air entering the engine is at the optimal temperature for combustion. This leads to increased efficiency and power output. Furthermore, the durable construction of the tube enhances its longevity, potentially reducing the need for frequent replacements and offering cost savings for fleet operators. The efficient cooling provided by the tube also helps in maintaining the overall health of the engine, leading to reduced maintenance costs over time.

Installation Process

Installing the 3282123 Aftercooler Tube requires careful attention to detail to ensure proper functionality. The process involves disconnecting the old tube, cleaning the connection points, and securely attaching the new tube. It is important to use the correct tools and equipment to avoid damaging the tube or the surrounding components. Ensuring that all connections are tight and secure is crucial for the tube to perform its cooling function effectively.

Troubleshooting Common Issues

Common issues with the 3282123 Aftercooler Tube may include leaks, blockages, or reduced cooling efficiency. To address these problems, it is important to inspect the tube for any signs of damage or wear. Cleaning the tube and ensuring that all connections are secure can help resolve many issues. If the tube is damaged beyond repair, replacement may be necessary to restore optimal engine performance.

Maintenance Tips

Regular maintenance of the 3282123 Aftercooler Tube is important for ensuring its longevity and optimal performance. This includes periodic inspections for signs of wear or damage, cleaning the tube to remove any buildup that may impede airflow, and ensuring that all connections are secure. Following the manufacturer’s recommended maintenance schedule can help prevent issues and ensure that the tube continues to function effectively.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to innovation and quality. With a history of producing reliable and high-performance engines and components, Cummins has established a strong reputation within the industry. The company offers a wide range of products designed to meet the diverse needs of fleet operators, emphasizing durability, efficiency, and performance. Cummins’ dedication to research and development ensures that its products continue to evolve, providing cutting-edge solutions for the commercial trucking sector.

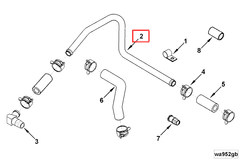

Role of Part 3282123 Aftercooler Tube in Aftercooler Plumbing

The aftercooler tube, identified by part number 3282123, is integral to the efficient operation of aftercooler plumbing systems. This component facilitates the transfer of cooled air from the aftercooler to various parts of the engine system, ensuring optimal performance and longevity of the engine.

Integration with Aftercooler Plumbing

In the context of aftercooler plumbing, the aftercooler tube plays a significant role in directing the flow of air that has been cooled by the aftercooler. This cooled air is essential for reducing the temperature of the compressed air before it enters the engine’s intake system. By maintaining lower temperatures, the aftercooler tube helps in enhancing the efficiency of the combustion process and reducing thermal stress on engine components.

Interaction with Other Components

-

Intercooler: The aftercooler tube often connects to an intercooler, where the air is further cooled before entering the engine. This sequential cooling process ensures that the air entering the engine is at an optimal temperature, promoting better fuel efficiency and power output.

-

Turbocharger: In turbocharged engines, the aftercooler tube is positioned between the turbocharger and the intercooler. This setup allows the turbocharger to compress the air, which is then cooled by the aftercooler before being further cooled by the intercooler. The aftercooler tube ensures a smooth transition of air between these components, maintaining the integrity of the air flow.

-

Intake Manifold: The cooled air from the aftercooler, transported via the aftercooler tube, is directed towards the intake manifold. This ensures that the air-fuel mixture entering the combustion chambers is at an ideal temperature, which is vital for consistent engine performance and reduced emissions.

-

Sensors and Actuators: Modern engine systems are equipped with various sensors and actuators that monitor and control the air flow. The aftercooler tube interacts with these components by providing a consistent and cool air supply, which is necessary for the accurate functioning of these sensors and actuators.

Benefits of Efficient Aftercooler Tube Usage

-

Enhanced Engine Performance: By ensuring that the air entering the engine is cool, the aftercooler tube contributes to more efficient combustion, leading to improved engine performance.

-

Reduced Thermal Stress: Lower air temperatures help in reducing thermal stress on engine components, leading to increased durability and reliability.

-

Improved Fuel Efficiency: Cooler air is denser, allowing for better fuel combustion and thus improving overall fuel efficiency.

-

Lower Emissions: Efficient cooling of the air before it enters the engine results in more complete combustion, which leads to reduced emissions.

Conclusion

In summary, the aftercooler tube (part 3282123) is a vital component in the aftercooler plumbing system, ensuring that the air supplied to the engine is cool and efficient, thereby supporting the overall performance and longevity of the engine system.

-

Composite Materials Handbook Volume 4 Metal Matrix Composites, SAE International, 2013

↩ -

SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety, R. Matthew Brach, SAE Books, 2023

↩ -

Fundamentals of Integrated Vehicle Realization, Mohamed ElSayed PE, SAE International, 2017

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.